Machining method of flexible stress isolation thin ring for precise optical-mechanical system

A technology of stress isolation and processing method, applied in the field of flexible stress isolation thin ring processing, can solve the problems of lens deformation, large clamping deformation, distortion of thin-walled ring parts, etc., and achieve the effect of improving processing efficiency and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

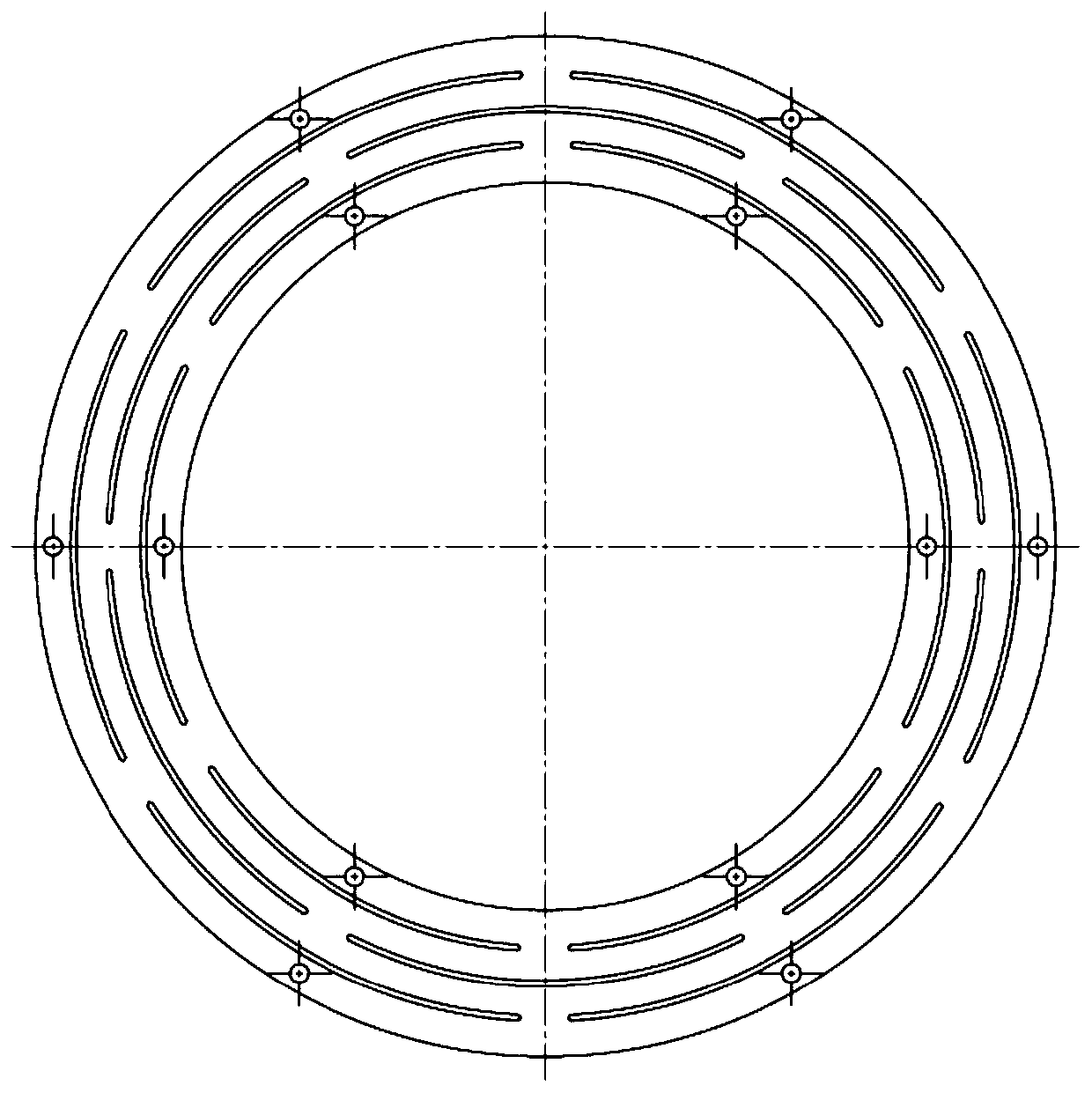

[0034] The size of a certain model is 1mm wall thickness, 200mm inner diameter and 250mm outer diameter.

[0035] The following takes the processing of this model product as an example to illustrate the specific processing technology of the flexible stress isolation thin ring of the present invention.

[0036] The first step: rough car shape and inner diameter;

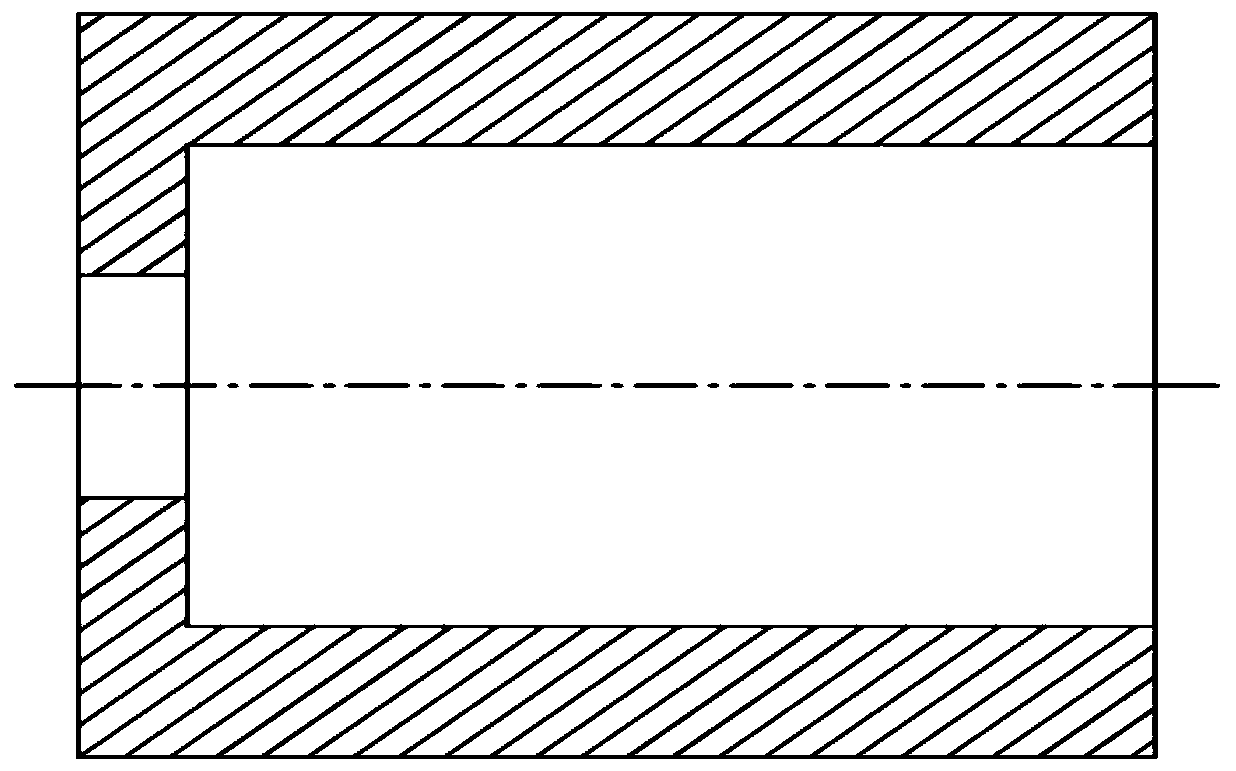

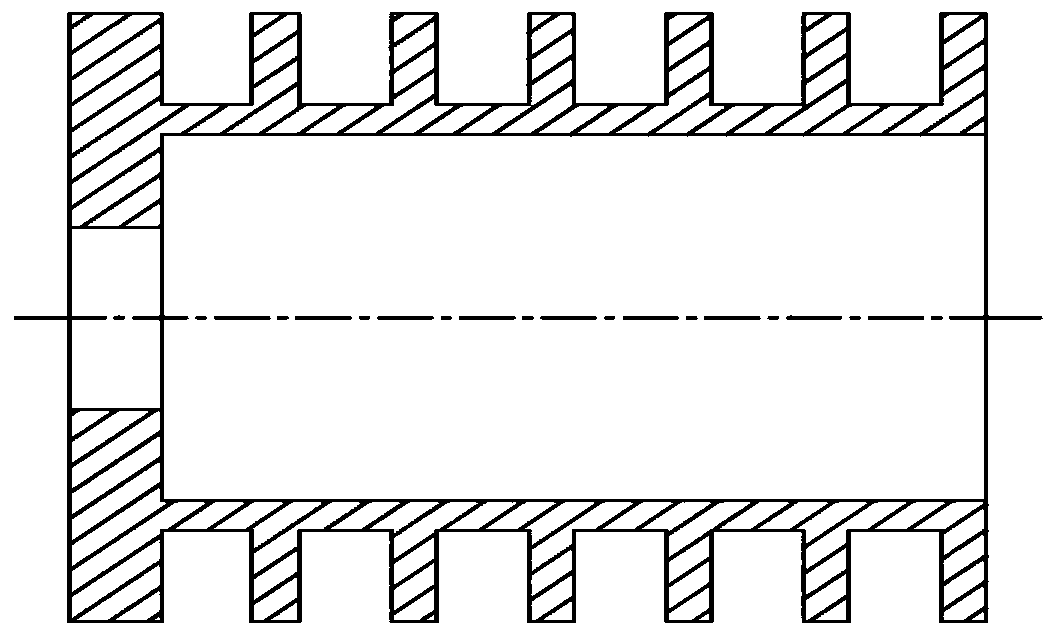

[0037] Rough turning the blank into figure 1 In the cylindrical workpiece shown, the blank is spring steel, the axial length of the workpiece is the sum allowance of the target axial thickness of a plurality of thin rings, the machining allowance is 3mm, the inner diameter and outer diameter of the workpiece The diameter is left with a margin, the outer diameter is 2mm, and the inner diameter is 5mm. , And one end of the workpiece has a chuck part whose radial thickness is greater than that of other positions, and the length of the chuck part is 20mm. The workpiece after rough turning is subjected to the first heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com