A method to limit the one-way transport of droplets in digital microfluidic chips

A digital microfluidic and droplet technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of droplet misalignment, increased chip complexity and cost, increased chip stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is by no means limited to the described embodiments.

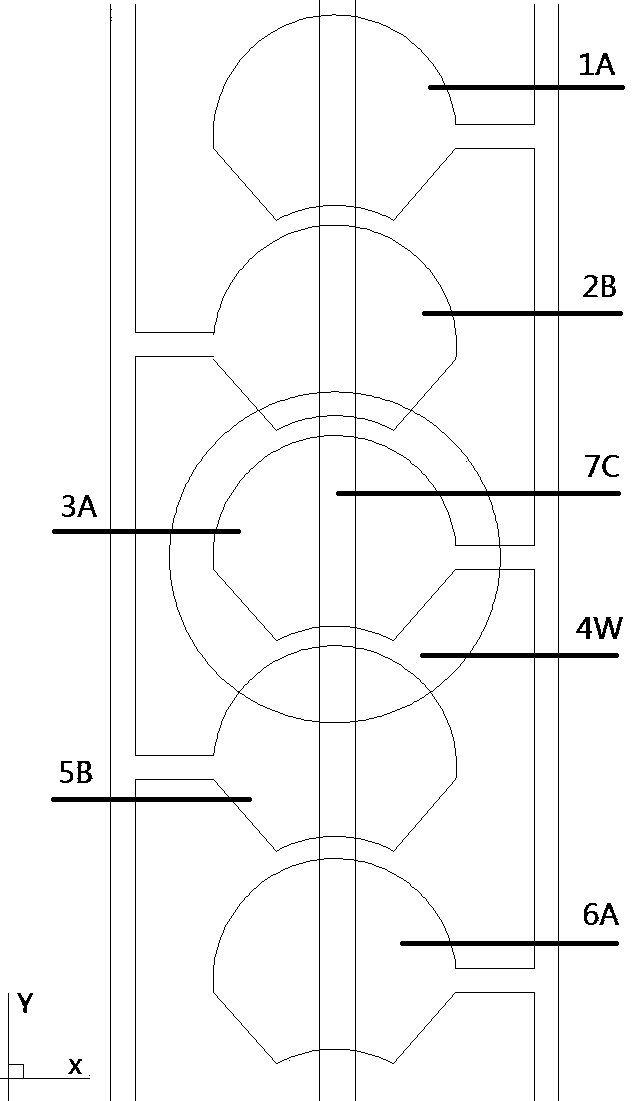

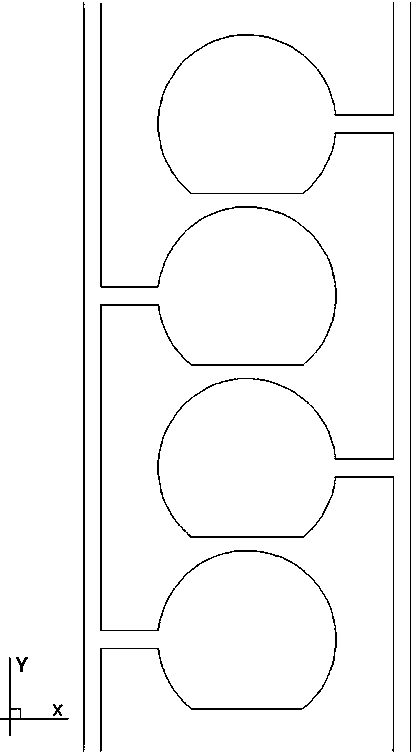

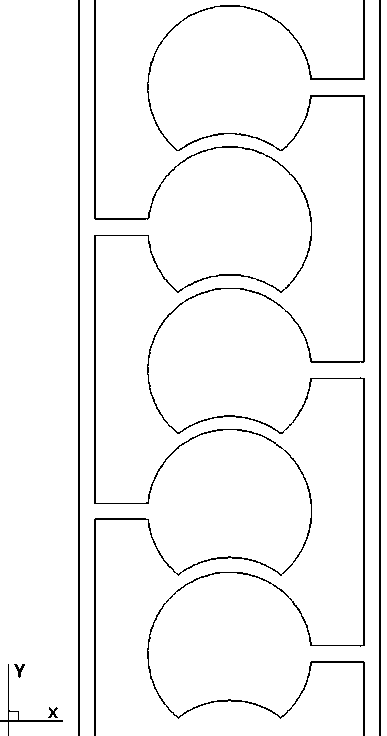

[0035] The chip is composed of the upper plate, the lower plate and the liquid droplets sandwiched between the upper and lower plates (refer to the patent, the application number is 200810038582.7 figure 1 shown). The two groups of driving electrodes A and B and their connections are in the same plane of the lower plate of the chip. The electrodes are insulated by a dielectric layer, and the electrodes and droplets are separated by a dielectric layer and a hydrophobic layer; the upper plate contains a whole electrode, called This electrode is a secondary electrode, which is directly grounded and separated from the droplet by a dielectric layer and a hydrophobic layer. figure 1 It is a structural schematic diagram of the electrode configuration of the present invention, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com