Straightening machine

A straightening machine and straightening technology, applied in the field of straightening machines, can solve the problem that there is no way to change the straightening speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

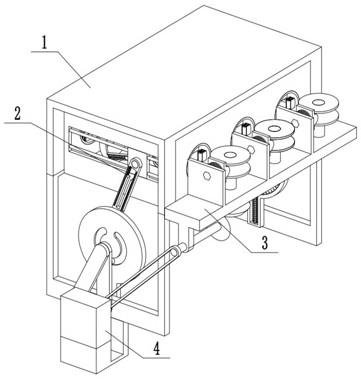

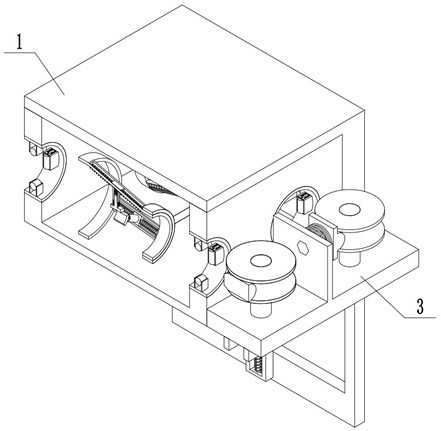

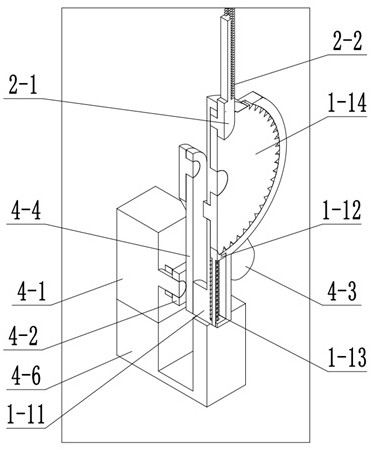

[0034] Combine below Figure 1-13 Describe this embodiment, a straightening machine, including a carrying assembly 1, a transmission assembly 2, a straightening assembly 3, a power assembly 4, the transmission assembly 2 is arranged on the width direction side of the carrying assembly 1, and the straightening assembly 3 is arranged behind the carrying assembly 1, and the power assembly 4 is arranged at the bottom of the width direction side of the carrying assembly 1, and the power assembly 4 is connected to the carrying assembly 1 through the transmission assembly 2, and is connected to the straightening assembly 3;

[0035]The carrying assembly 1 includes an outer frame 1-1, an upper end cover 1-2, a side wall sliding column 1-3, a side wall slider 1-4, an outer ring 1-5, a rectangular block 1-6, and a roller 1 -7, roller slider one 1-8, slider slider one 1-9, slider push spring one 1-10, swing rod 1-11, swing rod clamping rod 1-12, clamping rod push spring one 1- 13. Turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com