High-pressure water jet punching-drilling-expanding-cutting integrated antireflection device for coal seam, and related method

A high-pressure water jet and coal seam technology, which is applied in the fields of fluid extraction, drilling with liquid/gas jets, drill bits, etc., can solve the problems of accelerating the wear of drill pipes, reducing the service life of drill pipes, the danger of large injection holes, etc., and improving work efficiency. , Improve drilling efficiency and avoid the effect of drilling offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

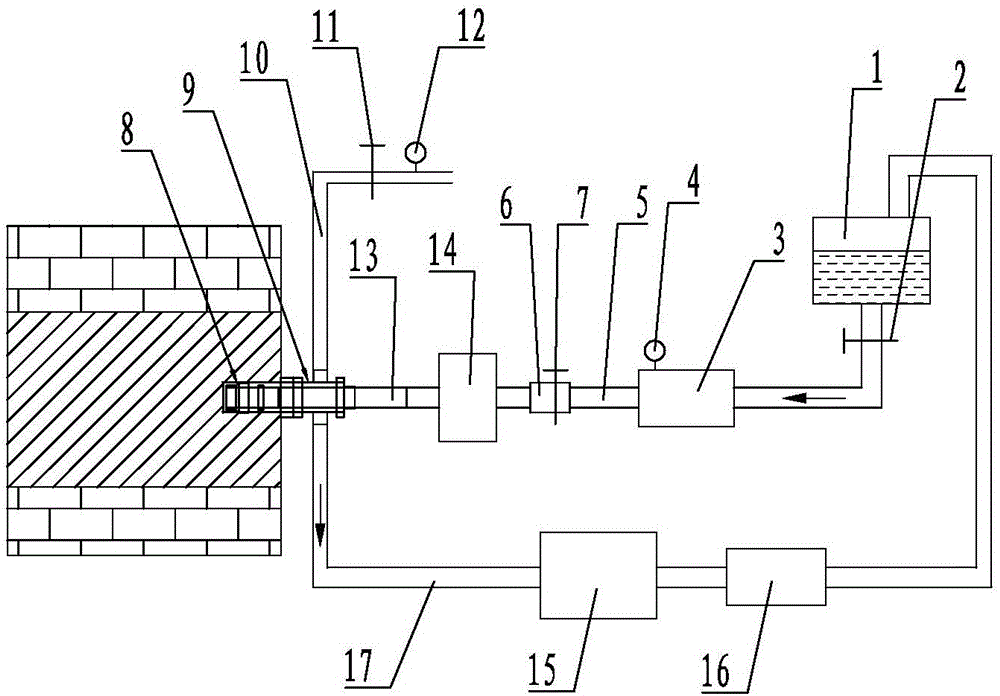

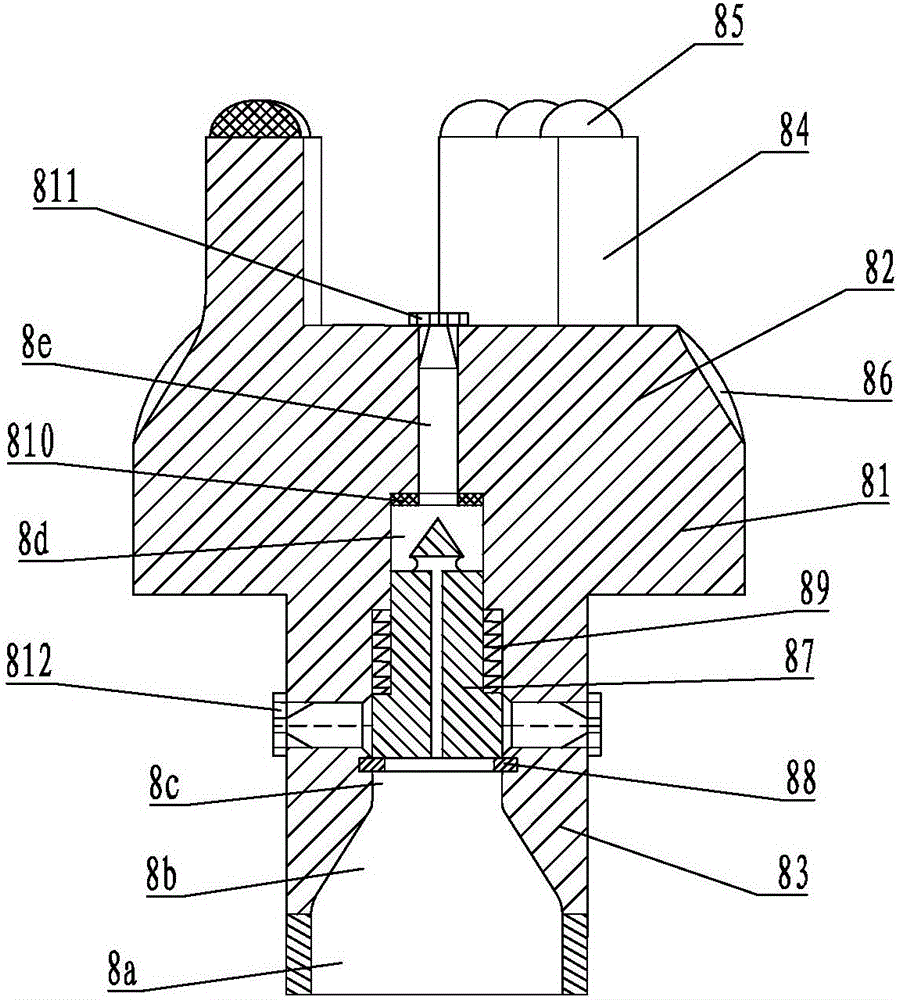

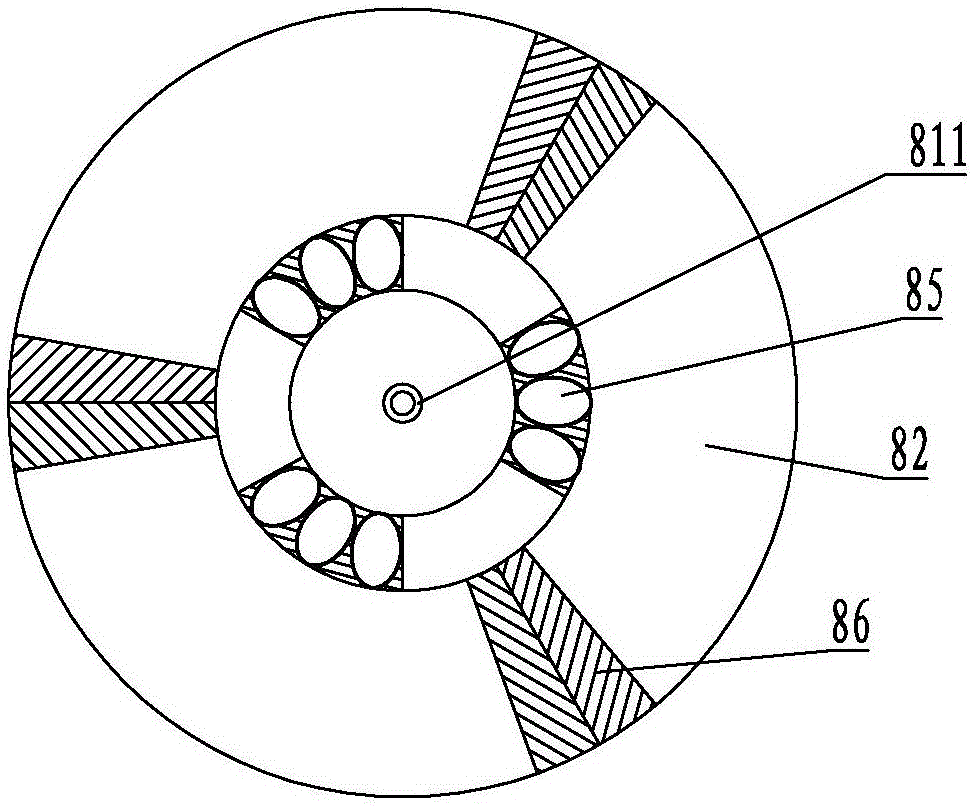

[0037] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a drilling machine 14, a drill rod 13 and a drill bit 8, and the drill rod 13 is a hollow structure. The drill bit 8 includes a cylindrical body 81. The front end of the body 81 extends forward to form a coaxial truncated conical reaming part 82. The reaming part 82 is small in front and large in the rear. At least two reaming knives 86 are uniformly fixed in the circumferential direction of the surface, and the number of the reaming knives 86 is adjusted according to actual needs. In this embodiment, three reaming knives 86 on the conical surface of the reaming portion 82 are preferably uniformly distributed in the circumferential direction. , and the included angle between the reaming cutters 86 is 120°. The reaming knives 86 are diamond blades, and the top of each reaming knife 86 is arc-shaped. The small end face of the reaming portion 82 extends forward to form at least three dri...

Embodiment 2

[0044] Such as Figure 5 As shown, a coal seam high-pressure water jet punching-drilling-expanding-cutting integrated anti-reflection method includes the following steps:

[0045] (1) In the preparation stage, install the drilling rig, drill pipe and drill bit at the underground drilling position, and pile up the first water tank and the second water tank with material stones, fill the first water tank with water, adjust the position of the drilling machine and arrange the high-pressure waterway, And the water guiding tail joint is fixedly connected with the drill pipe.

[0046] (2) Pressure test drilling, drilling 1m.

[0047] (3) Install the air-water separator, put the front section and the back section of the air-water separator on the drill pipe, and install the front section into the drill hole, inflate the rubber sleeve outside the front section to expand the rubber sleeve and drill the hole Fit the wall, adjust the two holes in the back section to be arranged one abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com