Method for connecting target and rear panel through fusion welding

A distributed and backplane technology, applied in welding equipment, laser welding equipment, electron beam welding equipment, etc., can solve problems such as complex process, difficult processing, complex process realization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Connection of high-purity Al-0.5% Cu (wt.) alloy (purity > 99.9995%) circular target and 6061Al alloy back plate. The connection process is as follows:

[0023] 1. The 6061Al alloy back plate is shot peened to roughen the surface;

[0024] 2. Stack the Al-0.5% Cu alloy target and the 6061Al alloy back plate in the center, heat to 200-280 ° C, apply a pressure of 50-150 MPa under the press, and press the two surfaces to be connected without gaps Together;

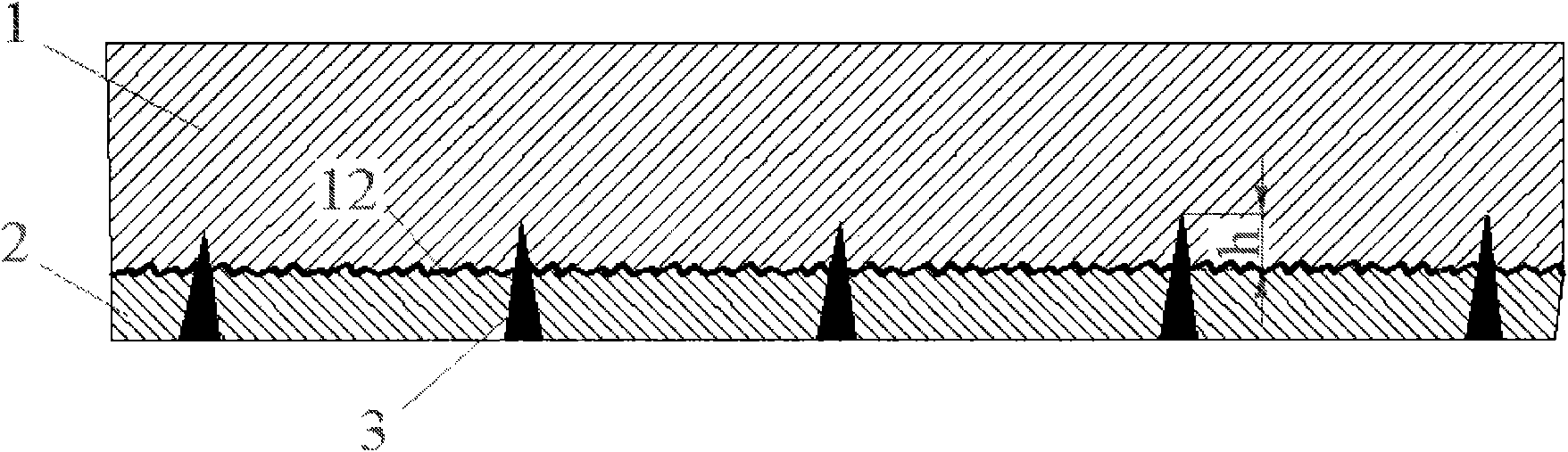

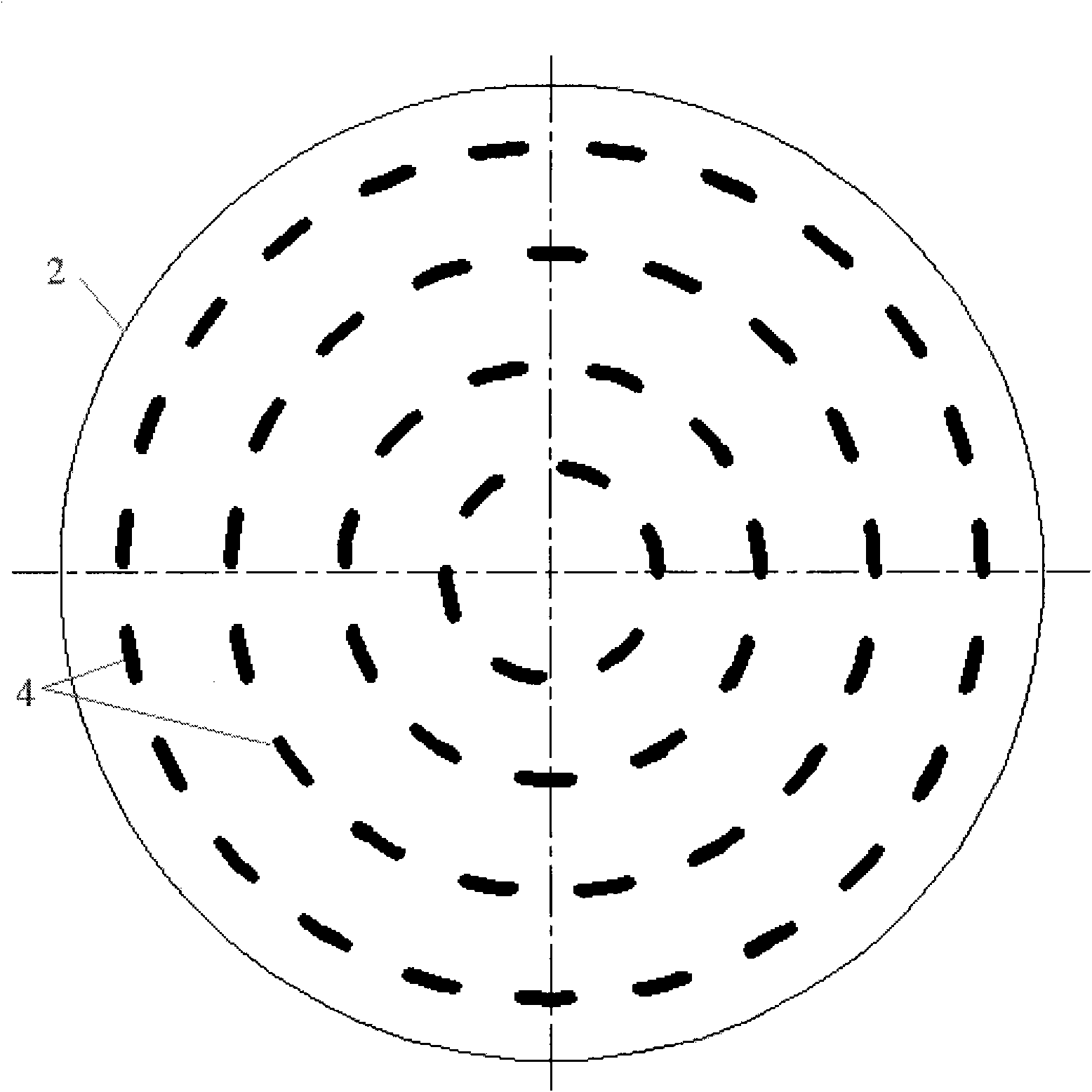

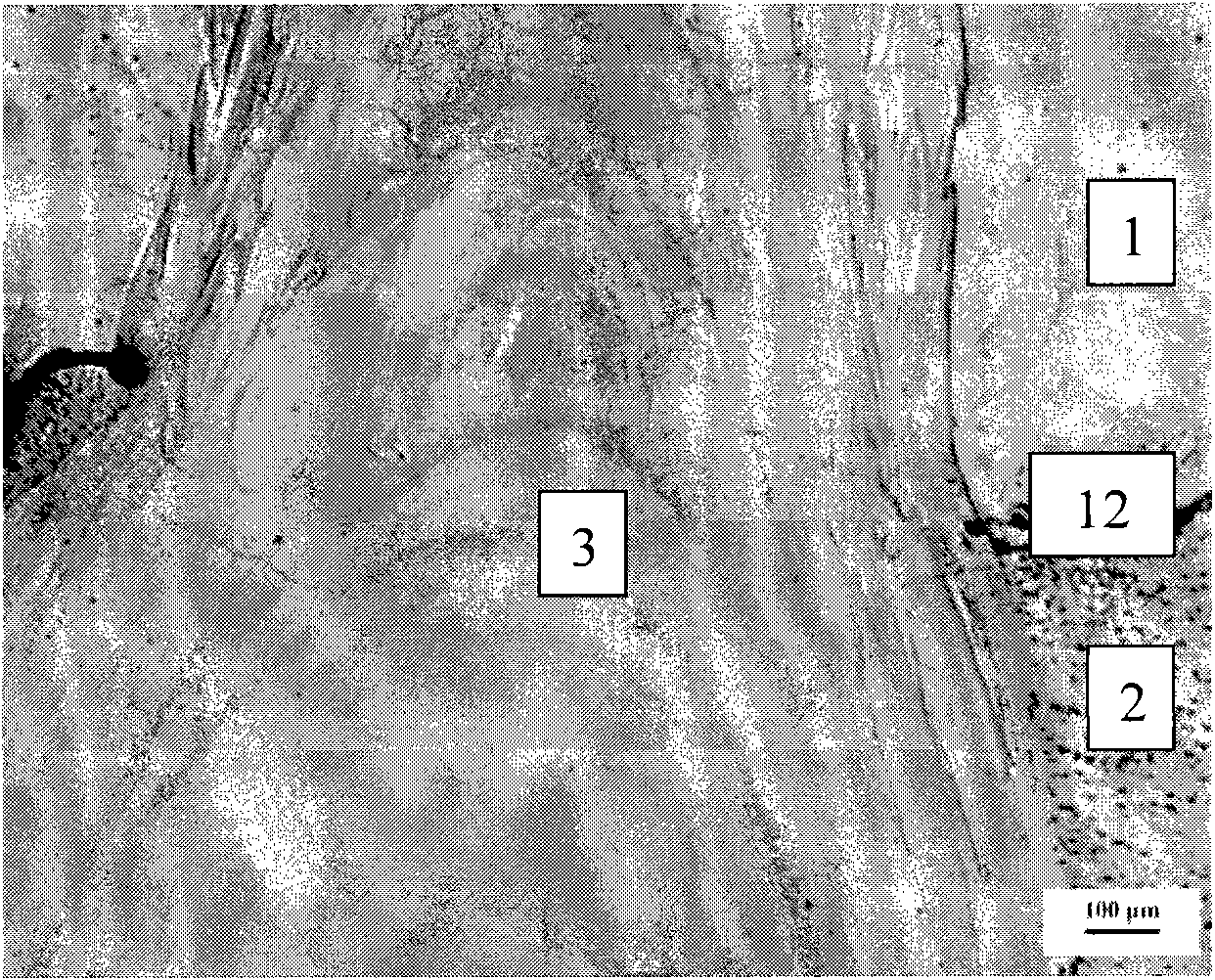

[0025] 3. Lay the pressed target and back plate components flat, and use electron beams to carry out distributed deep penetration welding from the surface of the 6061Al back plate. The interface bonding method between the back plate and the target is as follows: figure 1 shown. During welding, the start and end of welding are realized by controlling the opening and closing of the electron beam. The length of each bead is about 10mm, forming a non-continuous concentric bead array with the center of the back plate (t...

Embodiment 2

[0029] Welding of high-purity Al-4% Cu (wt.) alloy (purity > 99.999%) rectangular target and 2024Al alloy back plate. The connection process is as follows:

[0030] 1. The Al-4% Cu and 2024Al alloy backplanes are milled to roughen their surfaces;

[0031] 2. Stack the Al-4% Cu alloy target and the 2024Al alloy back plate together, heat them to 250-350°C, press the two surfaces to be connected together without gaps under a press with a pressure of 120-200MPa Together;

[0032] 3. Lay the pressed target material and the back plate assembly flat, and use the laser beam to conduct distributed deep penetration welding from the surface of the 2024Al back plate. During welding, the laser beam is controlled to turn on and off the light. The time of each welding pass about 15mm in length, formed as Figure 4 The discontinuous bead distribution pattern shown. The welding depth is controlled by adjusting the output power of the laser beam, scanning speed, etc., and the back plate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com