Grinding machine

A grinding machine and frame technology, applied in grinding machines, machine tools suitable for grinding the edge of workpieces, machine tools for surface polishing, etc., can solve the problems of slow speed, inconvenient production efficiency, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

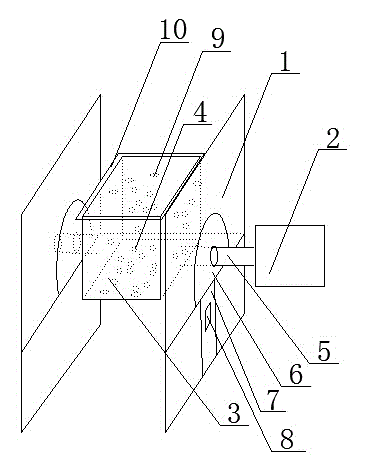

[0012] A grinding machine, comprising a frame 1, a motor 2, the present invention also includes a grinding bucket 3, a grinding sand 4 is placed in the grinding bucket 3, a rotating shaft 5 is arranged at both ends of the grinding bucket 3, and one end of the grinding bucket 3 is open, The opening is covered with a cover 10; on the inner wall of the grinding bucket 3, some protrusions 9 are arranged; on the frame 1, two bearings 6 are arranged; the rotating shaft 5 of the grinding bucket 3 is supported on the bearing 6 on the frame, and the rotating shaft One end of 5 is connected with motor 2. The bottom of frame 1 is provided with switch control box 7, and motor switch button 8 is arranged on the box wall of switch control box 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com