Multi-angle machining roller manufacturing device

A manufacturing device, multi-angle technology, applied in the direction of injection device, manufacturing tool, grinding drive device, etc., can solve problems such as affecting production efficiency and reducing grinding efficiency of grinding wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

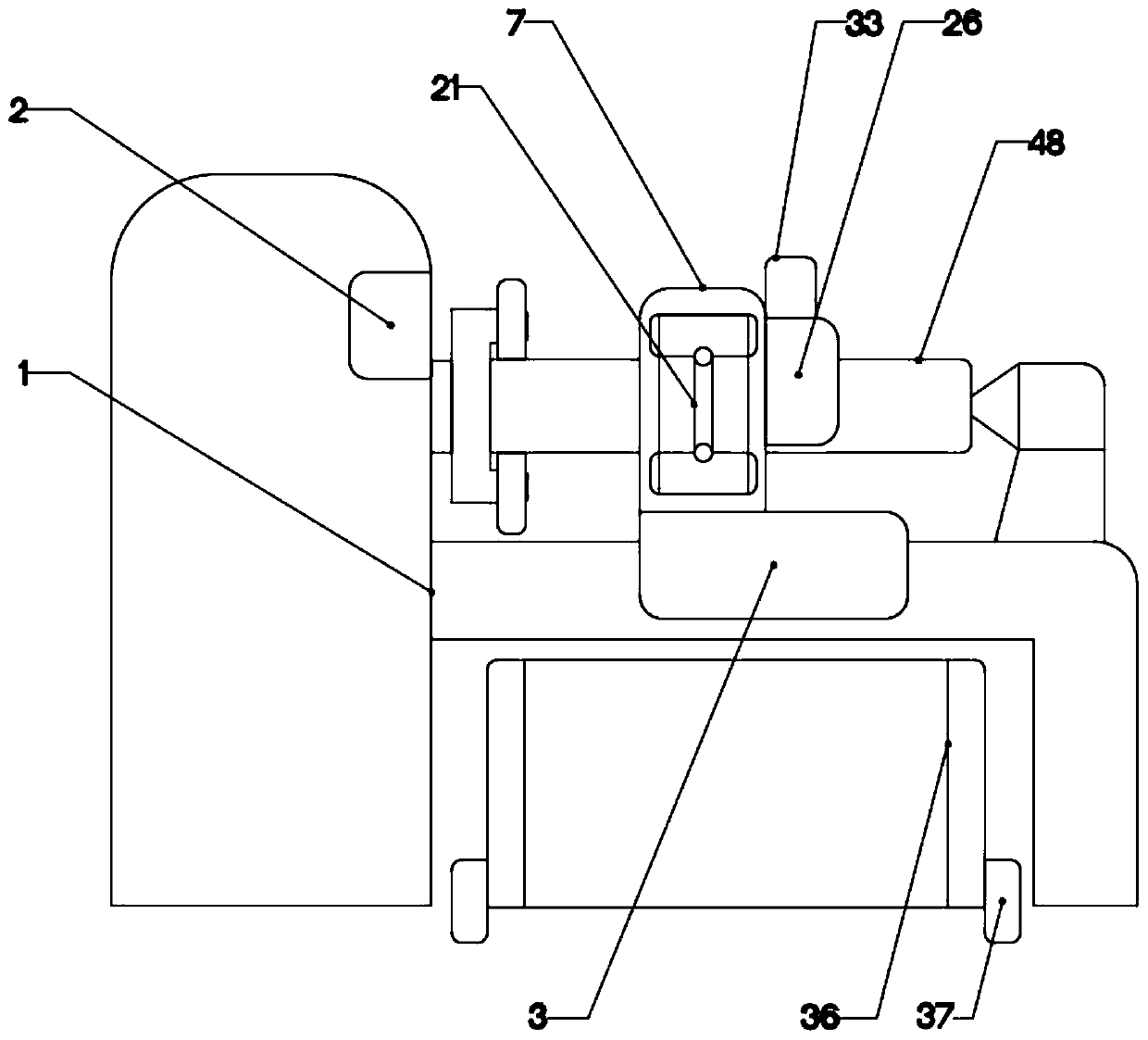

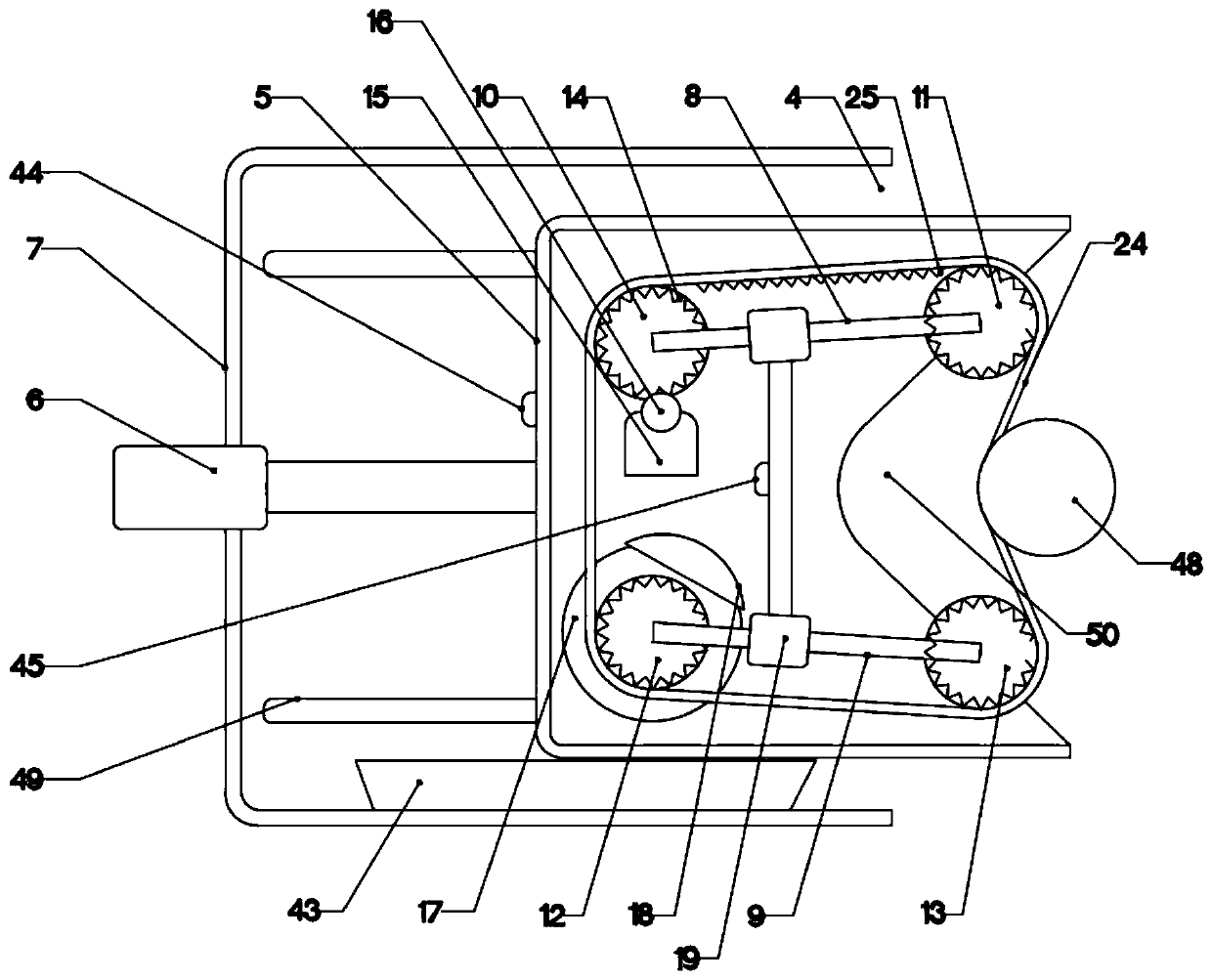

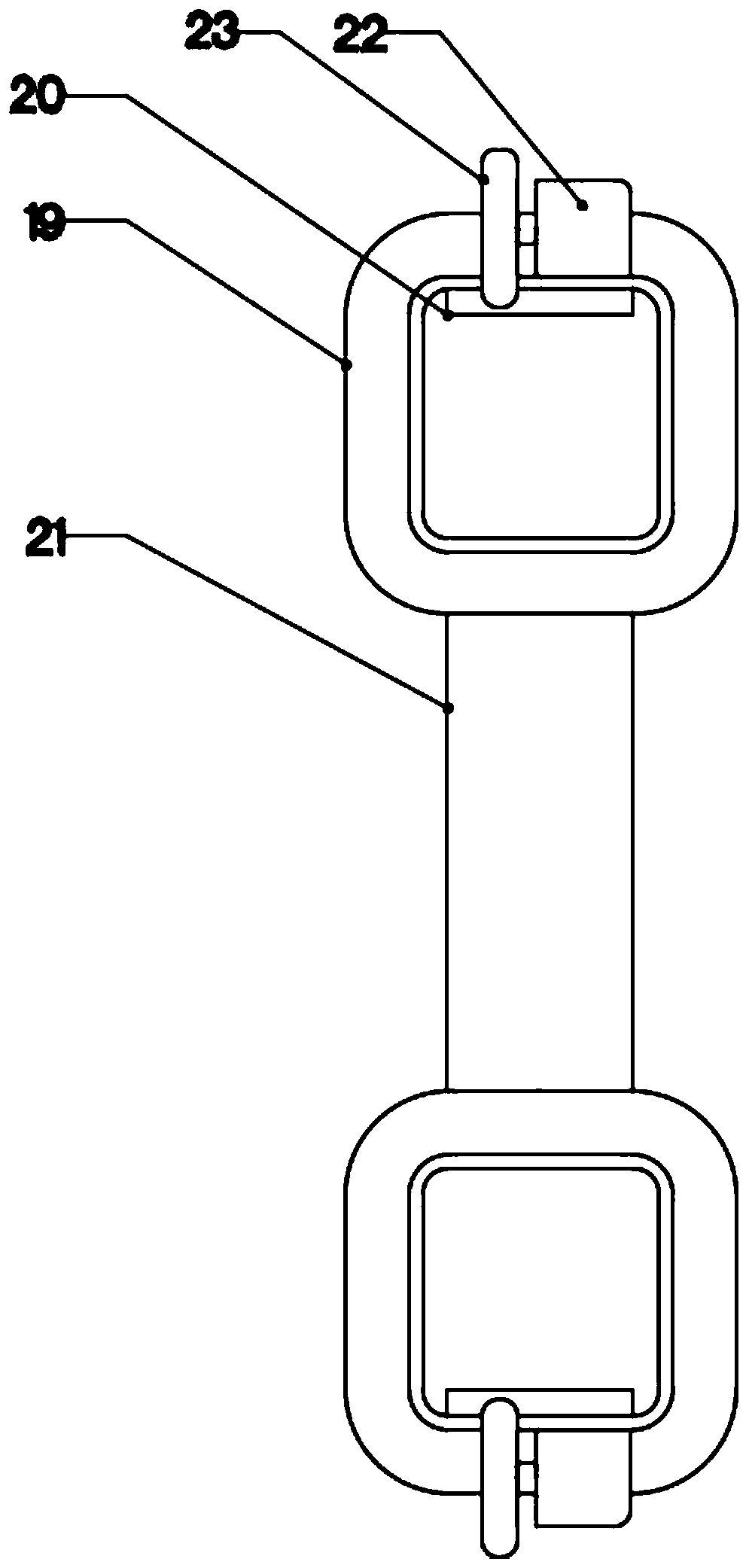

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 shown.

[0024] In this embodiment, the model of the controller 2 is S7-200, and the signal output terminal of the controller 2 is connected with the pneumatic telescopic rod 1 6, the pneumatic telescopic rod 2 21, the air motor 1 15, the air motor 2 22, and the linear motor 1 30 , suction pump one 32, suction pump two 34, and the signal input terminals of the air pressure sensor 45 are electrically connected, and the power output terminal of the controller 2 is connected to the linear motor one 30, the suction pump one 32, the suction pump two 34, The power input end of the air pressure sensor 45 is electrically connected.

[0025] The invention point of the application lies in the structural design of the band grinding device, in this device in conjunction with the attached figure 2 and 3 , the belt-shaped grinding device can make the grinding belt 24 clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com