High-speed bearing retainer

A high-speed bearing and cage technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of uneven distribution, unstable cage operation, accumulation of internal grease on one side, etc., to enhance lubrication and heat dissipation. effect, guaranteed strength, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

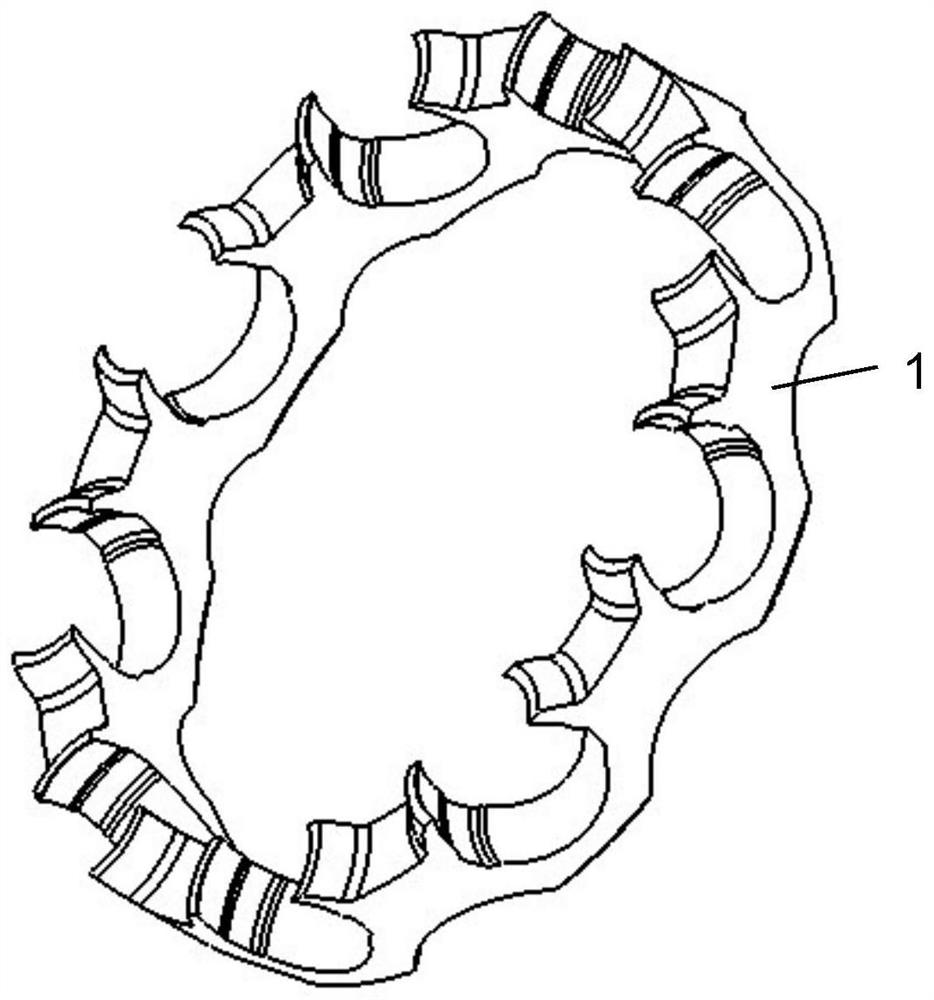

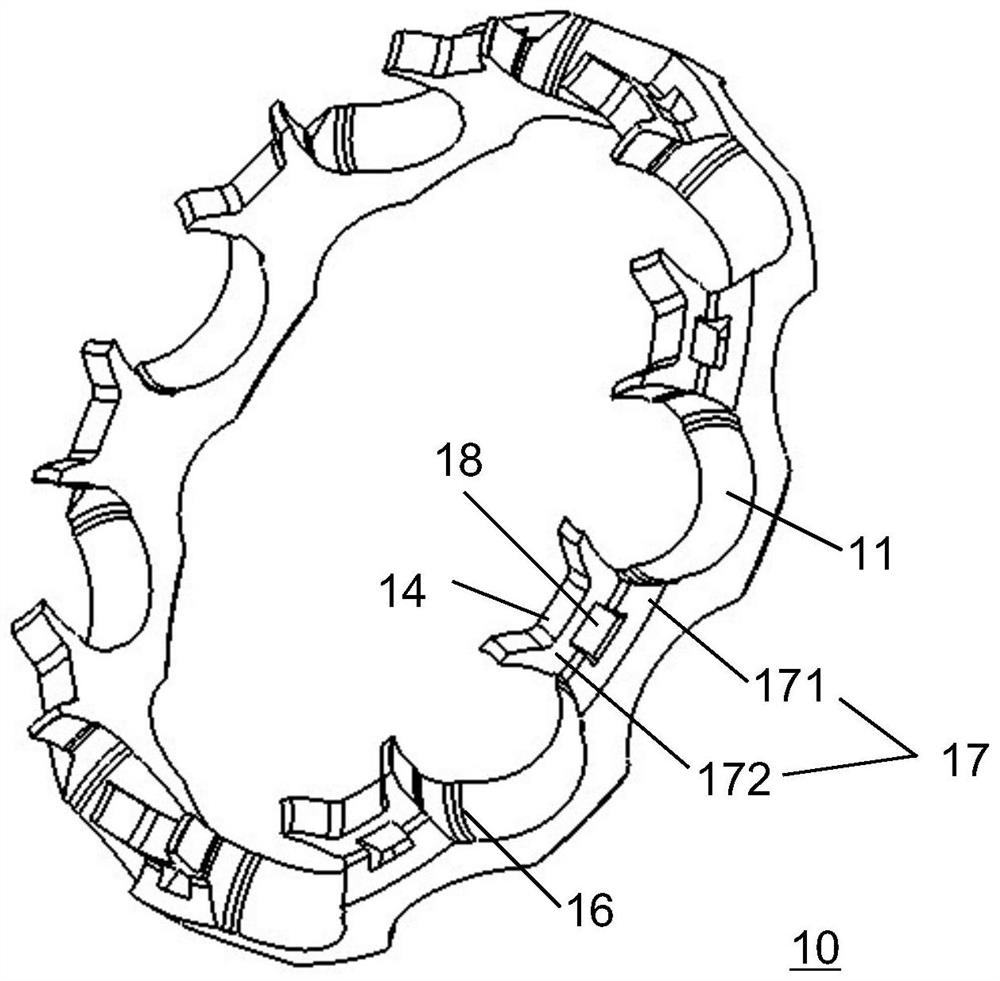

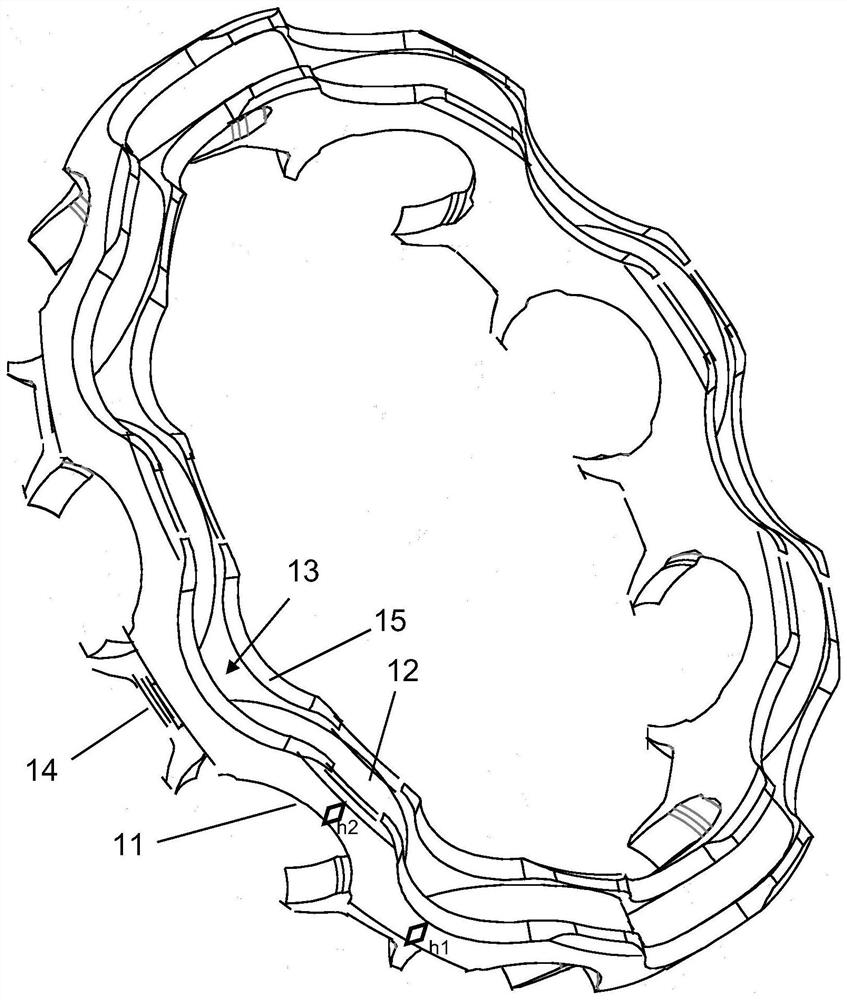

[0020] The high-speed bearing cage of the present invention is as Figure 2 to Figure 5 As shown, it is the same as the prior art in that it also includes an annular frame body 10, a plurality of pockets 11 evenly arranged on the upper end of the frame body 10, an annular groove 12 arranged at the bottom of the frame body 10, and pocket holes 11. The upper end forms an open jaw, and the bottom of the connection part 14 between two adjacent pocket holes 11 is provided with an upwardly concave arc surface 15, and each connection part 14 is provided with a grease chamber 13, and the grease container The bottom opening of the chamber 13 is located in the ring groove 12, and the middle positions of the inner surfaces on both sides of the pocket hole 11 are radially provided with an oil groove 16. Different from the prior art, the connecting portion 14 between two adjacent pocket holes 11 is designed as upper and lower parts. A cut-off step is formed, and the step has an oil guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com