Embryo forming and slicing equipment for food processing and use method

A food processing and slicing technology, applied in metal processing, manufacturing tools, presses, etc., can solve the problems of single cooling forming function, damage, inconvenient use, etc., and achieve the effect of convenient continuous processing and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

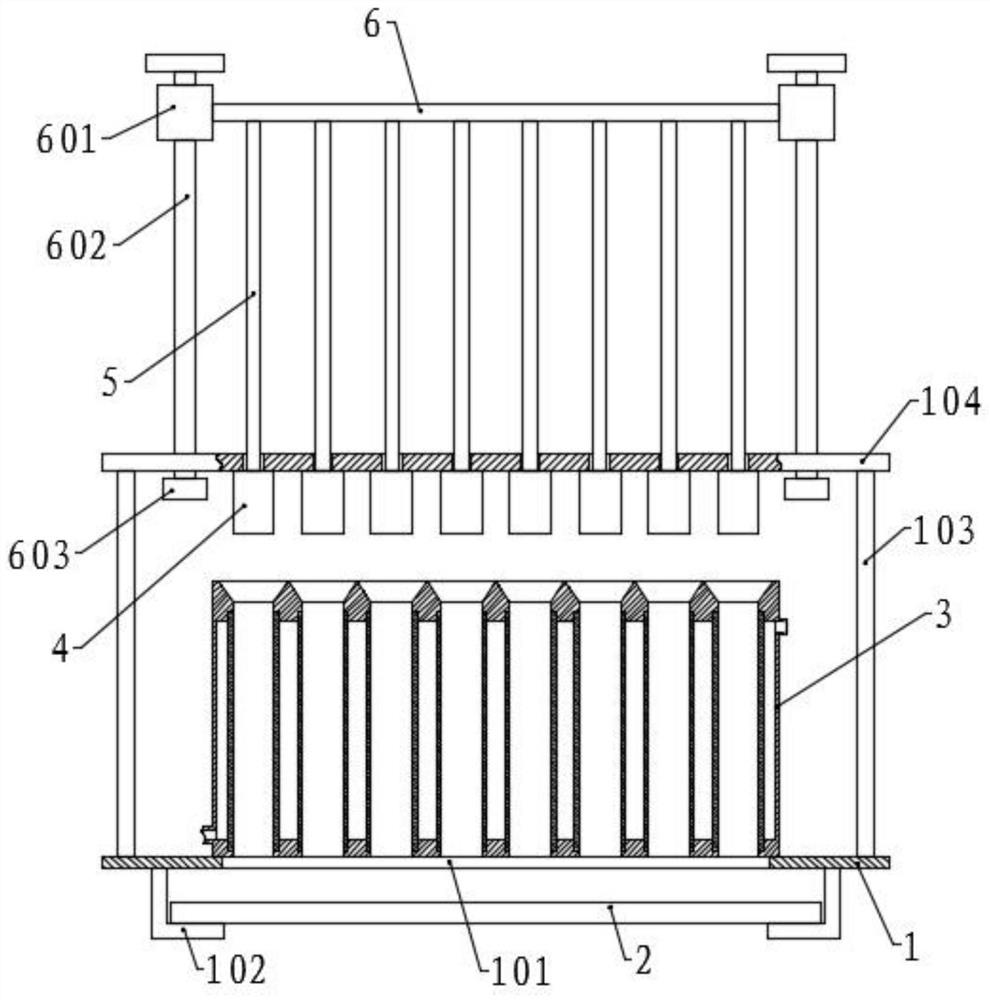

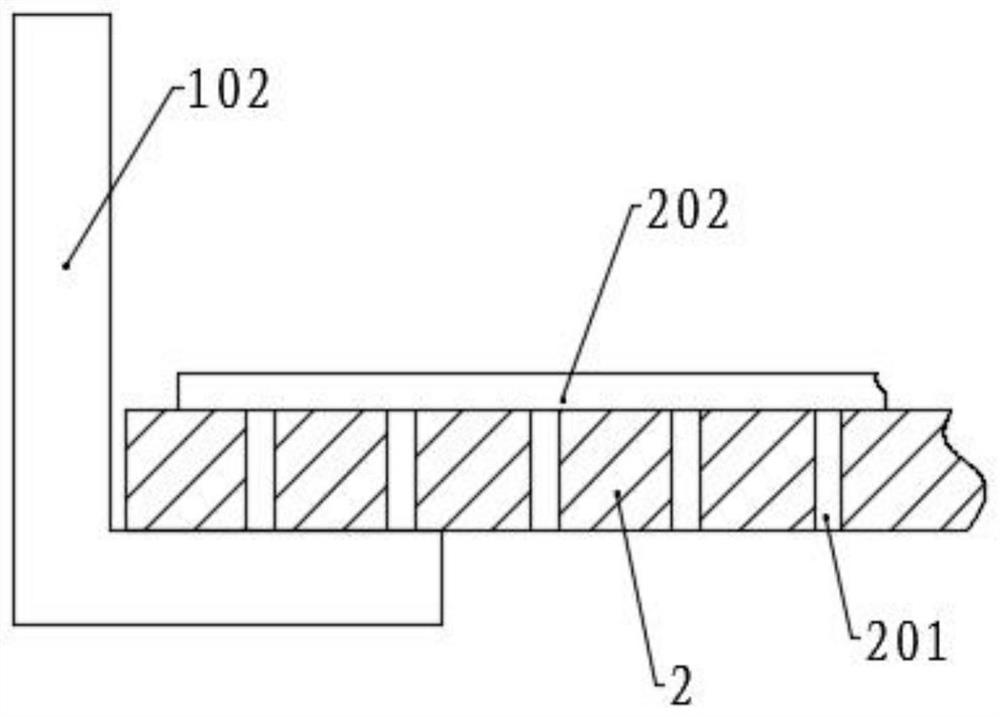

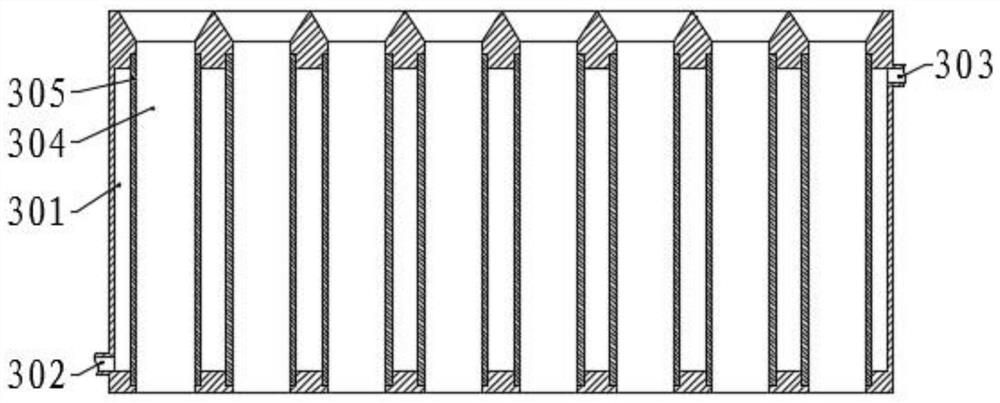

[0054] Please refer to the accompanying drawings, the present invention provides a technical solution: a green body forming and slicing equipment for food processing, including two workbenches 1 arranged symmetrically and in parallel, and the position between the two workbenches 1 is set as a section Groove 101, the top of slicing groove 101 is provided with forming box 3, and both sides of the bottom surface of forming box 3 are symmetrically fixed on two workbenches 1, and both sides of slicing groove 101 are symmetrical and slidingly connected with sealing plate 7, sealing plate 7 Both sides are symmetrically connected with moving components, the top surface of the workbench 1 is fixed with support rods 103, the tops of multiple support rods 103 are jointly fixed with a top plate 104, and a lifting component is arranged on the top plate 104, and the bottom of the lifting component is evenly connected with multiple a moving rod 5, and the bottom end of the moving rod 5 is fix...

Embodiment 2

[0067] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a first fixed cylinder 401 is fixed in the middle of the top surface of the forming block 4, a first fixed plate 402 is fixed on the top surface of the first fixed cylinder 401, and the moving rod The bottom end of 5 passes through the first fixing plate 402, and stretches into the first fixing cylinder 401, and is fixedly connected with the top surface of the molding block 4, and the outer side of the first fixing cylinder 401 corresponds to the four sidewall positions of the molding cylinder 304. There is a first brush plate 405, bristles are evenly fixed on the outer surface of the first brush plate 405, and a spring rod is fixed on the inner surface, and one end of the spring rod extends into the first fixing cylinder 401, and a magnetic plate 407 is fixed on it. A spring is provided between the plate 407 and the side wall of the first fixing cylinder 401 , and a pl...

Embodiment 3

[0071] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that the first fixing plate 402 is a cavity structure, and the first cleaning plate 408 is slidably connected to the four side walls, and the inner cavity of the first fixing plate 402 Four right-angled fixed plates are fixed in the middle, a spring is arranged between the first cleaning plate 408 and the corresponding fixed block, the inner end of the first cleaning plate 408 is fixed with a spring rod, and the inner end of the spring rod stretches into the first The inner cavity of the fixed plate 402 is fixed with a magnetic plate 407 , and an electromagnet 501 is correspondingly fixed on the moving rod 5 .

[0072]The second fixed plate 404 is a cavity structure, and the four corners are slidably connected with a right-angled second cleaning plate 409, four fixed plates are fixed in the four corners of the inner cavity of the second fixed plate 404, and the first cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com