Production device for crystallized honey

A production device and honey technology, applied in the direction of food science, etc., can solve the problems of low degree of automation, small specific gravity of crystalline phase honey, and inability to directly feed materials, etc., achieve uniform and white color, rapid and uniform crystallization, and reduce the difficulty of grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

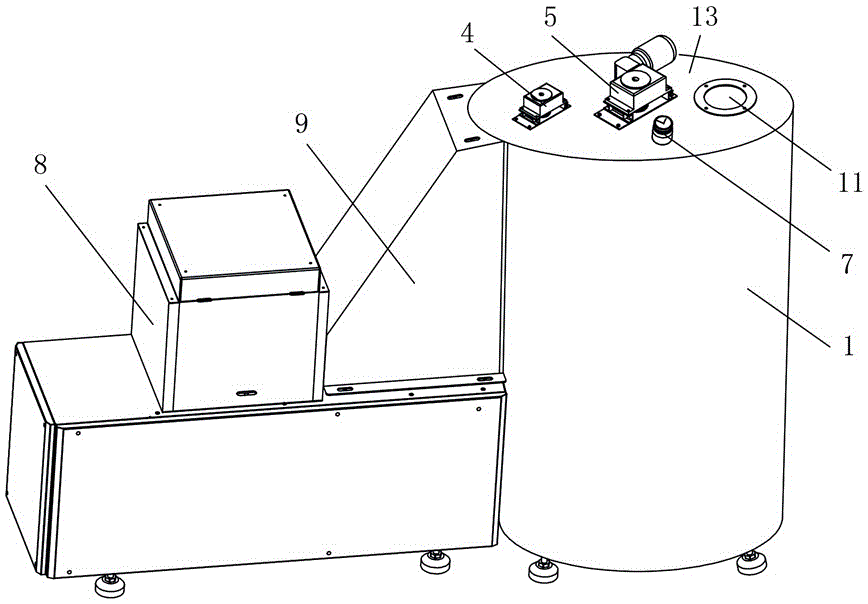

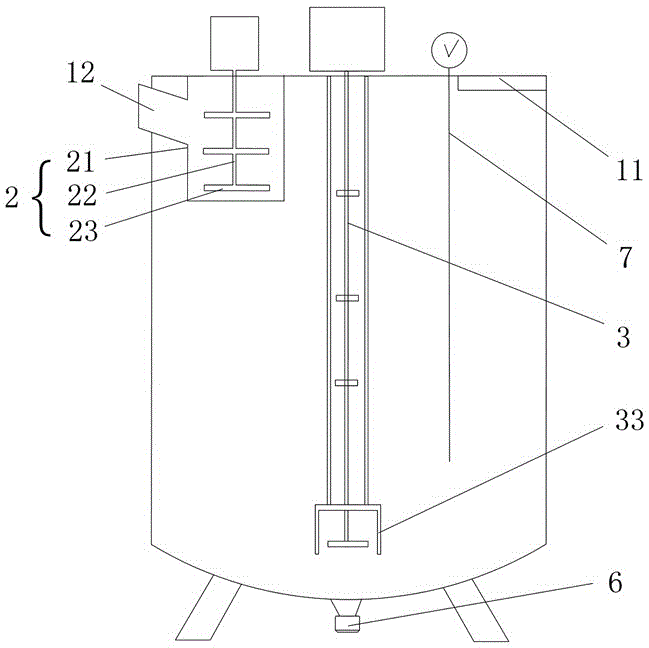

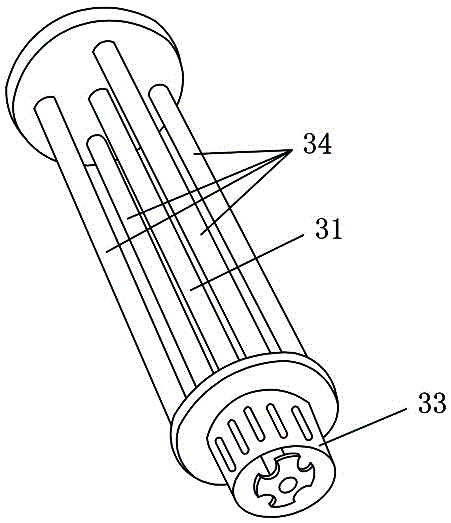

[0040] Such as Figure 1 to Figure 8 As shown, the present invention provides a production device for crystallized honey, comprising a tank body 1, the tank body 1 is provided with a first feeding port 11 for injecting liquid phase honey and a second feeding port for injecting crystal phase honey 12. The tank body 1 is provided with a matching pre-cutting mechanism 8 and a conveyor belt mechanism 9. The pre-cutting mechanism 8 is used to pre-cut the solid crystal phase honey and then transfer it to the second feeding port 12 through the conveyor belt mechanism 9. The tank body 1 is provided with a matching pre-grinding homogeneous mechanism 2 and a high-shear emulsifying and stirring mechanism 3, and the pre-grinding homogeneous mechanism 2 is located at the second feeding port 12 for further grinding the cut crystalline phase honey Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com