Emulsified asphalt production equipment

A production equipment and technology for emulsified asphalt, applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, petroleum industry, etc., can solve the problems of low degree of automation, cumbersome operation, short life, etc. area, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

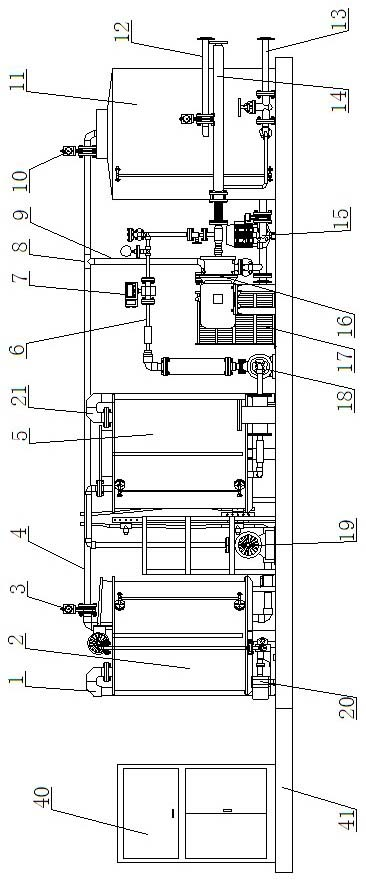

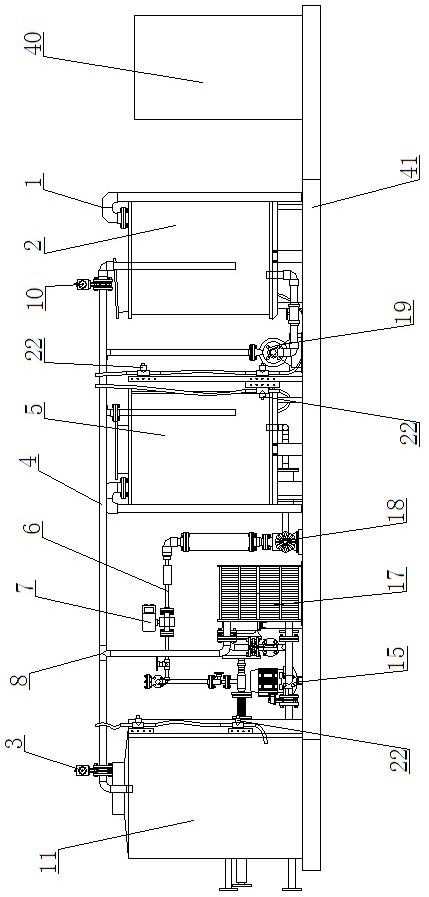

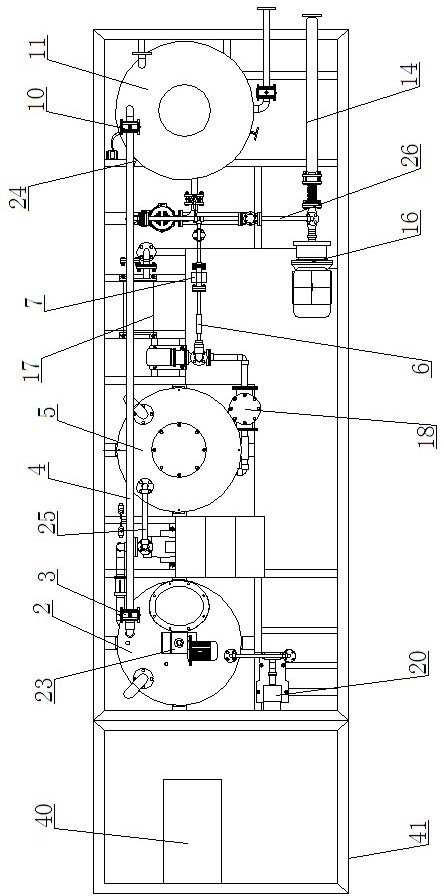

[0028] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0029] A kind of emulsified asphalt production equipment, such as Figure 1-Figure 3 As shown, it includes a colloid mill 16, a mixing tank 2, a hot water tank 11 and a PLC control system 40. The hot water tank 11 is also provided with at least one layer of heat-conducting oil coils and a temperature sensor 24 and a float switch 22 connected to the PLC control system 40. The hot water tank 11 is connected to the blending tank 2 through the hot water pipe 4. The two ends of the water pipe 4 connected to the hot water tank 11 and the mixing tank 2 are respectively equipped with a control valve 10 and a control valve 3 (such as a pneumatic butterfly valve); the mixing tank 2 is provided with a float switch 22 connected to the PLC control system 40 , the outlet end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com