Co-curing composite material thin-wall fuel tank with omega-shaped frame body and forming method

A composite material and molding method technology, which is applied in the field of co-cured composite material thin-walled fuel tanks and molding, can solve the problems of insufficient load-bearing capacity at the connection position of the hanger of the composite fuel tank, and achieve light weight, strong load-bearing capacity of the hanger, and The effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The technical problem to be solved in this embodiment is that in order to reduce the weight of the aircraft, a composite material fuel tank is designed and manufactured, which greatly reduces the weight of the fuel tank. The structural strength has very high requirements, and the existing composite material fuel tank has insufficient structural stability, especially the insufficient load-bearing capacity at the connection position of the pylon of the fuel tank.

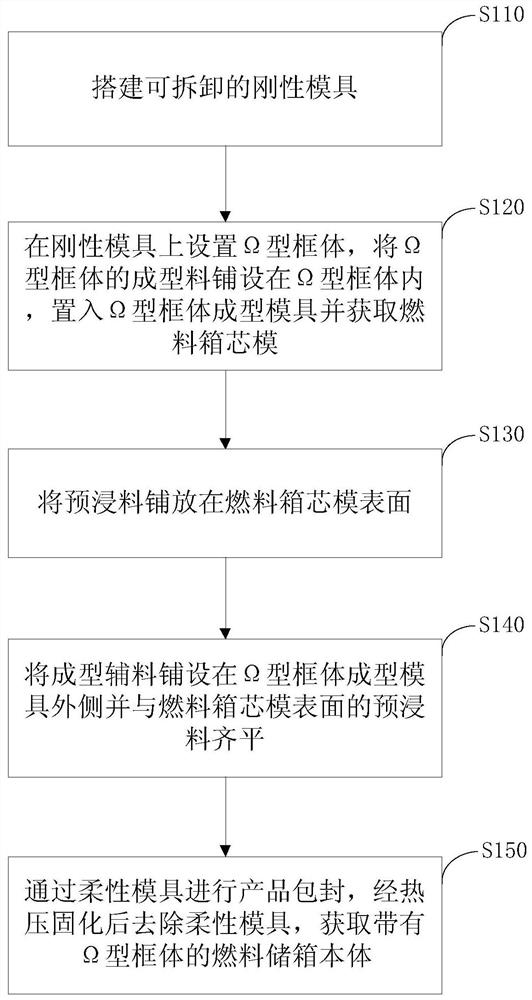

[0044] In order to solve the above technical problems, such as figure 1 As shown, the present embodiment provides a molding method of a co-cured composite material thin-walled fuel tank with an Ω-shaped frame, comprising the following steps:

[0045] S110: building a detachable rigid mold;

[0046] S120: setting the Ω-shaped frame body on the rigid mold, laying the molding material of the Ω-shaped frame body in the Ω-shaped frame body, inserting the Ω-shaped frame body forming mold 30 and obtaining the fuel ta...

Embodiment 2

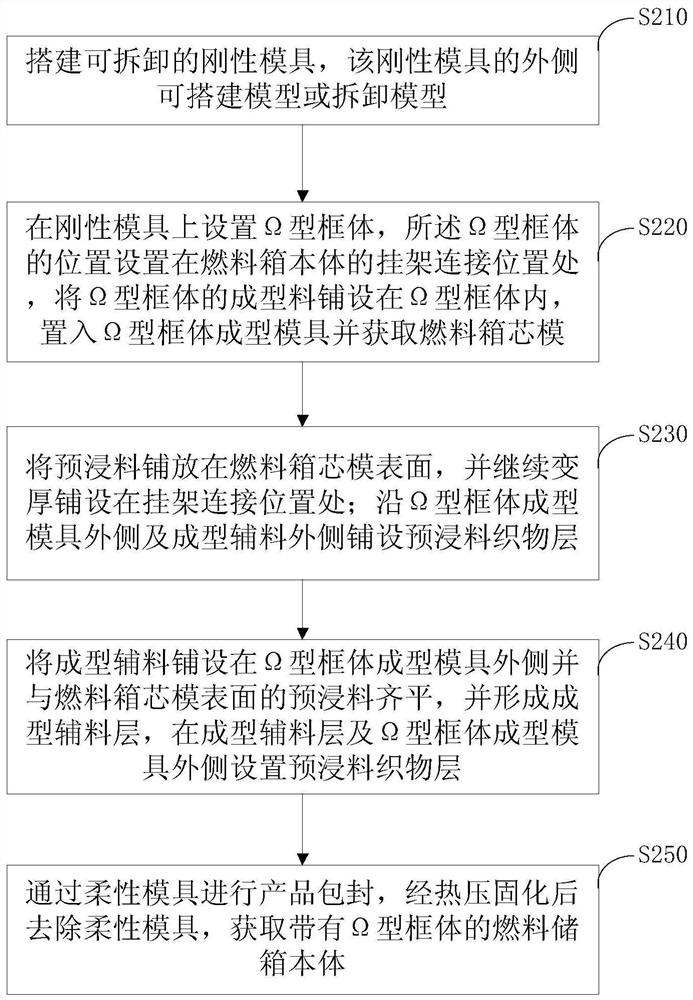

[0052] This embodiment provides a molding method of a co-cured composite material thin-walled fuel tank with an Ω-shaped frame, comprising the following steps:

[0053] S210: Build a detachable rigid mold, and the outer side of the rigid mold can be built or disassembled;

[0054]S220: Set the Ω-shaped frame on the rigid mold, the position of the Ω-shaped frame is set at the connection position of the hanger of the fuel tank body, the molding material of the Ω-shaped frame is laid in the Ω-shaped frame, and the Ω-shaped frame is inserted into the Ω-shaped frame. Type frame forming mold 30 and obtain fuel tank mandrel;

[0055] S230: Lay the prepreg on the surface of the fuel tank mandrel, and continue to thicken and lay it at the connection position of the hanger; lay the prepreg fabric layer 20 along the outside of the Ω-shaped frame forming mold 30 and the outside of the molding auxiliary material, the said The prepreg fabric layer 20 includes at least two layers, and the w...

Embodiment 3

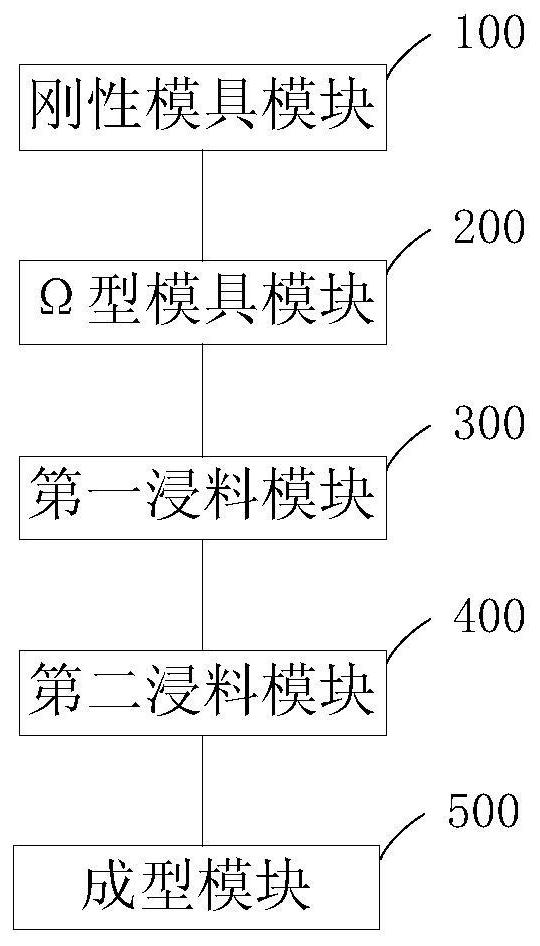

[0064] The present invention also provides a thin-walled fuel tank of co-cured composite material with an Ω-shaped frame, such as image 3 shown, including:

[0065] The rigid mold module 100 is used to build a detachable rigid mold;

[0066] The Ω-shaped mold module 200 is used to set the Ω-shaped frame on the rigid mold, lay the molding material of the Ω-shaped frame in the Ω-shaped frame, insert the Ω-shaped frame forming mold 30 and obtain the fuel tank mandrel;

[0067] The first impregnation module 300 is used to lay the prepreg on the surface of the fuel tank mandrel;

[0068] The second impregnating material module 400 is used to lay the molding auxiliary material on the outside of the Ω-shaped frame forming mold 30 and be flush with the prepreg on the surface of the fuel tank mandrel;

[0069] The forming module 500 is used for encapsulating the product through a flexible mold, and removing the flexible mold after hot pressing and curing to obtain a fuel tank body w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com