Substrate suction device and semiconductor processing equipment

A technology for sucking device and substrate, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as substrate crushing and large substrate deformation, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

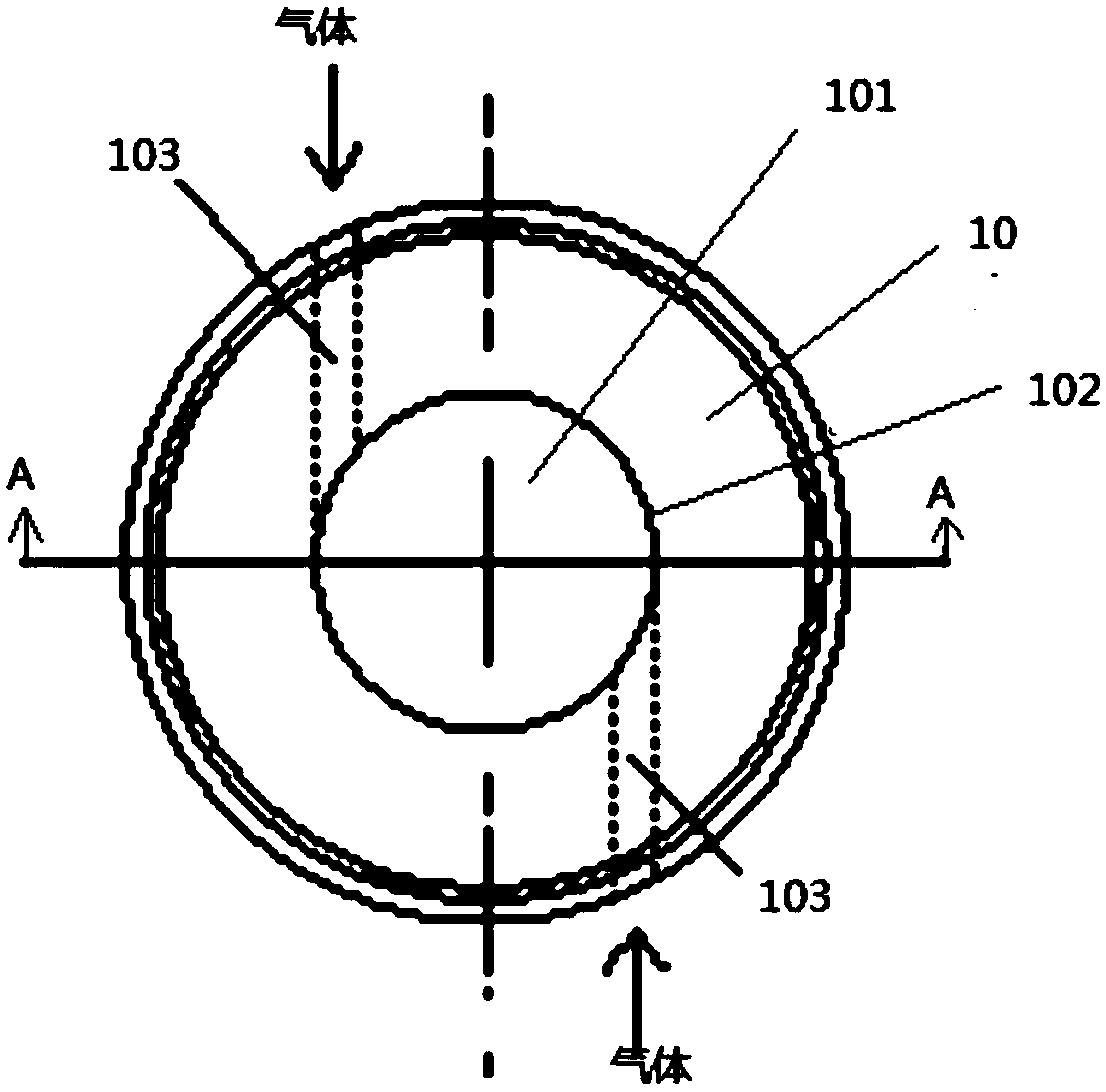

[0029] Figure 3a A top view of the substrate suction device provided in Embodiment 1 of the present invention; Figure 3b A cross-sectional view of the substrate pick-up device provided in Embodiment 1 of the present invention; Figure 4 for Figure 3a and Figure 3b Schematic diagram of the substrate pick-up setup shown; see also Figure 3a , 3b And 4, the substrate suction device provided by the embodiment of the present invention includes: a body 10; a cavity 101 with an opening 102 at the lower end is formed in the body 10; an air inlet 103 communicating with the cavity 101 is provided at the upper end of the body 10 , the inlet hole 103 is used to be connected with the compressed gas source, so that the compressed gas provided by the compressed gas source enters the cavity 101 from the inlet hole 103 to form a vortex air flow and is discharged from the opening 102 (the gas is in a spiral shape under the action of air pressure. shape gradually moves downward, and fin...

Embodiment 2

[0033] Compared with the substrate suction device provided in the embodiment 1 of the present invention, the substrate suction device provided in the embodiment of the present invention can be found in Figure 5-7 , also including the main body 10, since the main body 10 has been described in detail in the above-mentioned embodiment 1, it will not be repeated here.

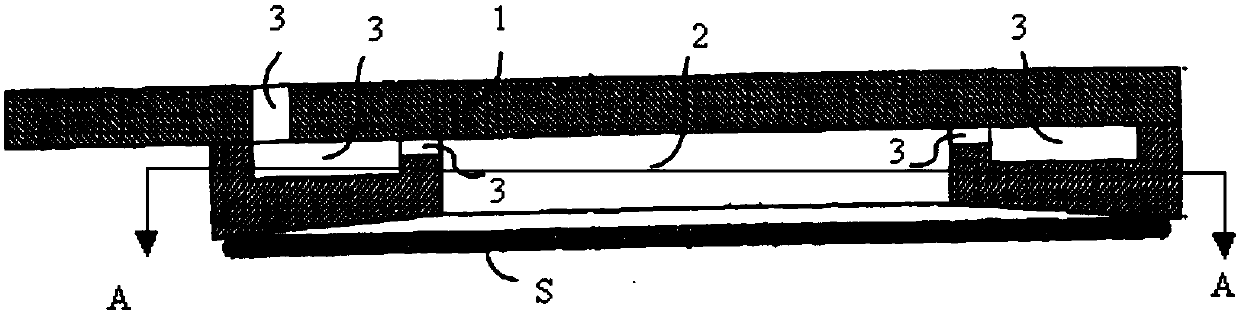

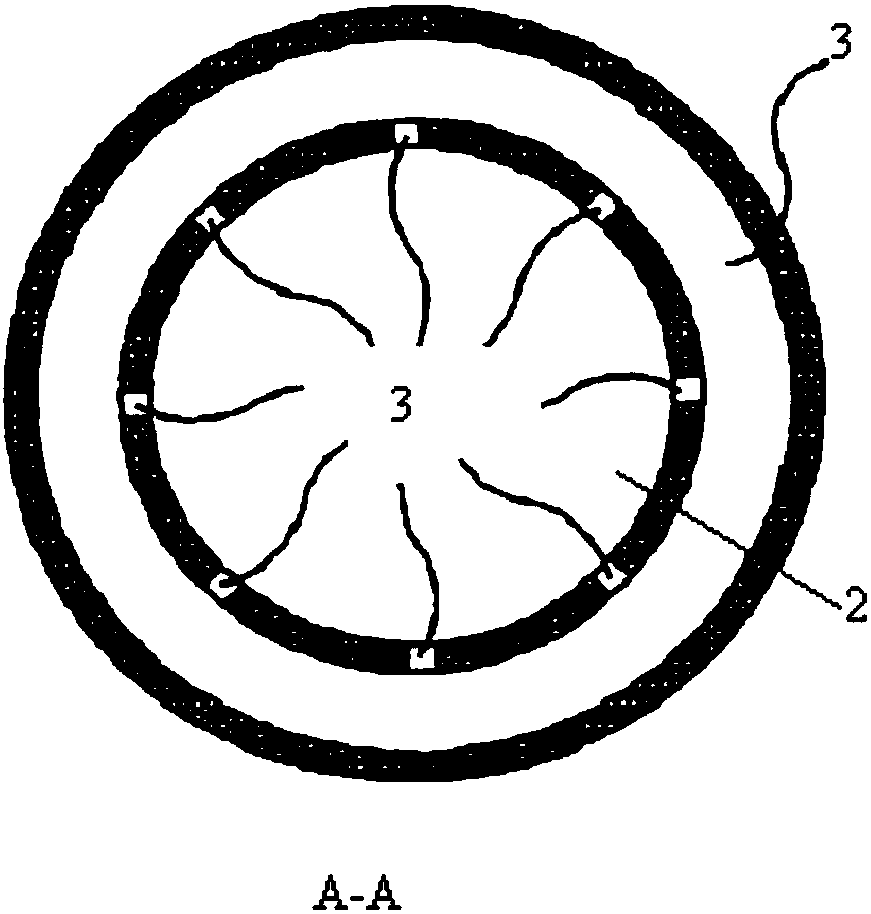

[0034] Only the differences between this embodiment and the above-mentioned Embodiment 1 will be described below. Specifically, the number of bodies 10 in the substrate pick-up device provided in Embodiment 2 is multiple; the multiple bodies 10 correspond to different regions of the substrate S, so as to absorb and fix different regions of the substrate S correspondingly. In this way, The problem of unstable adsorption caused by the limited adsorption force of the single body 10 can be avoided. The unstable adsorption includes: the orientation of the substrate S cannot be controlled when the substrate S rotates wi...

Embodiment 3

[0047] An embodiment of the present invention provides a semiconductor processing device, including: a substrate pick-up device and a transfer device; the substrate pick-up device adopts the substrate pick-up device provided in Embodiments 1 and 2 above to fix the substrate; the transfer device is used to control The substrate pick-up moves to indirectly transport the substrates.

[0048] The semiconductor processing equipment provided by the embodiment of the present invention adopts the substrate suction device provided by the above-mentioned embodiments 1 and 2, so problems such as damage and deformation to the surface of the substrate during substrate transfer can be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com