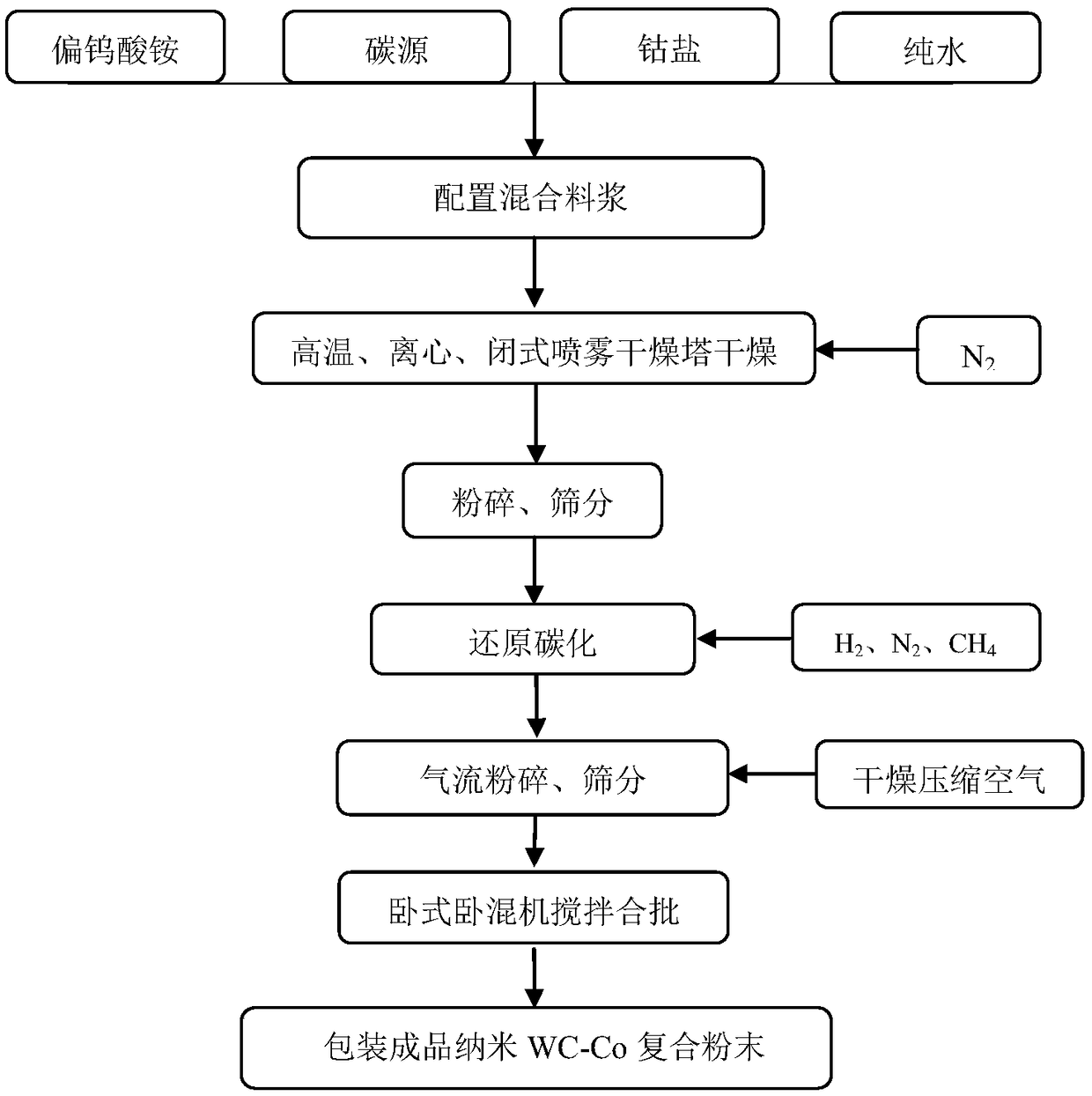

Method for preparing nanometer WC-Co composite powder through high-temperature spray drying short process

A composite powder, spray drying tower technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the quality control of WC-Co composite powder, precursor powder easy to absorb moisture gelatinization, Reduce the service life of equipment and other problems, and achieve the effect of easy control of powder composition, fine grain size, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Configure the mixed slurry: configure the WC-6Co composite powder according to the Co content of 6wt%, and mix the water-soluble cobalt acetate with a mass fraction of 11.56wt%, the water-soluble ammonium metatungstate with a mass fraction of 57.35wt%, and the water-soluble ammonium metatungstate with a mass fraction of 31.09wt%. Glucose is put into pure water heated to 75 ° C in order, accounting for 2 / 3 of the storage tank volume (pure water is calculated on the basis of 40 wt% of the total weight of the material), mixed, heated and stirred for 2 hours, and the viscosity of the resulting mixed slurry is 5000 ± 500mPa.s, pH=4±0.5;

[0039] 2) Spray drying crystallization: the mixed slurry obtained in step 1) is transported to a closed centrifugal high-temperature spray drying tower by a material pump for drying, and nitrogen gas is introduced into the closed centrifugal spray drying tower, and the pressure inside the tower is controlled at 2.4±0.1Kpa , the inlet tem...

Embodiment 2

[0052] 1) Configure the mixed slurry: configure the WC-6Co composite powder according to the Co content of 6wt%, and mix the water-soluble cobalt acetate with a mass fraction of 11.56wt%, the water-soluble ammonium metatungstate with a mass fraction of 56.45wt%, and the water-soluble carbon with a mass fraction of 31.99wt%. source (51.5% glucose + 48.5% citric acid), put them into pure water heated to 75°C in order, accounting for 2 / 3 of the storage tank volume (pure water is calculated as 40wt% of the total weight of the material), mixed and heated for 2 hours, and the obtained mixture The viscosity of the slurry is 4000±500mPa.s, pH=4±0.5;

[0053] 2) Spray drying crystallization: the mixed slurry obtained in step 1) is transported to a closed centrifugal high-temperature spray drying tower by a material pump for drying, and nitrogen gas is passed into the closed centrifugal spray drying tower, and the pressure inside the tower is controlled at 2.5 ± 0.1Kpa , the inlet tempe...

Embodiment 3

[0060] 1) Configure the mixed slurry: configure the WC-6Co composite powder according to the Co content of 6wt%, and mix the water-soluble basic cobalt carbonate with a mass fraction of 5.6wt%, the water-soluble ammonium metatungstate with a mass fraction of 60.07wt%, and the water-soluble ammonium metatungstate with a mass fraction of 34.33wt%. Glucose, which is stable, is put into pure water heated to 85°C in order, accounting for 2 / 3 of the storage tank volume (pure water is calculated as 40wt% of the total weight of the material), mixed and heated for 2 hours, and the viscosity of the obtained mixed slurry is 6000 ± 500mPa. s, pH=4.5±0.5;

[0061] 2) Spray drying crystallization: the mixed slurry obtained in step 1) is transported to a closed centrifugal high-temperature spray drying tower by a material pump for drying, and nitrogen gas is passed into the closed centrifugal spray drying tower, and the pressure inside the tower is controlled at 2.5 ± 0.1Kpa , the inlet temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com