Electric reactor based on hollow wire wrap and manufacturing method of electric reactor

A manufacturing method and technology of hollow wire, applied in the direction of inductor/transformer/magnet manufacturing, coil manufacturing, inductors, etc., can solve the problems of reducing product performance, prolonging product manufacturing time, increasing labor intensity of employees, etc., to avoid iron core cakes Deformation, reducing labor intensity, and beneficial to heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

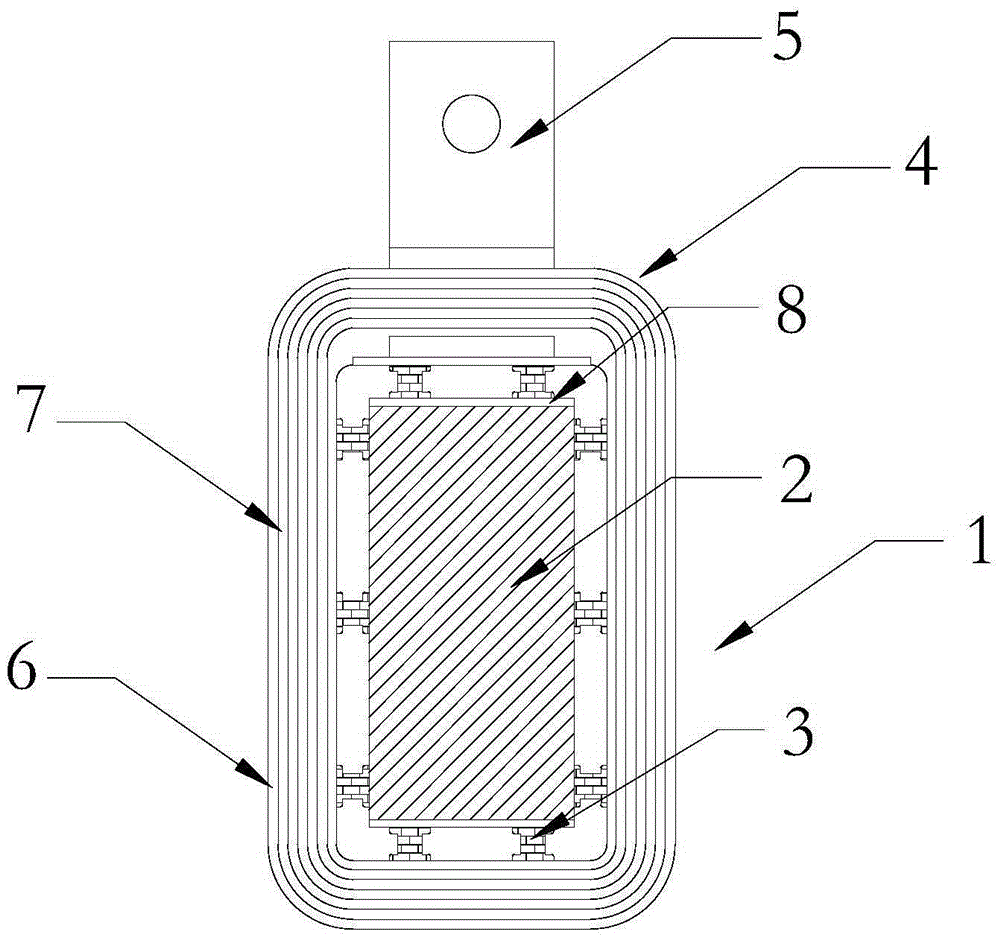

[0039] Embodiment 1. A schematic structural diagram of a reactor based on a hollow wire package, the following will be combined with the attached figure 1 A reactor based on the hollow wire package of the present invention is introduced in detail.

[0040] Such as figure 1 As shown, a reactor based on a hollow wire pack includes a hollow wire pack 1 and a core cake 2, the hollow wire pack 1 is sleeved on the core cake 2, and the hollow wire pack 1 and the core cake 2 There is an annular gap between the core cakes 2, and a plurality of I-shaped stays 3 are arranged around the outer periphery of the core cake 2 in the annular gap, and the hollow wire package 1 and the core cake 2 pass through multiple The I-shaped stay 3 is fastened and set.

[0041] In this embodiment, the hollow wire package 1 includes a coil body 4 and a connecting row 5 , and the connecting row 5 is vertically welded on one side of the coil body 4 . Through the above method, it is convenient to wind the c...

Embodiment 2

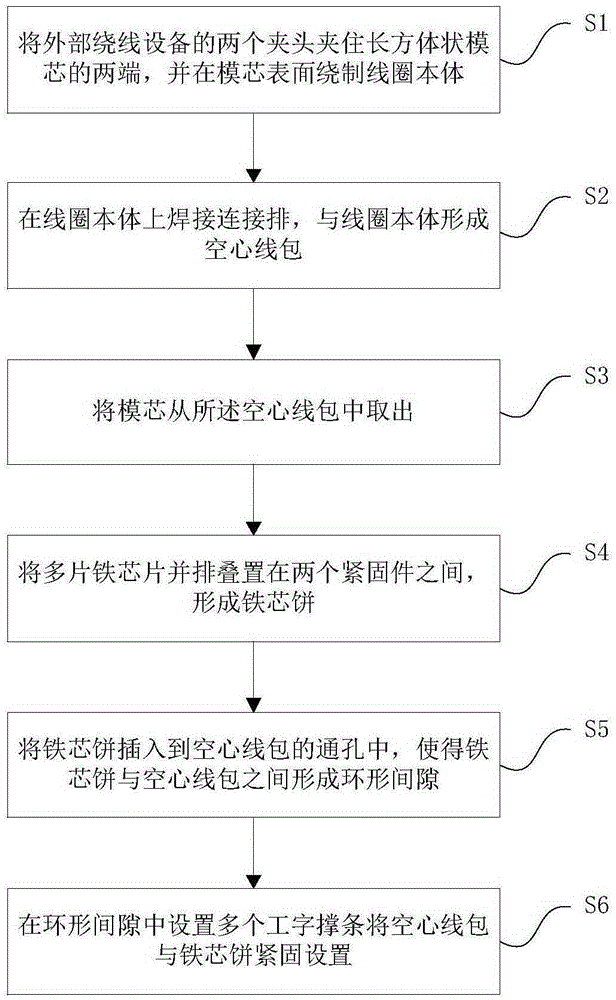

[0050] Embodiment 2, a method of manufacturing a reactor based on a hollow wire package, which will be combined below figure 2 A method for manufacturing a reactor based on a hollow wire wrap in the present invention is introduced in detail.

[0051] Such as figure 2 As shown, a method for manufacturing a reactor based on a hollow wire package includes the following steps:

[0052] Step 1: Clamp the two ends of the cuboid mold core with the two chucks of the external winding device, and wind the coil body 4 on the surface of the mold core;

[0053] Step 2: Weld the connecting row 5 on the coil body 4, and the connecting row 5 and the coil body 4 together form a hollow wire package 1;

[0054] Step 3: taking out the mold core from the hollow wire package 1;

[0055] Step 4: Stack multiple iron chips side by side between two fasteners 8 to form an iron core cake 2;

[0056] Step 5: Insert the core cake 2 into the through hole of the hollow wire package 1, so that an annula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com