Build-up wear-resistant copper-based alloy

一种基合金、耐磨铜的技术,应用在金属材料涂层工艺、机器/发动机、机械设备等方向,能够解决不容易保持合金元素目标浓度等问题,达到满足抗裂性、改善抗裂性、良好平衡方式的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

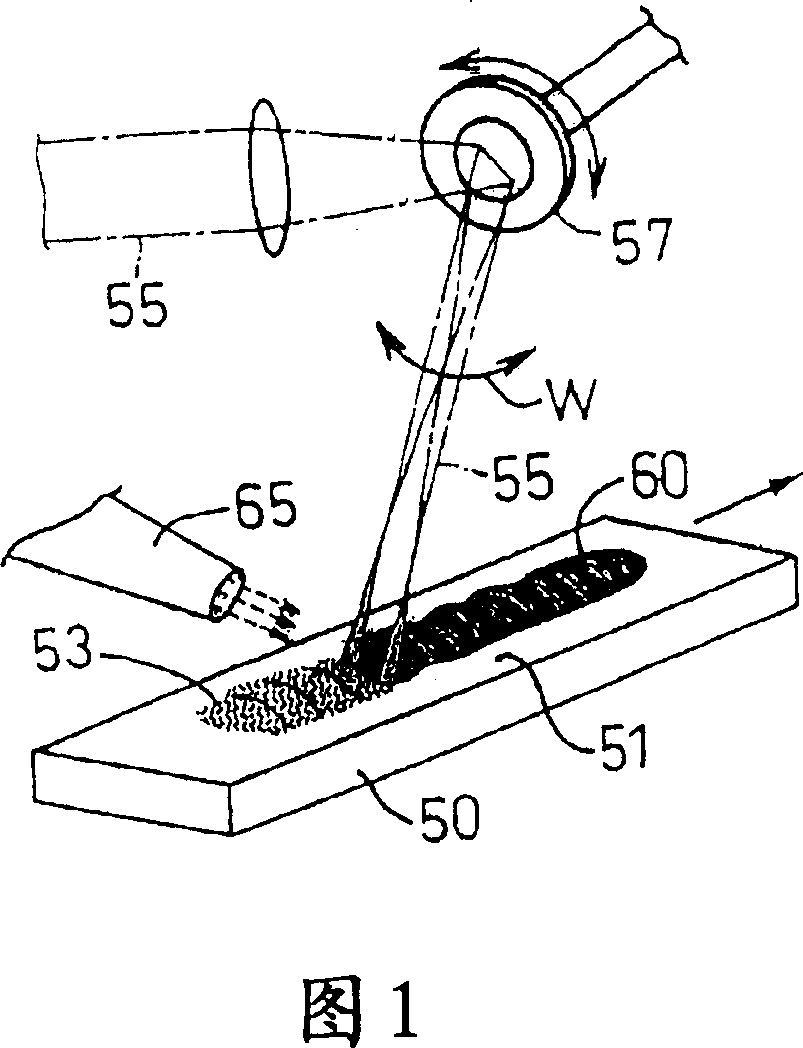

Method used

Image

Examples

example 1

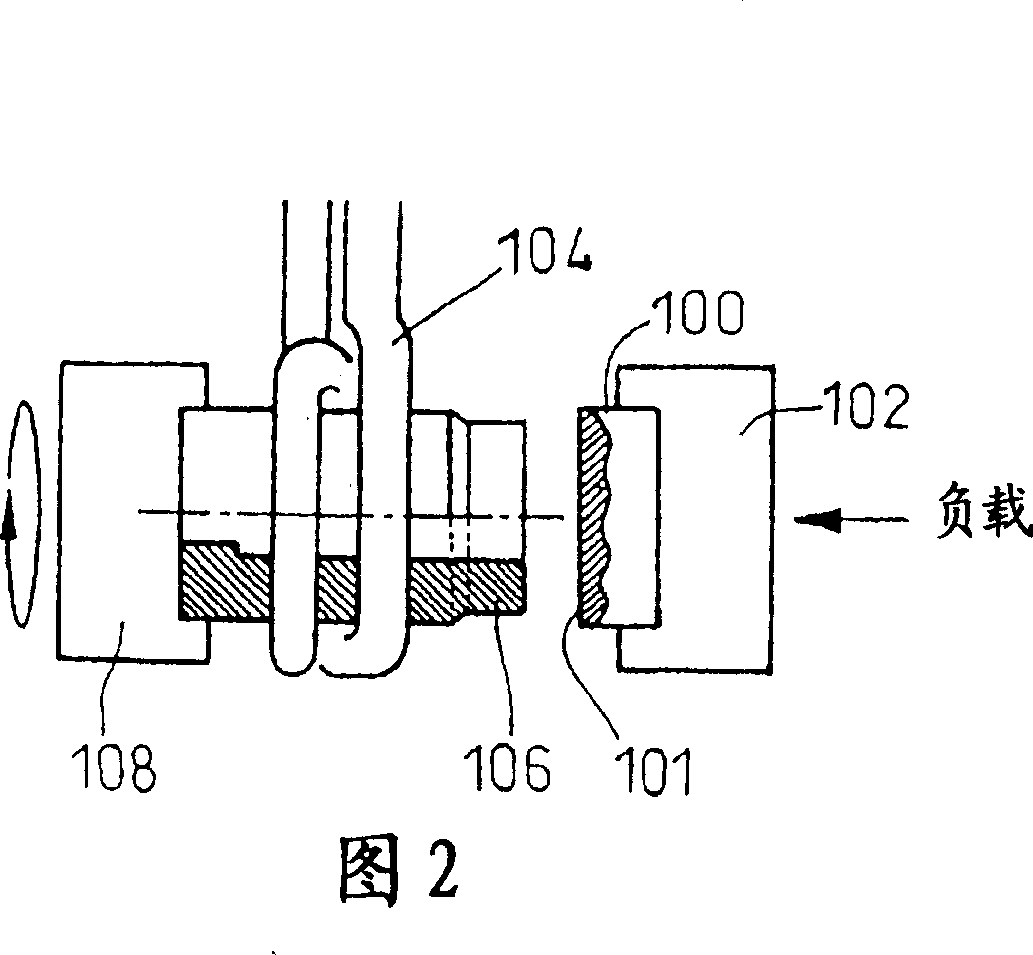

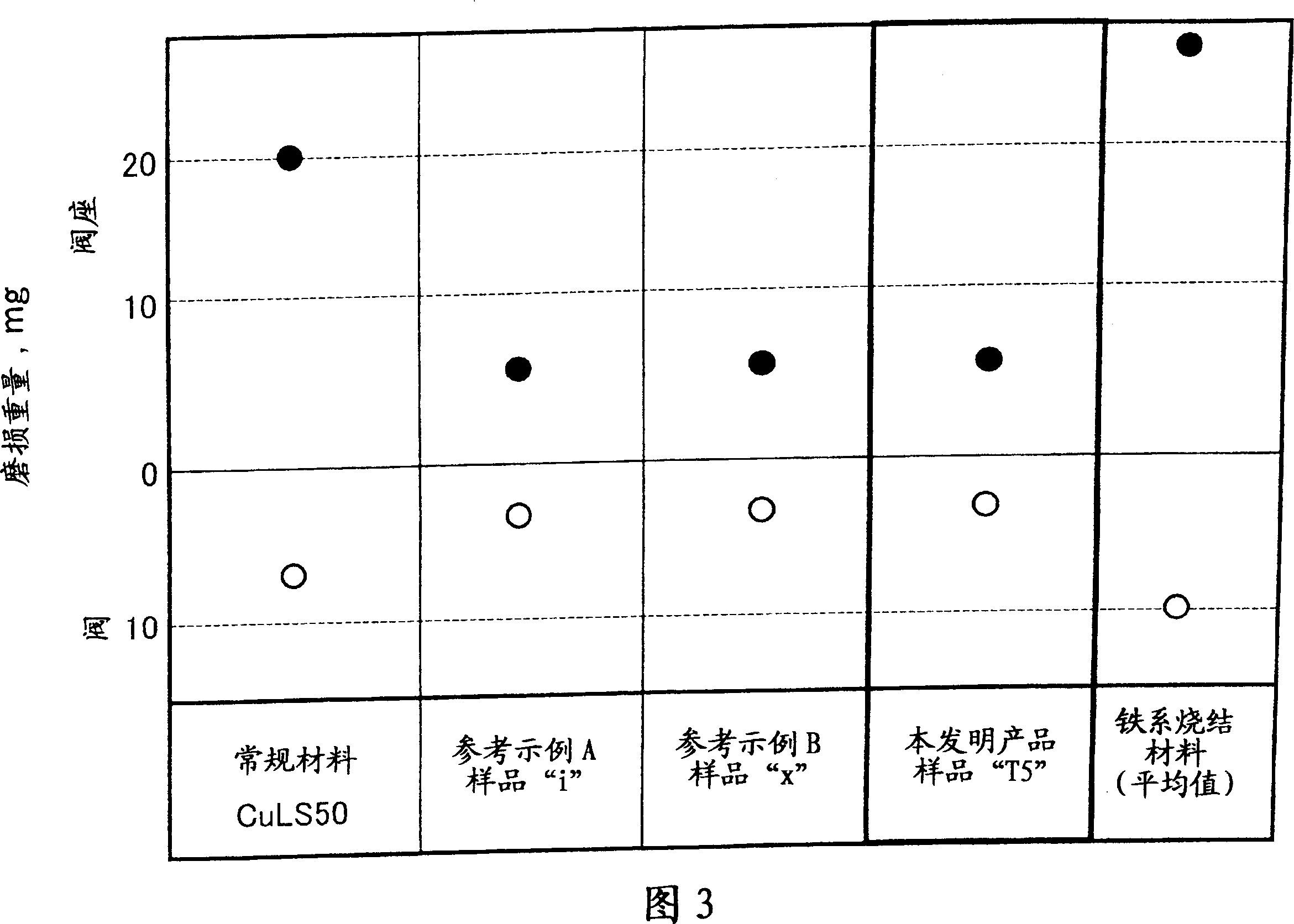

[0048] In the following, Example 1 of the present invention will be specifically described with reference to examples. Table 1 lists the compositions (analyzed compositions) of the samples ("T" series, "T" meaning containing titanium) of the surfacing wear-resistant copper-based alloy of the present invention used in this example. The composition of this assay is generally consistent with that of the batch. As listed in Table 1, the composition of Example 1 does not contain cobalt, iron, and molybdenum as positive elements, but contains titanium, and is set to a composition containing the following components by weight %: Nickel: 5.0-20.0 %, silicon: 0.5-5.0%, manganese: 3.0-30.0% and titanium: 3.0-30.0%, and the balance: copper. It should be noted that the sample "i", sample "a", sample "c", sample "e", sample "g" and sample "x" listed in Table 1 are different from the composition range of claim 1, And is designated as a reference sample.

[0049] Each of the above-mention...

example 2

[0061] Next, Example 2 of the present invention will be specifically described. In this example, too, the build-up layer was basically formed under conditions similar to Example 1. Table 2 lists the composition of the samples ("H" series, "H" means containing hafnium) of the surfacing wear-resistant copper-based alloy used in this example. As shown in Table 2, the composition of Example 2 does not actively contain cobalt, iron, and molybdenum, but contains hafnium, and is set into a composition including the following components by weight %: Nickel: 5.0-20.0%, Silicon: 0.5-5.0%, manganese: 3.0-30.0%, hafnium: 3.0-30.0%, and balance: copper.

[0062] When the weld overlay formed from each sample was examined, hard particles having a hard phase were dispersed in the matrix of the overlay. When the surfacing wear-resistant copper-based alloy is taken as 100%, the volume ratio of hard particles in the surfacing wear-resistant copper-based alloy is in the range of about 5-60% of ...

example 3

[0066] Next, Example 3 of the present invention will be specifically described. In this example, too, the build-up layer was basically formed under conditions similar to Example 1. Table 3 shows the composition of the samples ("Z" series, "Z" means containing zirconium) of the overlay wear-resistant copper-based alloy used in this example. As shown in Table 3, the composition of Example 3 does not actively contain cobalt, iron, and molybdenum, but contains zirconium, and is set within a composition including the following components by weight %: nickel: 5.0-20.0%, silicon: 0.5-5.0%, manganese: 3.0-30.0%, zirconium: 3.0-30.0%, and balance: copper.

[0067] As shown in Table 3, when examining the crack occurrence rate, the crack occurrence rate of the overlay layer formed by the sample of Example 3 was low and was 0%. Even when the zirconium content was changed, the crack occurrence rate was 0%. When considering the wear weight, the wear weight of the overlay layer formed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com