Automatic guide rail carrying device and robot cooperative carrying method and system

A technology for mobile robots and robots, applied in machine learning, control/regulation systems, instruments, etc., to solve problems such as failure of transportation tasks, reduction of transportation efficiency, and inability of robots to continue working.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

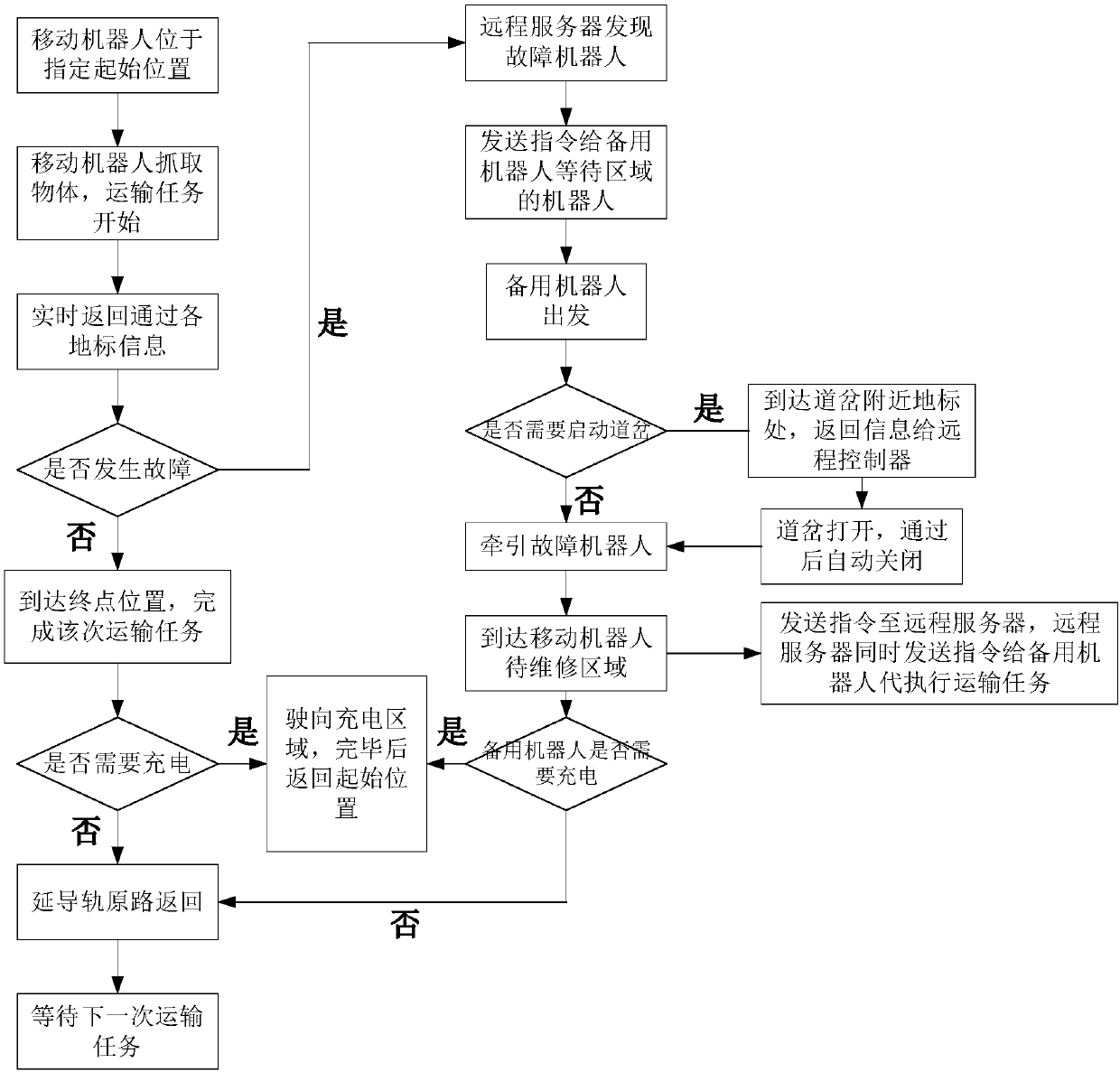

[0084] like figure 1 As shown, an automatic guide rail carrying device and a robot cooperative carrying method, comprising the following steps:

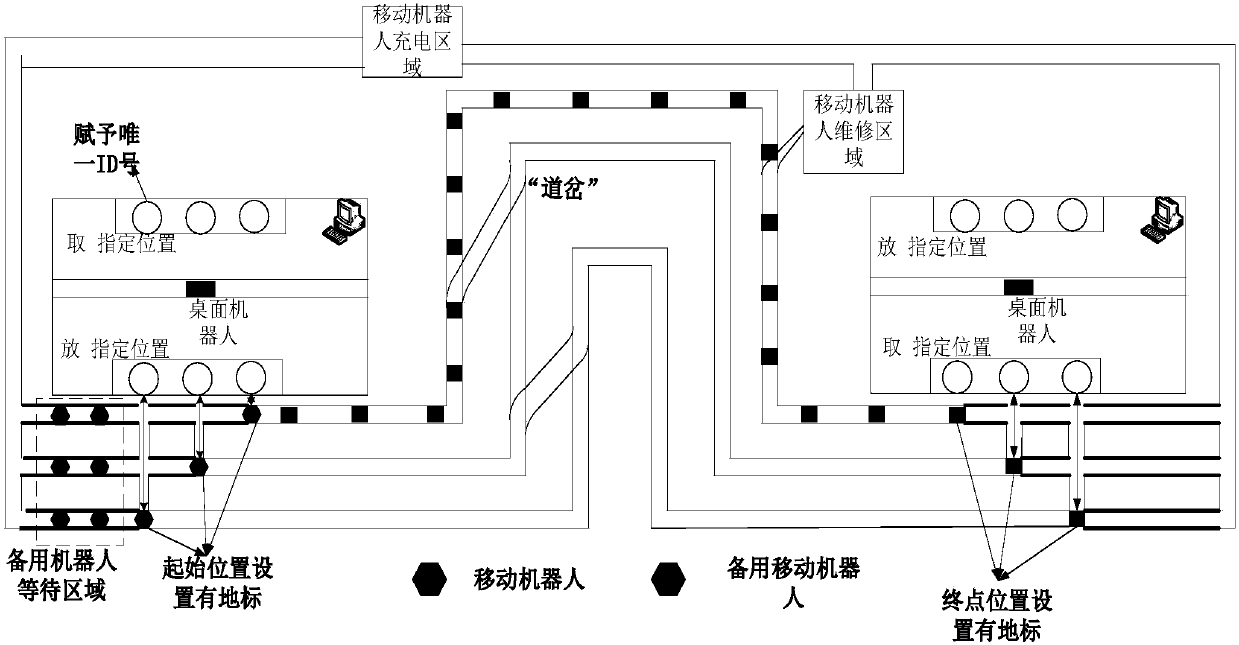

[0085] Step 1: Set up a ground guide rail between the workbenches where the starting point and end point of the transportation are located, set up a desktop guideway on the workbench, a designated pick-up location, a temporary pick-up location, and a designated place to put the object, and use the remote controller to send the pick-up instruction;

[0086] Use the remote controller to send fetching instructions to the mobile robot and the desktop controller, so that the mobile robot moves to the fetching workbench, and the desktop robot moves to the designated pick-up position to start the fetching task;

[0087] The desktop guide rail is arranged in the middle of the workbench, and the designated pick-up po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com