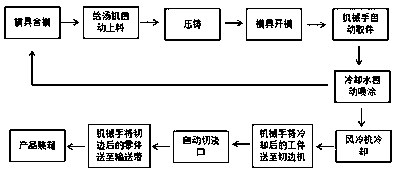

Robot pressure casting island automatic circulating device and process

An automatic circulation and robot technology, applied in manufacturing tools and other manufacturing equipment/tools, etc., can solve problems such as high product rejection rate and poor product quality consistency, reduce production costs, stabilize product quality, and prevent mold temperature from being too high Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

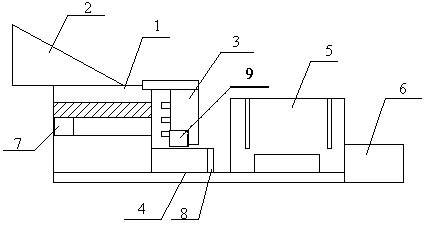

[0019] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0020] Such as Figure 1 to Figure 2 As shown, an automatic circulation device for a robot die-casting island, which includes a die-casting machine 1, a soup feeder 2, a spraying robot 3, a pick-up robot 4, an air cooler 9, an edge trimmer 5, and a casting conveyor 6, and the soup feeder 2 is installed above the die-casting machine 1, the spraying robot 3 is connected with the die-casting machine 1, the pick-up robot 4 is installed under the spraying robot 3 and connected with the die-casting machine 1, the air cooler 9 is installed under the spraying machine 3, and the trimming machine 5 It is installed on the right side of the spraying robot 3 and the pick-up robot 4, and the casting conveyor 6 is installed on the right side of the trimming machine 5.

[0021] The die-casting machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com