Spinneret plate and processing method thereof

A processing method and spinneret technology, which are used in spinneret assemblies, textiles and papermaking, etc., can solve the problems of affecting the service life of equipment, difficult to process spinneret holes, and difficult to clean spinneret holes, so as to reduce the processing time. cost, improve the smoothness of the inner wall, and the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

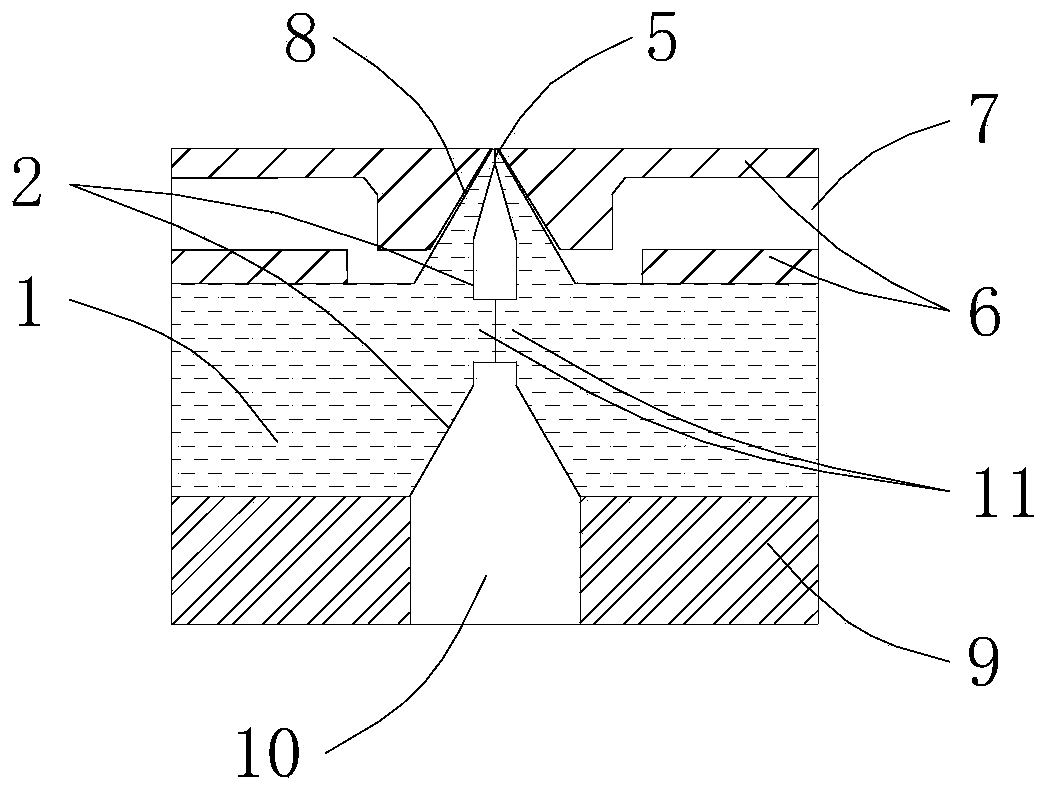

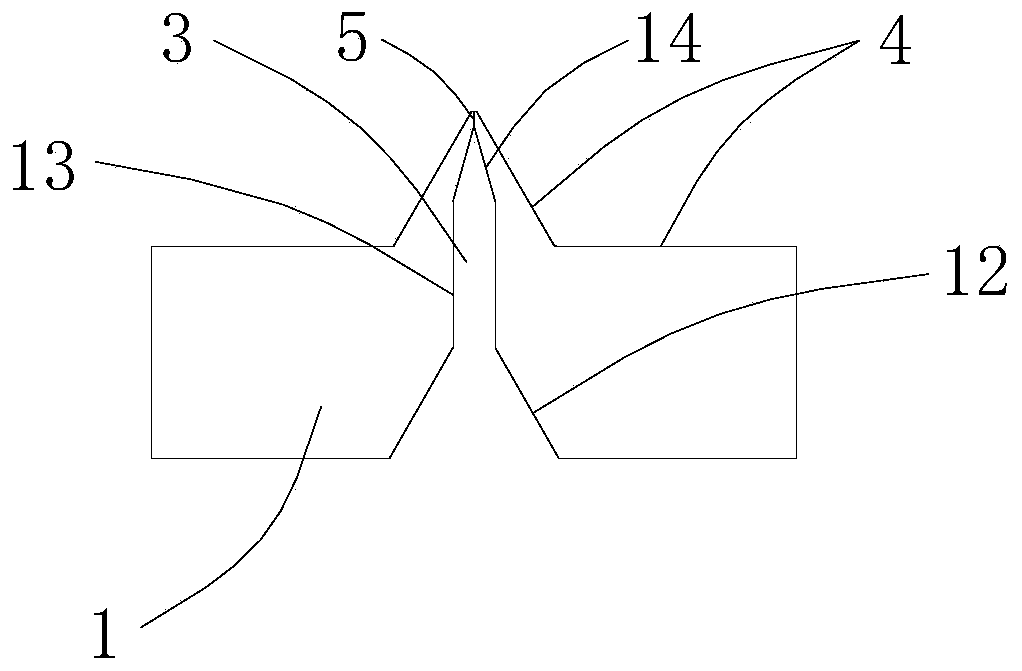

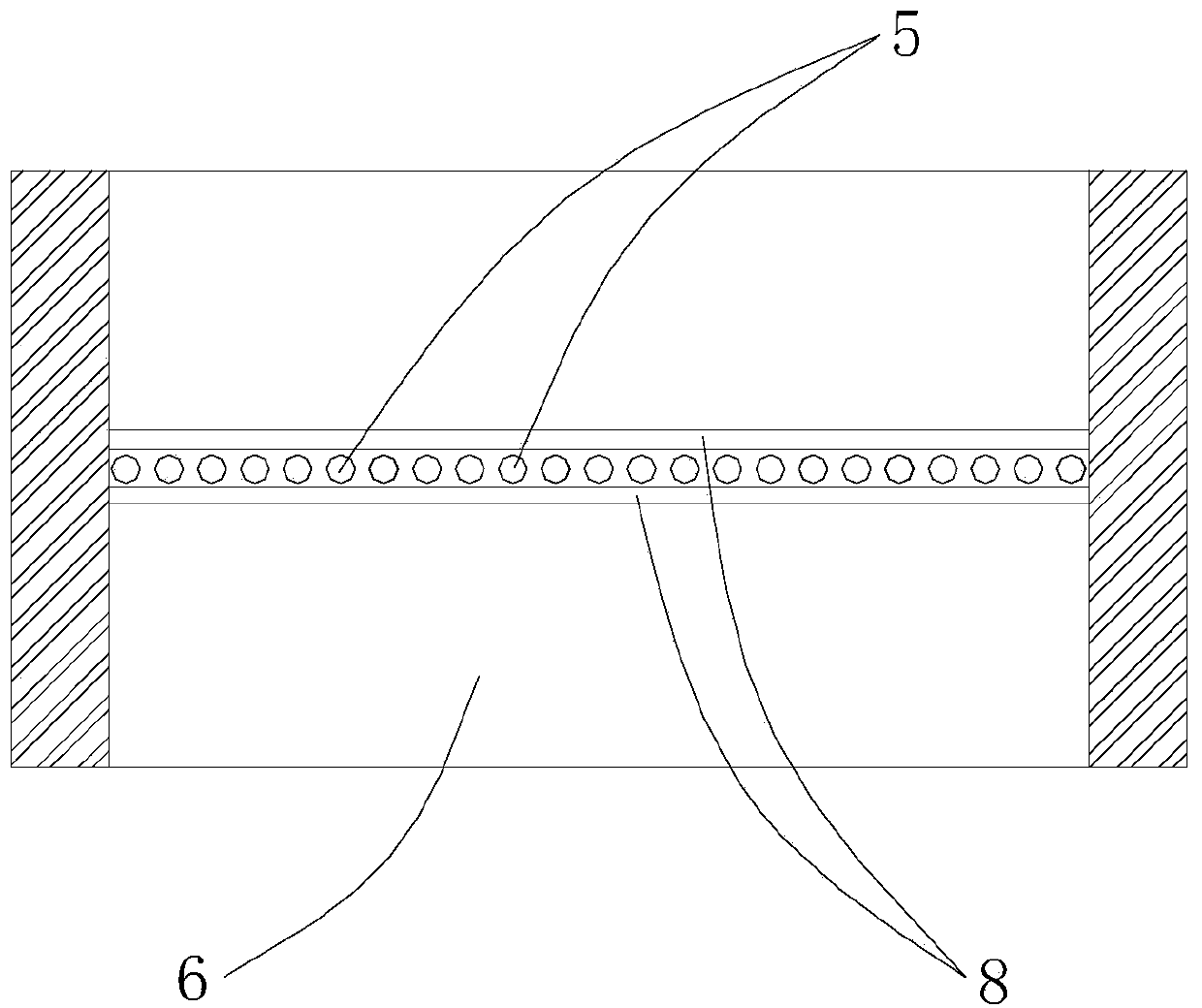

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] see Figure 1-5 shown, where figure 1 and figure 2 The dissection location is different. Above-mentioned a processing method for spinneret, comprises the following steps:

[0029] (1) Divide the first plate body into two along the longitudinal centerline direction, respectively on the butt joint surfaces of the two first sub-boards 1 (the butt joint surfaces mentioned here refer to the two first sub-boards 1 facing each other) The first groove 2 is processed on the side), so that after the two first sub-boards 1 are spliced, the first grooves 2 on both sides are spliced with each other to form an inner runner 3 . The inner runner 3 extends along the longitudinal centerline of the first plate body and is closed at both ends, and the inner runner 3 is closed at the top and open at the bottom. That is, the inner runner 3 is entirel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com