Granulating machine used for producing chicken feed and using method of granulating machine

A pellet mill, chicken feed technology, applied in feed, application, grain processing and other directions, can solve the problems of small grinding area of materials, reduced material utilization rate, low feeding efficiency, etc., to ensure quality, save manpower, improve quality material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

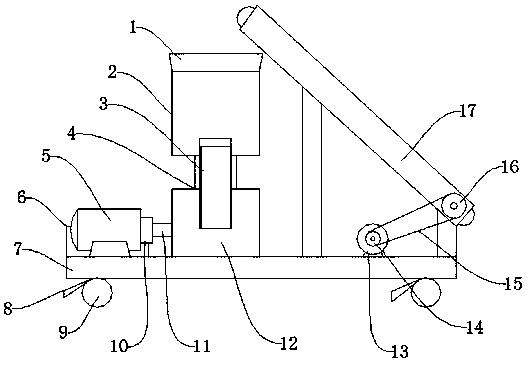

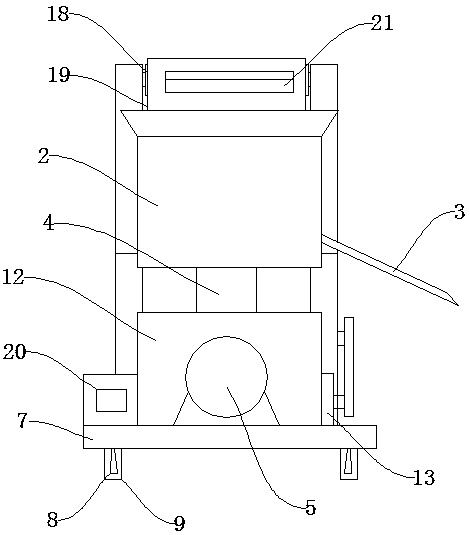

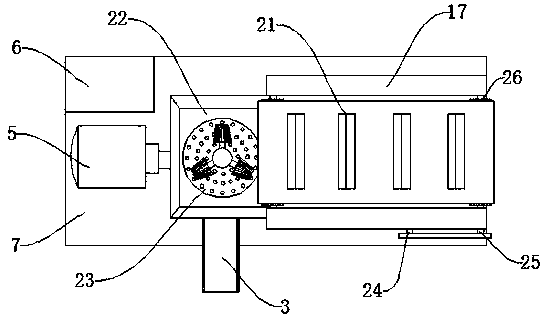

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Such as Figure 1-Figure 6 As shown, a pellet mill for chicken feed production includes a bottom plate 7, a pelletizing bin 2 and a support 17, and universal wheels 9 are fixed at the four corners of the lower end of the bottom plate 7, through which the universal wheels 9 can be To make the device move conveniently, the universal wheel 9 is provided with a wheel lock 8, the upper end side of the base plate 7 is provided with a motor one 5, and one side of the motor one 5 is provided with a controller 6, and the controller 6 An operation panel 20 is embedded on one side wall, and the transmission output end of the motor one 5 is fixed with a coupling 10 through bolt connection, and a transmission shaft 11 is hinged on the coupling 10, through which the coupling 10 The motor one 5 can be connected with the transmission shaft 11, the transmission shaft 11 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com