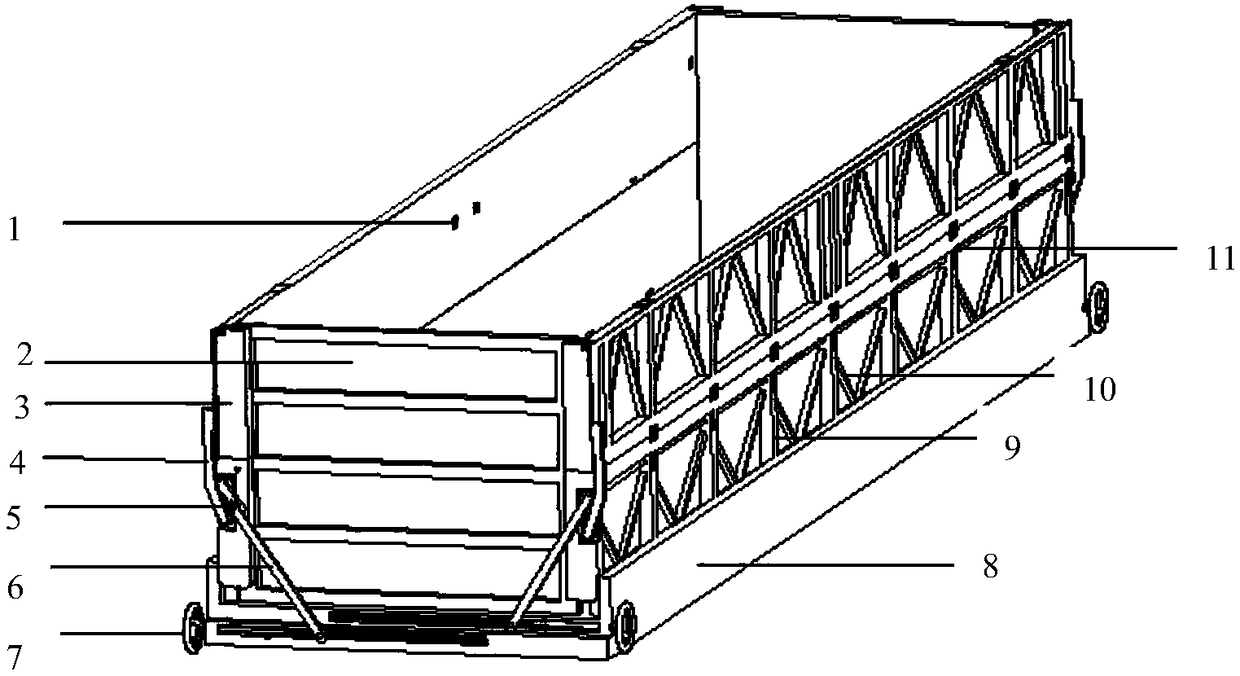

Universal rail flat-open wagon

A track and end wall technology, which is applied to trucks, transport passenger cars, railway car bodies, etc., can solve problems such as unsatisfactory demands, and achieve the effects of reducing the running rate of empty cars, increasing the substitution of vehicle types, and improving the efficiency of railway transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

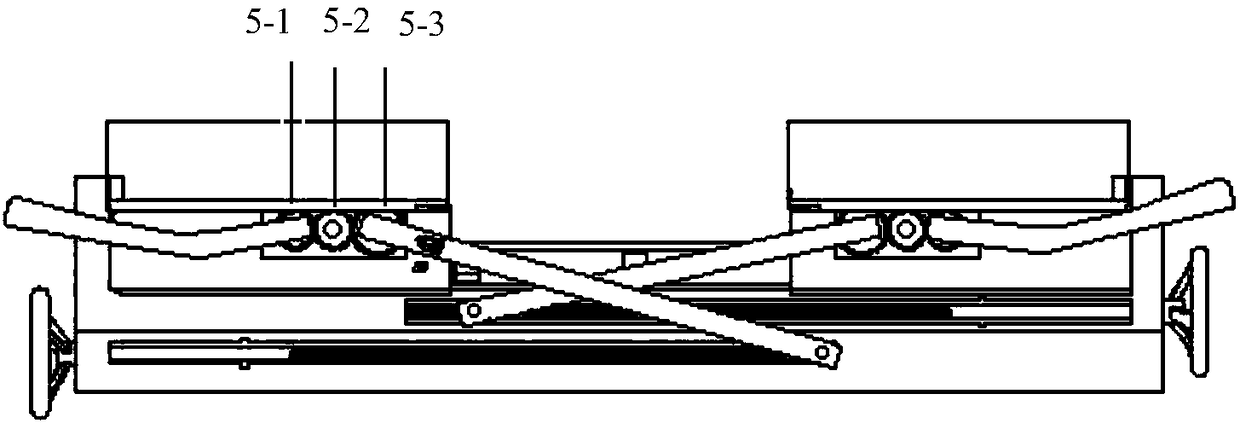

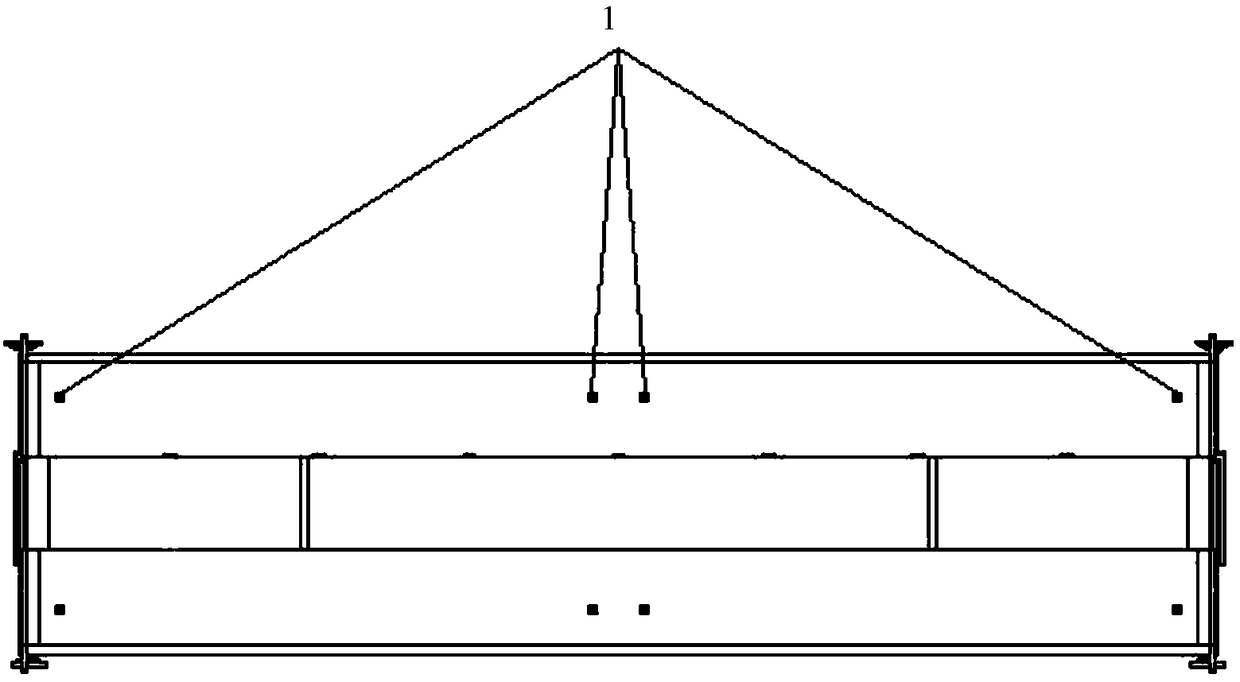

[0021] exist Figure 1 to Figure 11 In the schematic diagram of the present invention described above, the underframe 8 is a channel steel shell with an upper opening, and a lower side wall 9 is provided between the two side walls of the underframe, and the upper part of the lower side wall is formed by refolding and 3 movable connections on the upper side wall. On the outer wall of the upper side wall and the lower side wall, the diagonal brace 10 and the side column 11 are fixedly connected, and the upper side wall, the side column, the lower side wall and the diagonal brace form the side wall. The two ends of the two side walls are respectively connected by end walls 2 . A rotating shaft hole is provided on one side wall of the end wall, and a rotating shaft 18 is inserted in the rotating shaft hole 16, and the rotating shaft is connected to one of the side walls. An end wall lock hole 17 is arranged on the end wall, and the position of the lock hole on the end wall The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com