PE film compounded antistatic EPE

An anti-static and film composite technology is applied in the direction of synthetic resin layered products, containers to prevent mechanical damage, flexible coverings, etc. It can solve the problems of poor toughness and fragility, and achieve moderate thickness, high tensile strength, soft texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

specific Embodiment approach

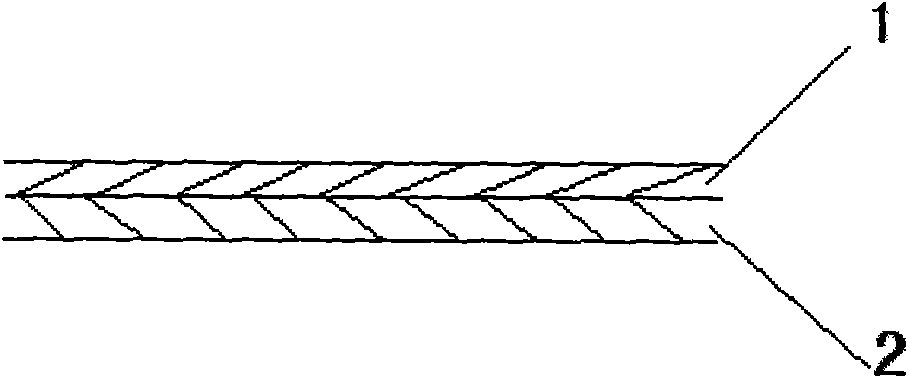

[0012] A PE film composite antistatic EPE comprises a PE film layer 1 and an antistatic EPE layer 2 compounded on the PE film layer, and the PE film and the antistatic EPE are bonded by hot melt. Antistatic EPE is made by adding antistatic agent to the raw material of EPE according to the conventional process. By adding antistatic agent, the surface of the product absorbs more moisture and forms a single molecular layer antistatic foam film, thereby accelerating the leakage of electrostatic charge. The surface resistance is about 10 6 -10 11 Ω, charge generation: (V) 2 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com