Star ring type multi-perforated expansion clamping device

A clamping device and star ring technology, which is applied in the field of quick clamping devices, can solve the problems of tooling cylindrical hole size mismatch, part surface damage, large clearance, etc., to improve processing efficiency, improve processing accuracy, and reduce grinding difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

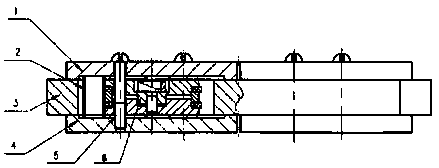

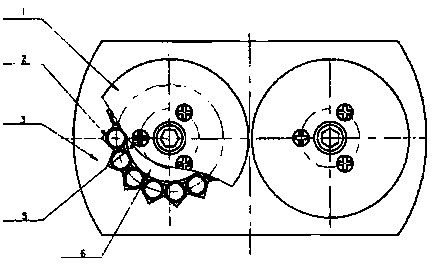

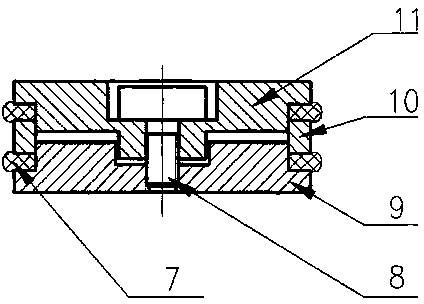

[0015] Such as figure 1 , figure 2 As shown, the star ring type multi-hole expansion clamping device includes a V-shaped groove star ring base frame 3, a circular expansion assembly 6, and the circular expansion assembly 6 is placed in the V-shaped groove star ring base frame 3, and the V-shaped groove star ring base frame 3 The ring base frame 3 is a flat plate, and there are two star rings in the plate, and each star ring is composed of 15 90° V-shaped grooves. The circular expansion assembly 6 is inserted into the V-shaped groove star ring, and the circular expansion assembly 6 can expand evenly in the radial direction, changing the distance between the V-shaped groove star ring and the circular expansion assembly 6 . Under the action of the axial force of the inner hexagon bolt 8, the circular expansion component 6 is continuously tightened so that the rubber ring 7 deforms evenly in the radial direction. The hollow tube workpiece 2 is radially clamped, and the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com