Ship rail carrying device

A carrier device and track technology, applied in transportation and packaging, loading/unloading, ships, etc., can solve the problems of increased weight, high cost, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

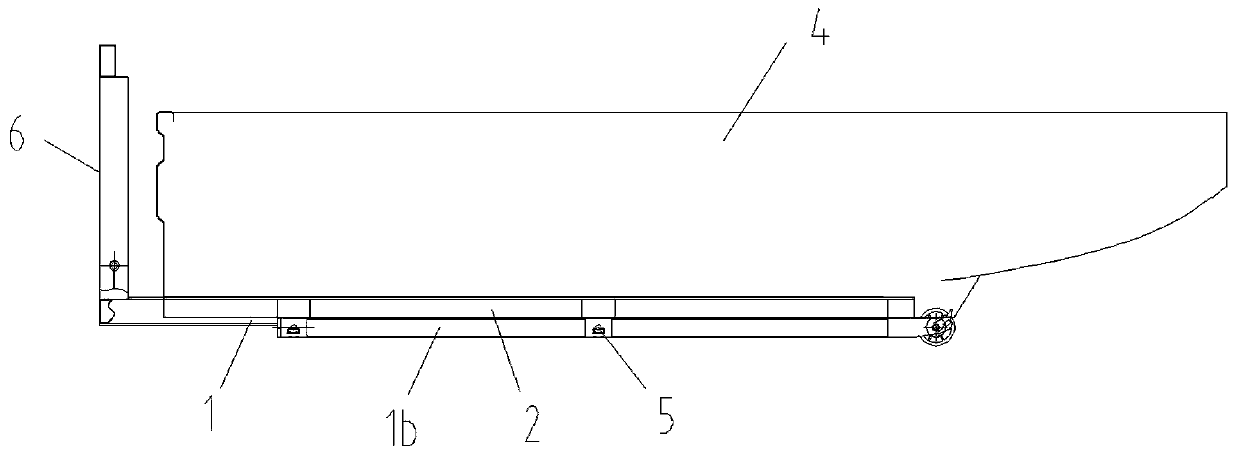

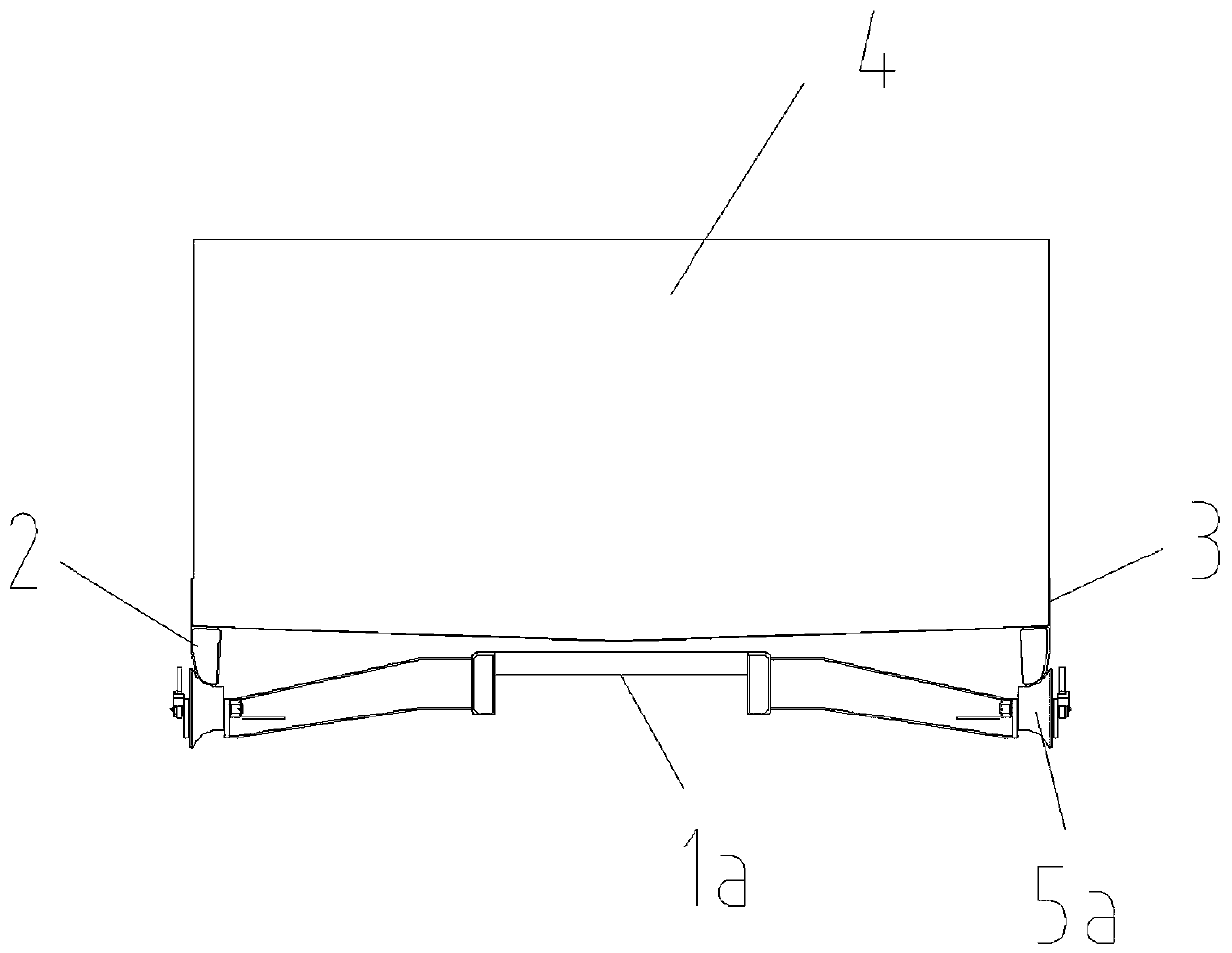

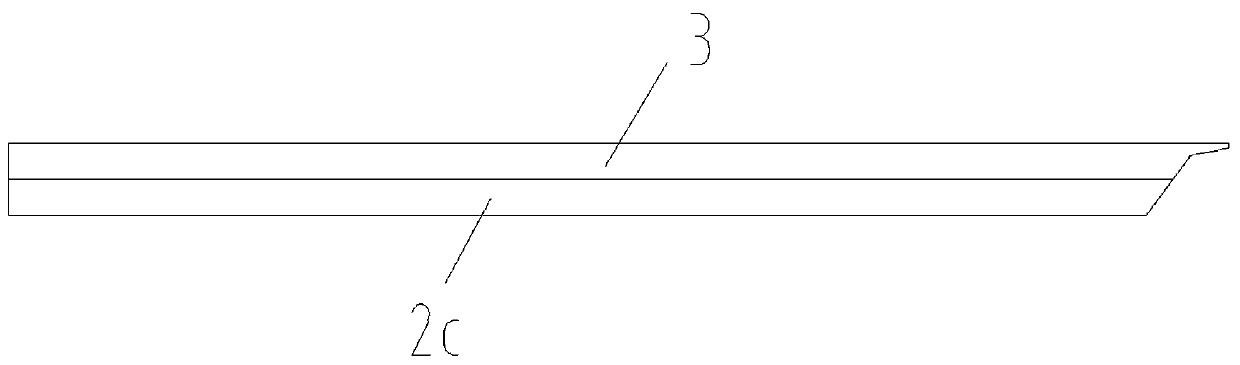

[0015] to combine Figure 1~4 As shown, the present invention provides a ship rail carrying device, including a carrying platform 1 and two rails 2; each roller table includes a hollow bar-shaped rail body, and the cross section of the rail body is in the shape of a right-angled fan. The rail of this embodiment The main body is composed of a horizontal plate 2a, a vertical plate 2b and an arc-shaped plate 2c; 2a and the arc-shaped plate 2c; the two rollers 2 are symmetrically fixed on both sides of the bottom of the ship 4 through the connecting plate 3;

[0016] Both sides of carrying platform 1 are respectively provided with roller group 5; As preferably, carrying platform 1 comprises the arched frame 1a that a group of parallel intervals are arranged, and the two ends of arched frame 1a are respectively provided with roller 5a, and between arched frame 1a The space is fixedly connected by a beam 1b, so that a group of rollers on each side forms a roller group. The arc sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com