Grinding tool and grinding method for guide pipe orifice angle

A technology for grinding tools and nozzles, which is applied in the manufacturing field of aircraft catheters. It can solve the problems of low efficiency of catheter nozzle angle grinding, unstable grinding angle size, and non-durability, so as to achieve stable and reliable grinding quality, shorten the grinding cycle, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

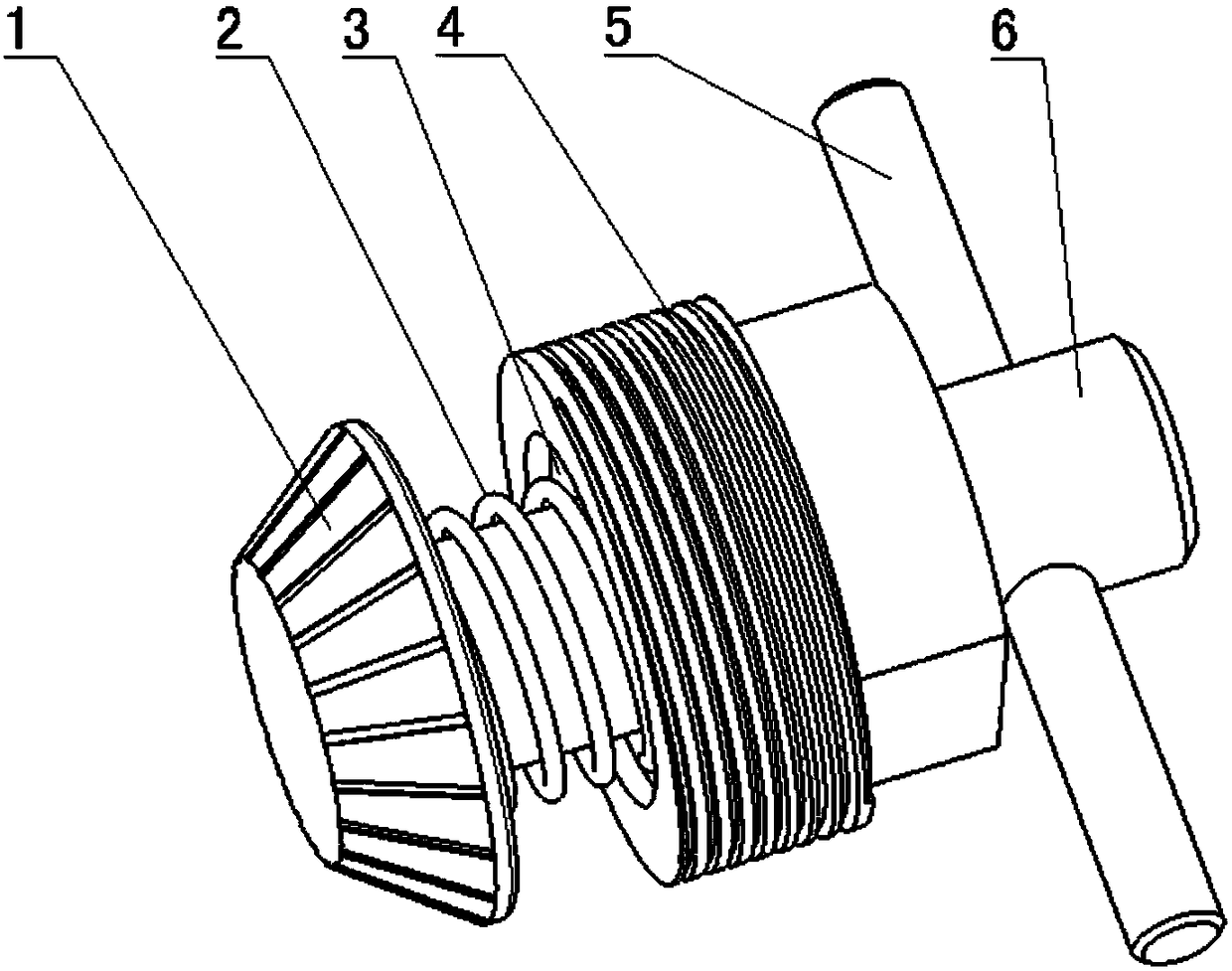

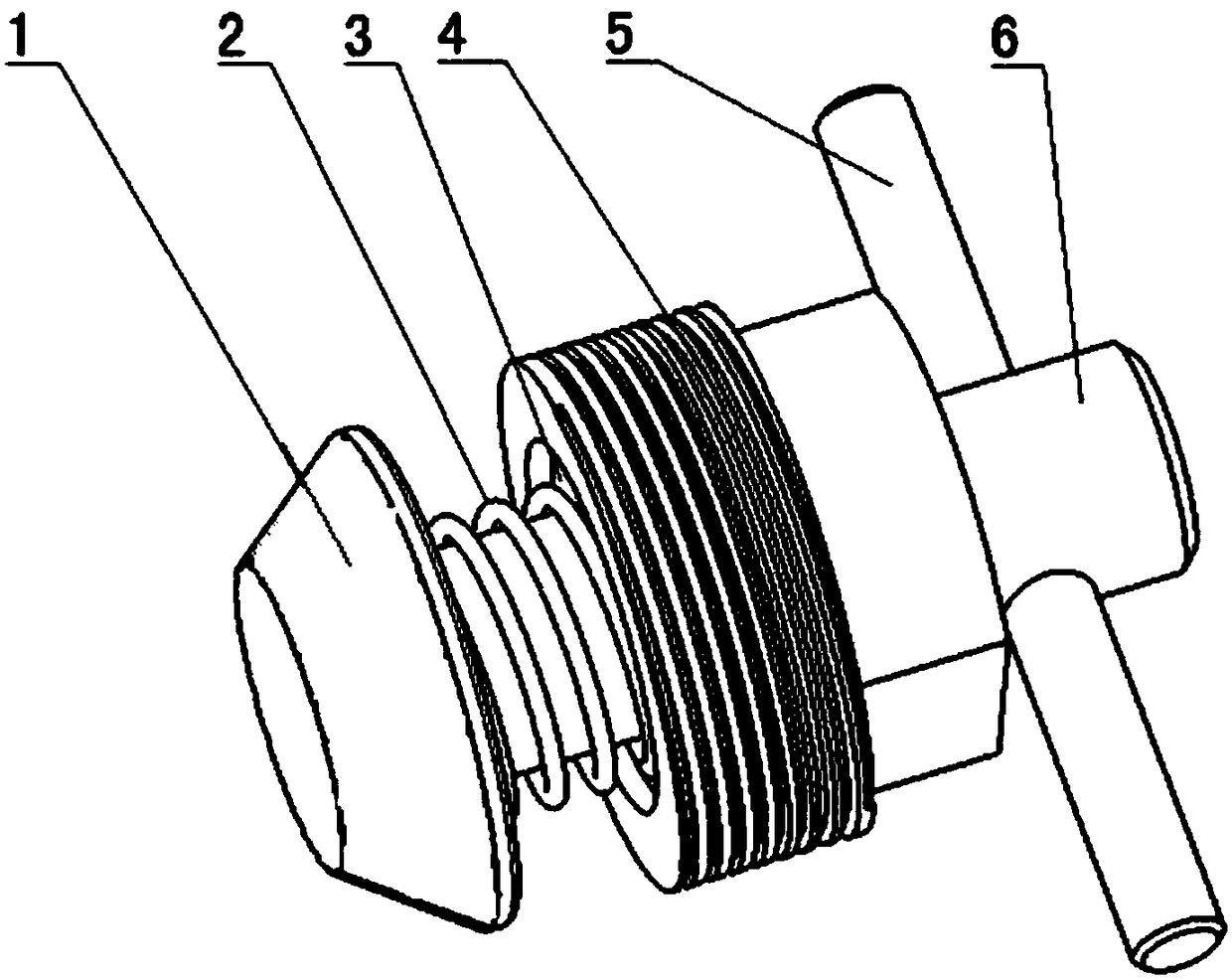

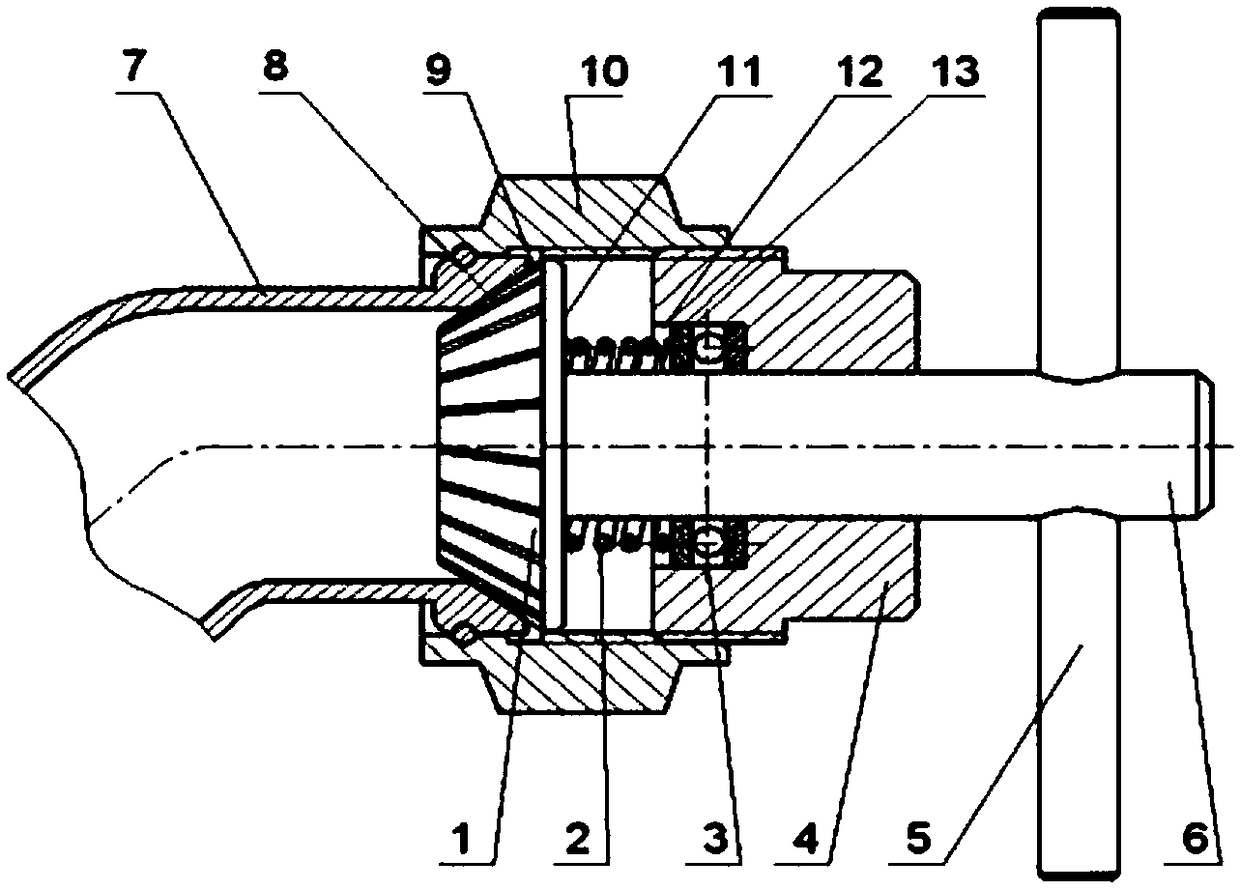

[0014] see figure 1 , a conduit nozzle angle grinding tool, the grinding tool includes a grinding head 1, a guide rod 6, a compression spring 2 and a threaded guide sleeve 4, the grinding head 1 is located at the front end of the guide rod 6, and the grinding head 1 is a tapered The rigid structure of the grinding surface 9, the tapered grinding surface 9 matches the nozzle angle surface 8 of the conduit, the threaded guide sleeve 4 is a rotating body, the center of which has a guide hole and is embedded with a bearing 3, and its outer side is provided with External thread, the guide rod 6 is inserted into the guide hole, and the compression spring 2 is located between the grinding head 1, the guide rod 6 and the bearing 3.

[0015] The above-mentioned grinding head 1 is divided into a rough grinding head and a fine grinding head. In the rough grinding head, several grinding grooves are evenly distributed on the conical grinding surface 9. The rough grinding head is only used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com