Marble corner processing device

A processing device and marble technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of manual injury, high labor cost, difficult marble chamfering, etc., to reduce the difficulty of grinding and improve the pass rate. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is a further detailed description through specific embodiments:

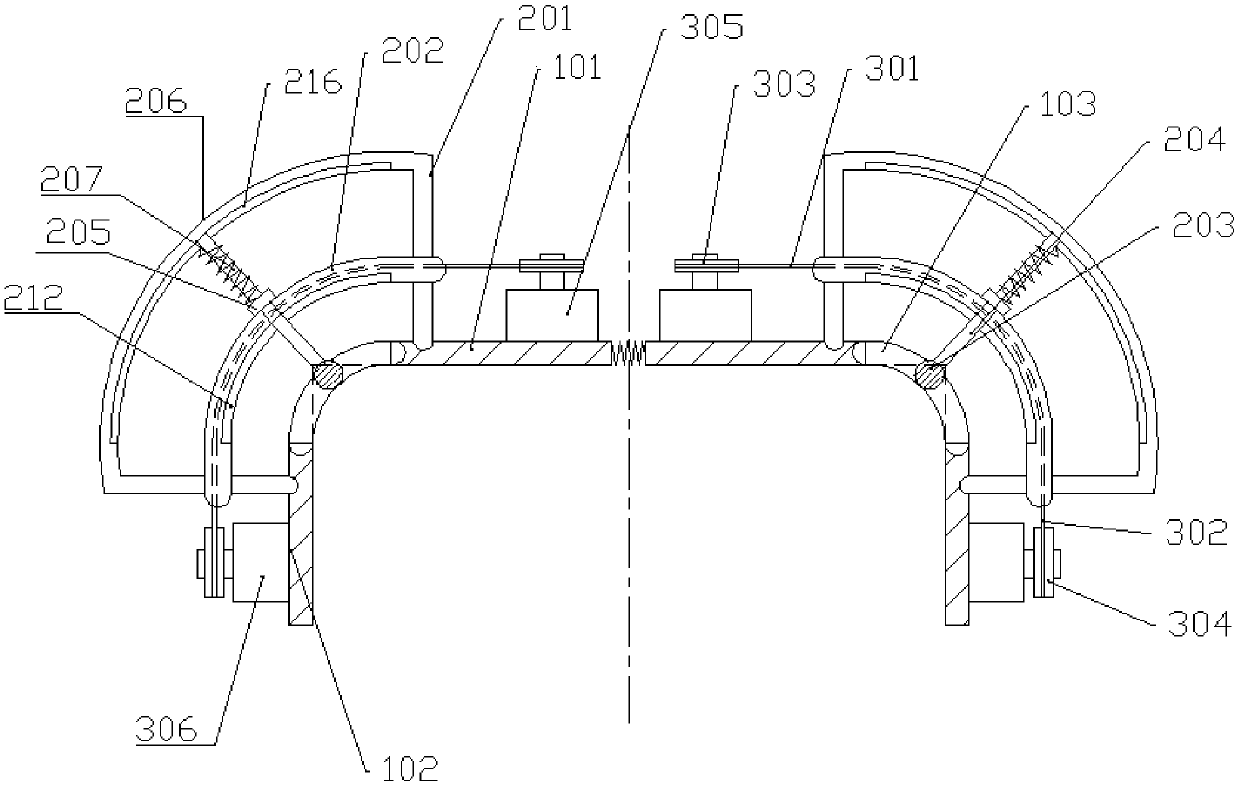

[0017] The reference signs in the accompanying drawings of the specification include: the first limiting plate 101, the second limiting plate 102, the arc bar 103, the support frame 201, the first arc bar 202, the strip groove 212, the grinding ball 203, the support Rod 204, limit block 205, second arc rod 206, groove 216, telescopic rod 207, first pull cord 301, second pull cord 302, first pulley 303, second pulley 304, first motor 305. A second electric motor 306.

[0018] The example is basically as attached figure 1 Shown: The marble edge processing device includes two limit mechanisms and two chamfering mechanisms, the chamfering mechanisms are installed on the limit mechanisms; and the two limit mechanisms are opposite to each other, and the two chamfering mechanisms are opposite to each other.

[0019] The limiting mechanism on the left side and the limiting mechanism on the right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com