Exposure method and manufacturing method of semiconductor device

An exposure method and a technology to be exposed, which are applied in the field of photolithography and can solve the problems of affecting the inter-field magnification of overlay and increasing the error of overlay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

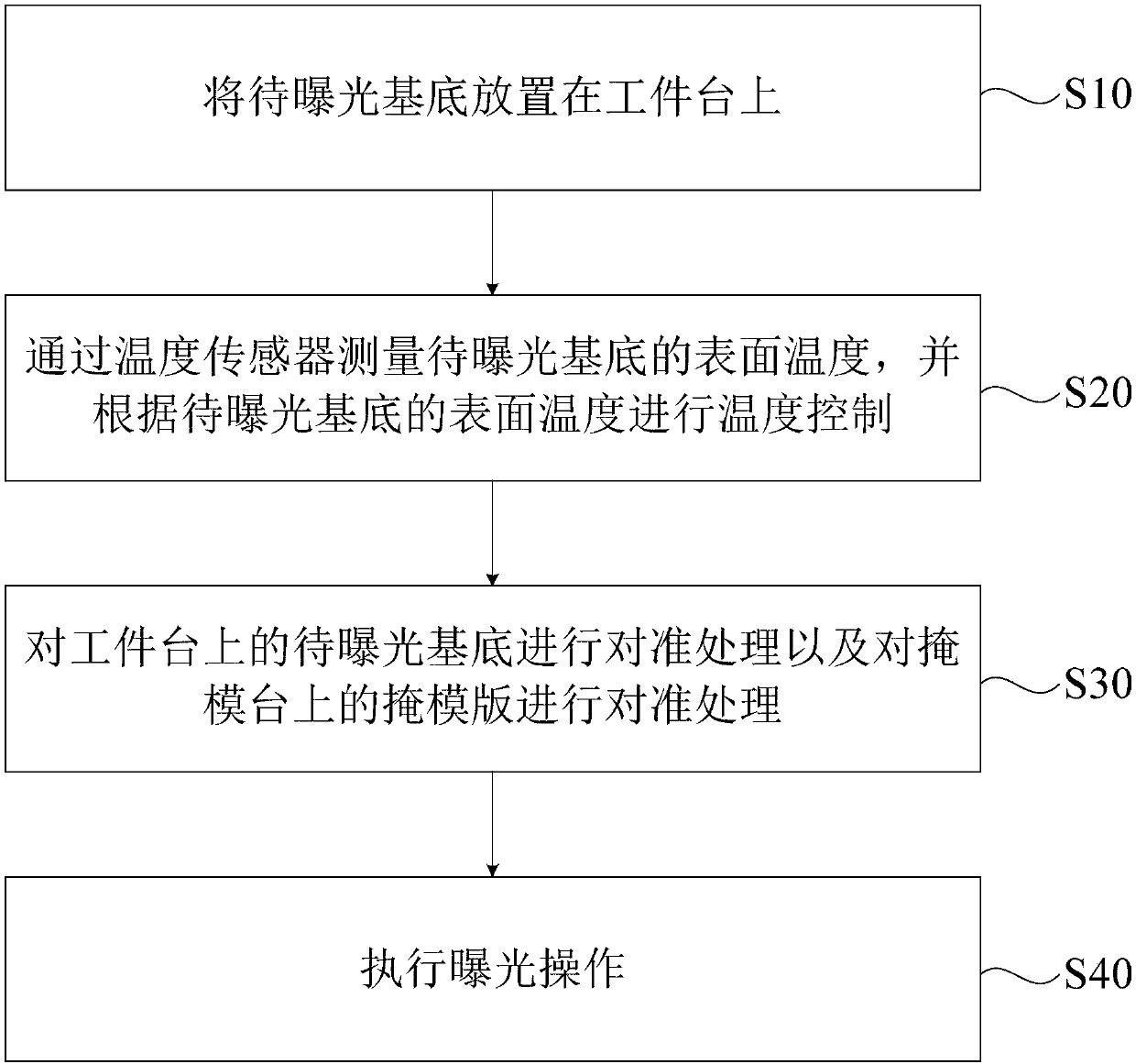

[0045] figure 1 It is a flow chart of an exposure method provided by Embodiment 1 of the present invention. see figure 1 , the exposure method provided by the embodiment of the present invention, comprising:

[0046] S10: placing the substrate to be exposed on the workpiece table.

[0047] It can be understood that the workpiece table can be moved. Generally, the workpiece table can be in two positions, one is the exposure position vertically corresponding to the mask plate, which is used for exposing the substrate to be exposed, and the other is the exposure position related to the temperature. The measurement position corresponding to the sensor is used for operations such as alignment of the substrate to be exposed.

[0048] The manipulator takes out the substrate to be exposed from the film library, and first places the substrate to be exposed on the pre-alignment table for pre-alignment. After the pre-alignment of the substrate to be exposed is completed, the substrate...

Embodiment 2

[0079] This embodiment may provide an optional example based on the foregoing embodiments. On the basis of the foregoing embodiments, the exposure method includes:

[0080] S10: placing the substrate to be exposed on the workpiece table.

[0081] S20: Measure the surface temperature of the substrate to be exposed by using a temperature sensor, and perform temperature control according to the surface temperature of the substrate to be exposed.

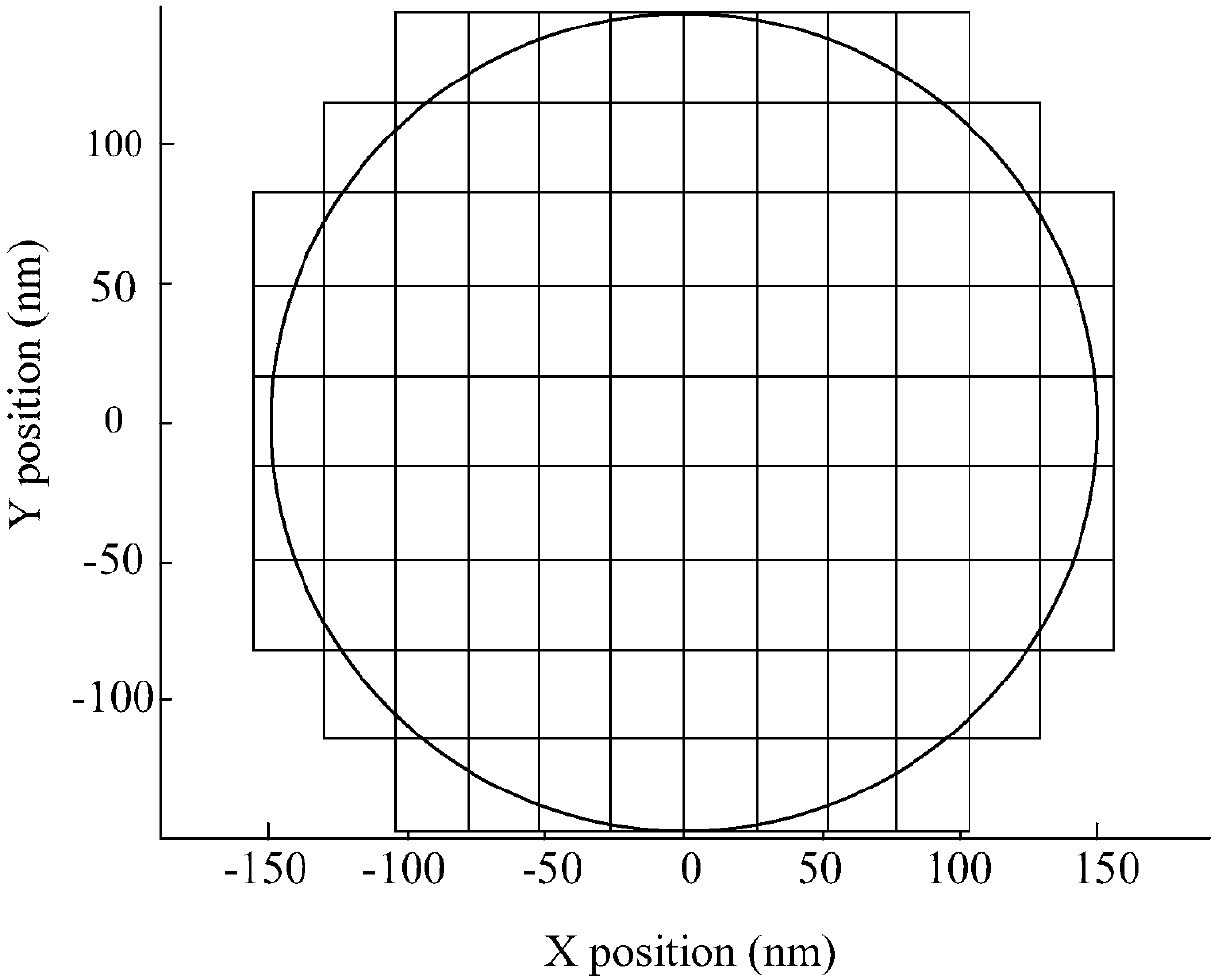

[0082] Wherein, there are many specific implementation methods for this step, and typical examples will be described in detail below, but this does not constitute a limitation to the present application. When the surface of the substrate to be exposed is divided into multiple temperature control fields, optionally, S20 includes:

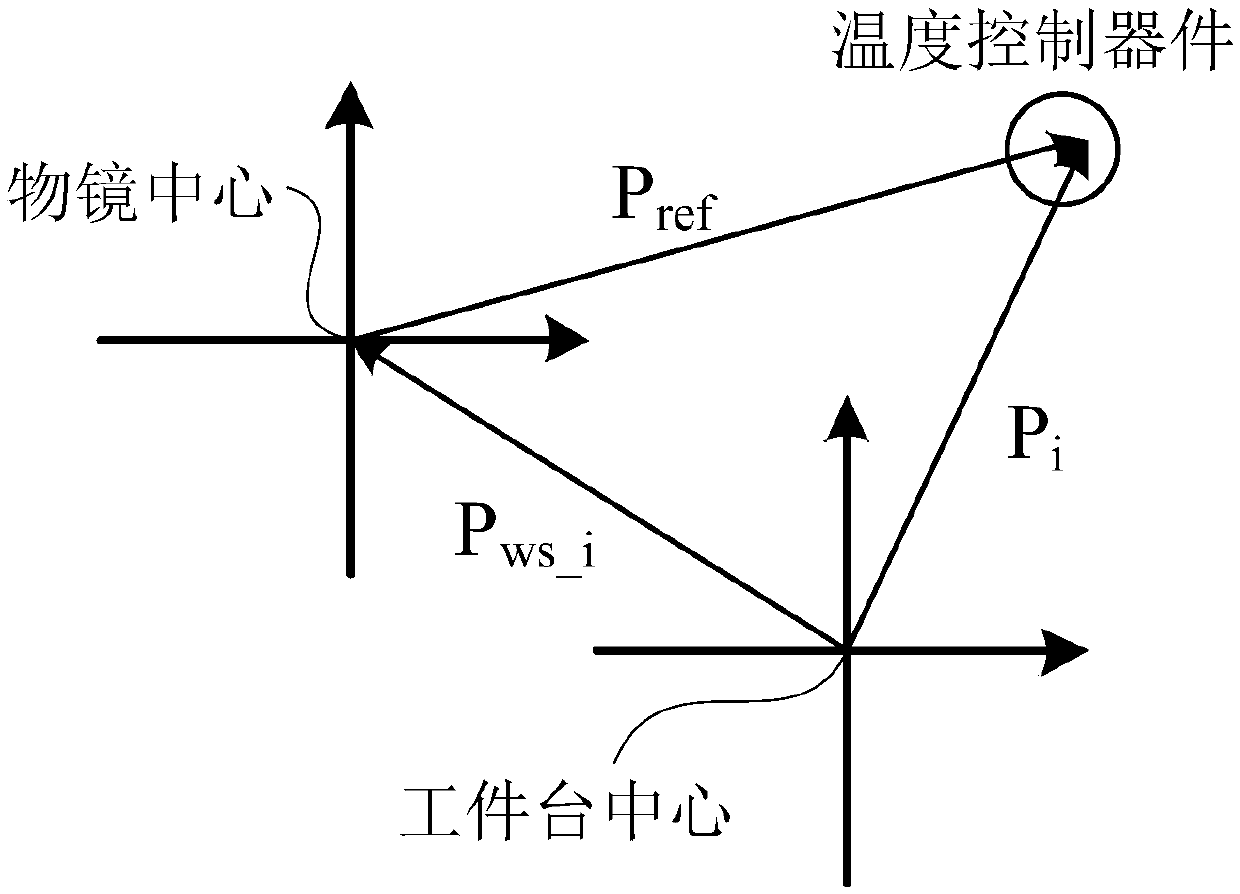

[0083] First, the surface temperature of the temperature control field of the substrate to be exposed is sequentially measured according to a first preset path, and the temperature control field of the tempe...

Embodiment 3

[0106] Embodiment 3 of the present invention provides a method for manufacturing a semiconductor device including the exposure method provided by the above embodiments.

[0107] In the manufacturing method of the semiconductor device, during the exposure process of the semiconductor device, the exposure method provided in the above-mentioned embodiments is used for exposure, and the substrate to be exposed is controlled between the alignment operation and the exposure operation by controlling the surface temperature of the substrate to be exposed. The temperature difference is reduced and the time difference is shortened, which avoids problems such as deformation of the substrate to be exposed caused by too long time difference and large temperature difference, and improves the accuracy of exposure of the substrate to be exposed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com