Novel truck hub bearing

A wheel hub bearing, truck technology, applied in the direction of bearings, bearing components, roller bearings, etc., can solve the problems of difficult grinding, large outer ring width, high equipment requirements, etc., to achieve strong adaptability, reduce grinding difficulty, and difficult Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the drawings and embodiments.

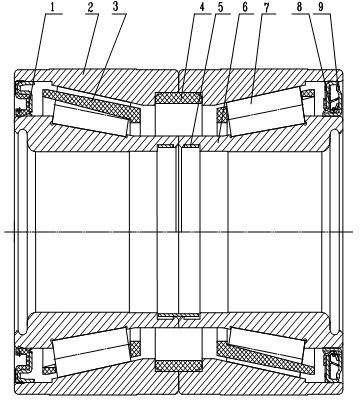

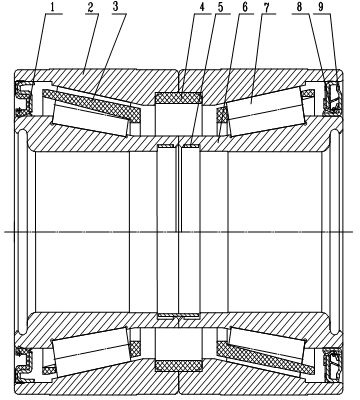

[0010] Such as figure 1 In the new truck wheel hub bearing shown, the inner ring 6 and the outer ring 2 are two-piece structure. The outer inner diameter of the two outer rings 2 is designed with a groove, and the nylon lock ring 4 and the two outer rings 2 are interference-connected. The two inner rings 6 The spring clamp ring 5 is used to fix the connection. The rolling element 7, the inner ring 6, and the cage 3 form an assembly, which is combined with the two outer rings 2. The first seal ring 1 and the second seal ring 8 are installed on both sides, and the second seal ring 8 Install the dust cover 9 outside.

[0011] The assembly process of the new truck wheel hub bearing is as follows: put the rolling element 7 into the pocket of the cage 3, and then put it into the inner ring 6 to form the inner assembly of the cage 3, the rolling elements 7, and the inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com