Bilateral discharge machine

A technology of electric discharge machine and frame, which is used in metal processing equipment, manufacturing tools, metal sawing equipment, etc., can solve the problems of complex structure, failure to meet the requirements of use, and failure of grinding accuracy to meet the processing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

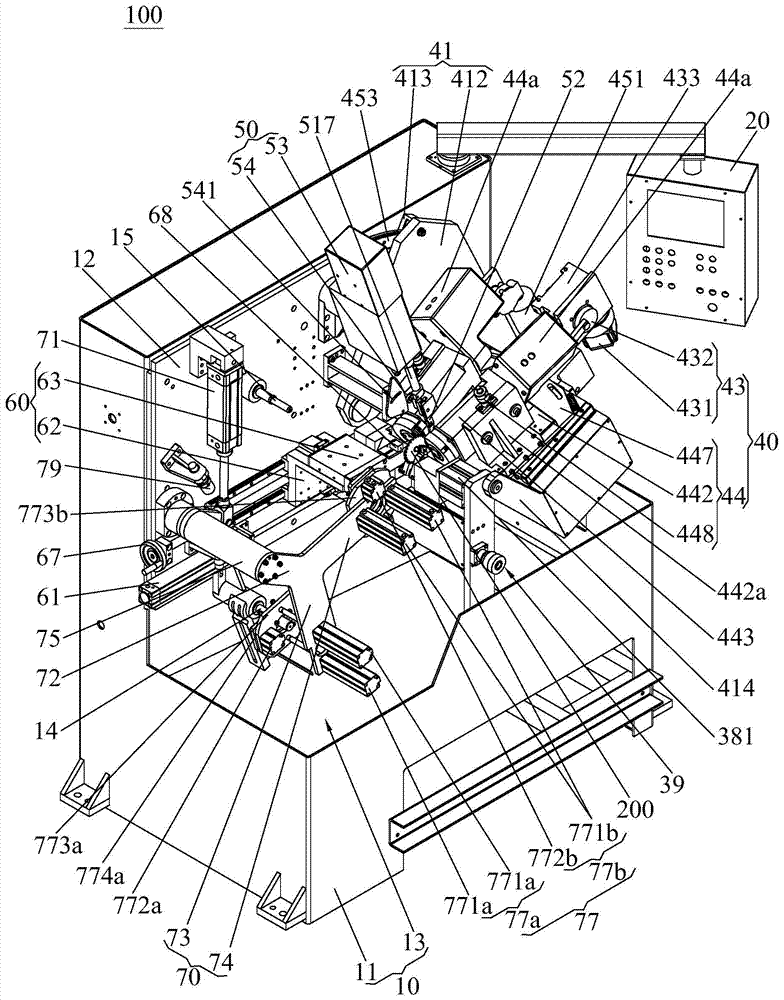

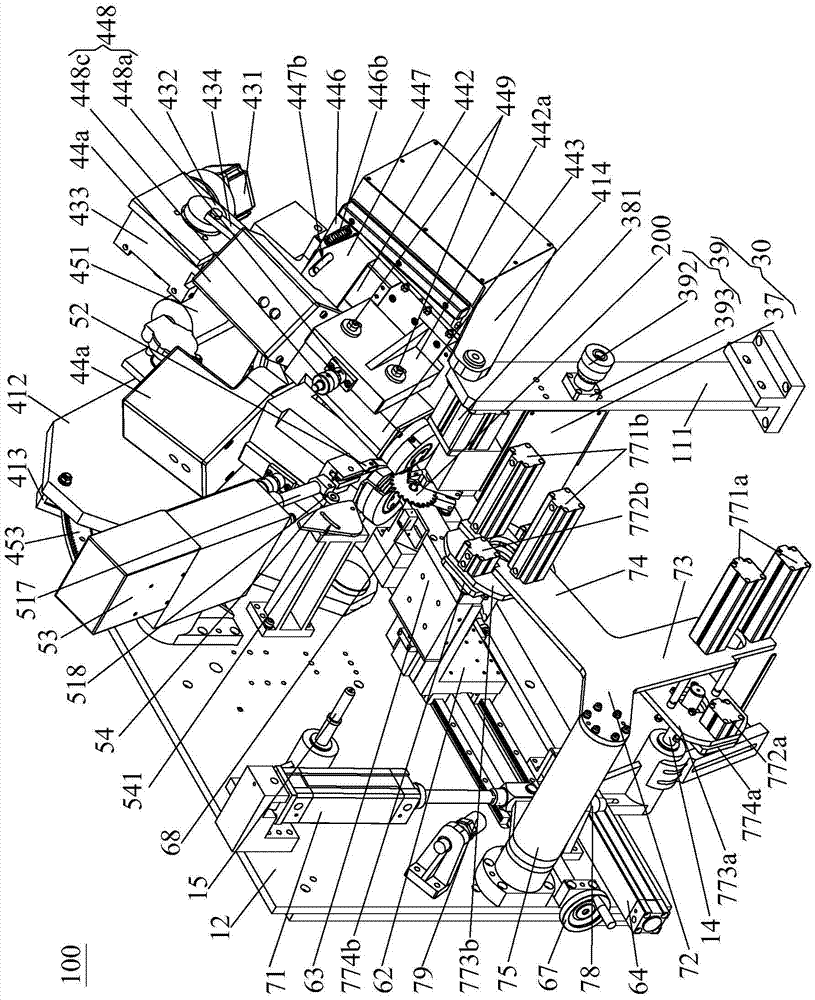

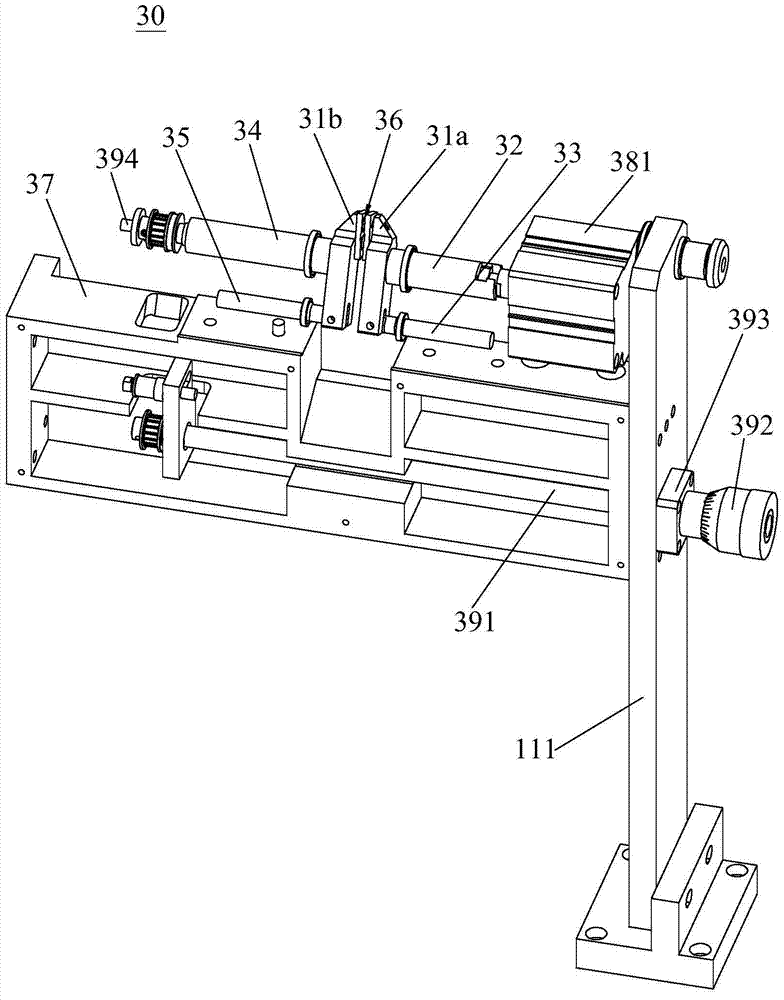

[0030] see Figure 1 to Figure 12 , the double-sided electrical discharge machining machine 100 of the present invention is suitable for performing electrical discharge machining on both sides of the alloy solder piece 201 on the saw blade 200, and the double-sided electrical discharge machining machine 100 of the present invention includes a frame 10, a controller 20, a clamping Device 30, discharge gear grinding device 40, gear shifting device 50, carrying device 60 and conveying device 70; in the present embodiment, frame 10 includes a horizontal base 11 arranged horizontally and a vertical frame body 12 arranged vertically, And the horizontal base 11 has a collection tank 13 for collecting surplus materials and waste materials produced in the processing proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com