Anisotropic wound dressing and preparation method thereof

An anisotropic, wound-surface technology, applied in pharmaceutical formulations, pharmaceutical sciences, absorbent pads, etc., to achieve the effects of controllable size, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of anisotropic wound dressing, comprises the following steps:

[0028] S1. Mix and stir the dopamine solution, nanoparticle solution, Tris base and hydrochloric acid for 6 hours under light-shielding conditions, so that the surface of the polydopamine-wrapped nanoparticle is obtained to obtain a polydopamine-wrapped nanoparticle solution, and the polydopamine-wrapped nanoparticle The diameter is 200nm; the nanoparticles are selected from silica nanoparticles or titania nanoparticles;

[0029] S2, adding the solution prepared in S1 to ethanol, so that the polydopamine-wrapped nanoparticles are uniformly dispersed in ethanol;

[0030] S3. Use a spray gun to spray the liquid obtained in S2 on the surface of the dressing for 3-5 times to ensure uniform coating. After the ethanol volatilizes, put the dressing with the sprayed side up and place it in the cultured place together with the dichloromethane solution of fluorosila...

Embodiment 1

[0034] Preparation of anisotropic wound dressing:

[0035] (1) Superhydrophobic treatment:

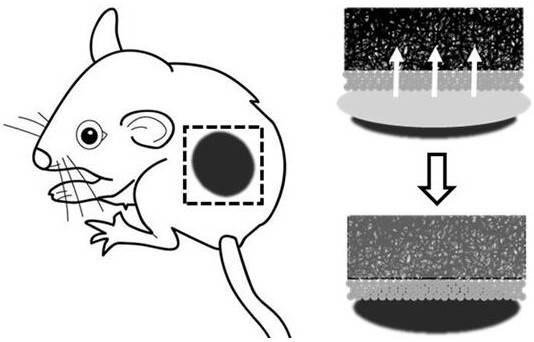

[0036] Mix 1.5 mL of dopamine solution (13.3 mg / mL), 2.03 mL of silica nano-solution (0.1 g / mL), 5 mL of Tris base (0.1 mol / L) and 1.47 mL of HCl (0.1 mol / L) into a glass bottle Stir in medium for 6 hours, so that polydopamine wraps the surface of silica nanoparticles. The obtained polydopamine-wrapped silica nanoparticles are evenly dispersed in ethanol, and sprayed repeatedly on the surface of polyurethane sponge with a spray gun for 3-5 times. Place them together in a petri dish, seal them with a parafilm, place them in an oven at 70 degrees Celsius, and the evaporation process lasts for 12 hours. like figure 1 As shown, a superhydrophobic surface is obtained.

[0037] (2) Super hydrophilic treatment:

[0038] In the case of protecting the superhydrophobic surface prepared in step (1), the rest of the dressing was treated with oxygen plasma for 15 minutes to make it superhydrop...

Embodiment 2

[0040] Preparation of anisotropic wound dressing:

[0041] (1) Superhydrophobic treatment:

[0042] Mix 1.5 mL of dopamine solution (13.3 mg / mL), 2.03 mL of silica nano-solution (0.1 g / mL), 5 mL of Tris base (0.1 mol / L) and 1.47 mL of HCl (0.1 mol / L) into a glass bottle Stir in medium for 6 hours, so that polydopamine wraps the surface of silica nanoparticles. Evenly disperse the obtained nanoparticles in ethanol, and use a spray gun to spray repeatedly on the surface of the chitosan sponge for 3-5 times. After the ethanol volatilizes, place the sprayed side upwards and place it on a petri dish together with the dichloromethane solution of fluorosilane , sealed with a parafilm, placed in an oven at 70 degrees Celsius, and the evaporation process lasted for 12 hours to obtain a superhydrophobic surface.

[0043] (2) Super hydrophilic treatment:

[0044] In the case of protecting the superhydrophobic surface prepared in step (1), the rest of the dressing was treated with oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com