Rhombic cable ladder applied to wind power generation system

A technology for wind power generation systems and cable ladders, applied in electrical components and other directions, can solve problems such as insufficient anti-corrosion performance, protective sheath wear, transmission loss, etc., and achieve the effect of improving anti-corrosion, prolonging service life, and improving protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

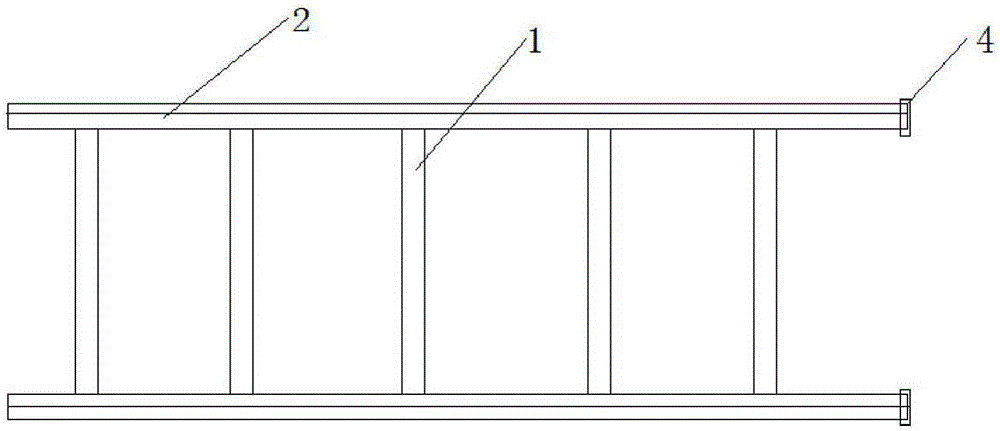

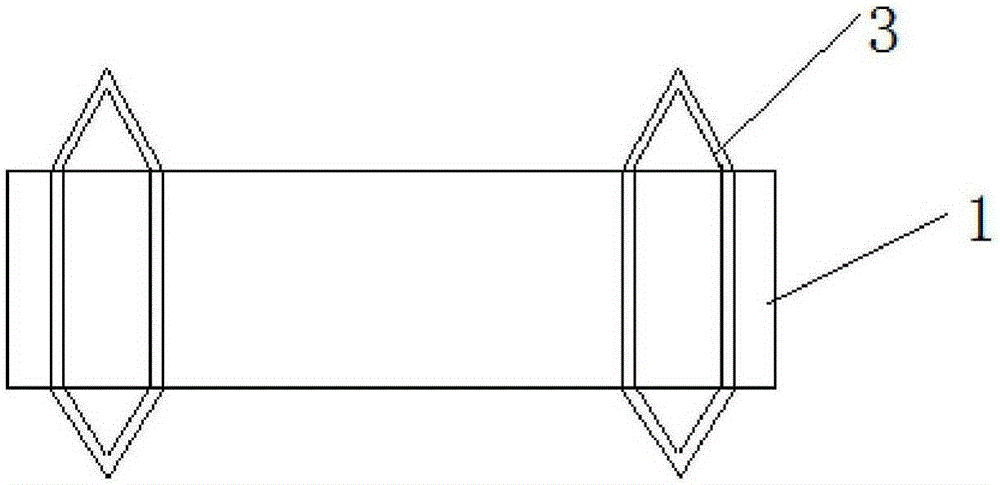

[0035] Such as figure 1 with figure 2 A diamond-shaped cable ladder applied to a wind power generation system is shown, comprising: a circular pipe 1 and a diamond-shaped pipe 2, the circular pipe 1 passing between the two diamond-shaped pipes 2, and the relative positions of the two diamond-shaped pipes 2 Installing hole 3 is arranged on it, and described rhombus tube 2 adopts rhombic hexagonal tube, and there is no fast mouth on it, and its bottom is provided with rubber sleeve 4, and described rubber sleeve 4 matches with rhombus tube 2.

[0036] The installation hole 3 described in this embodiment is diamond-shaped, and there is no quick opening on the installation hole 3 , and the installation hole 3 matches the round pipe 1 .

[0037] The circular pipe 1 and the diamond-shaped pipe 2 described in this embodiment are provided with a protective film, the protective film is a hot-dip galvanized film, and the film thickness of the hot-dip galvanized film is 65-100 microns....

Embodiment 2

[0039] The production process of a diamond-shaped cable ladder applied to a wind power generation system described in this embodiment is based on the structure of a diamond-shaped cable ladder applied to a wind power generation system in Embodiment 1.

[0040] A kind of production process of the diamond-shaped cable ladder applied to the wind power generation system described in this embodiment, the specific production process steps are as follows:

[0041] (1): First, according to the customer's order requirements, prepare the required round pipe 1 and rhombic pipe 2 and the equipment required for production and processing according to the size requirements;

[0042] (2): After the required materials and equipment are ready, burr the ends of the round tube 1 and rhombic tube 2;

[0043] (3): After the end burrs of the round tube 1 and the rhomboid tube 2 are removed, punch holes on the rhomboid tube 2;

[0044] (4): During the punching process, ensure the punching size and t...

Embodiment 3

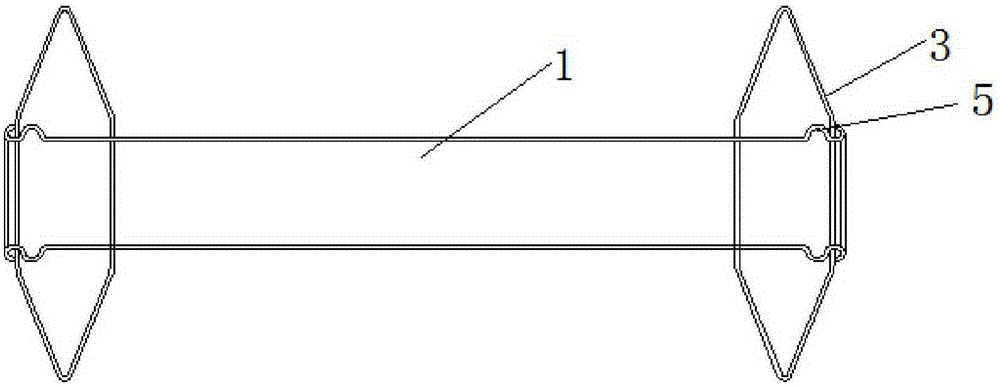

[0052] Such as figure 1 with image 3A diamond-shaped cable ladder applied to a wind power generation system is shown, comprising: a circular pipe 1 and a diamond-shaped pipe 2, the circular pipe 1 passing between the two diamond-shaped pipes 2, and the relative positions of the two diamond-shaped pipes 2 Installing hole 3 is arranged on it, and described rhombus tube 2 adopts rhombic hexagonal tube, and there is no fast mouth on it, and its bottom is provided with rubber sleeve 4, and described rubber sleeve 4 matches with rhombus tube 2.

[0053] The two ends of the round tube 1 described in this embodiment are provided with tensioning blocks 5, and the edges of the tensioning blocks 5 are in the shape of a smooth arc.

[0054] The installation hole 3 described in this embodiment is diamond-shaped, and there is no quick opening on the installation hole 3 , and the installation hole 3 matches the round pipe 1 .

[0055] The circular pipe 1 and the diamond-shaped pipe 2 desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com