Device for fixing size of opening by screening and distributing almonds

A technology of opening size and sieving material, applied in sieving, grading, solid separation, etc., can solve the problems of almonds that cannot be tasted, the shell is damaged, and the quality of products is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

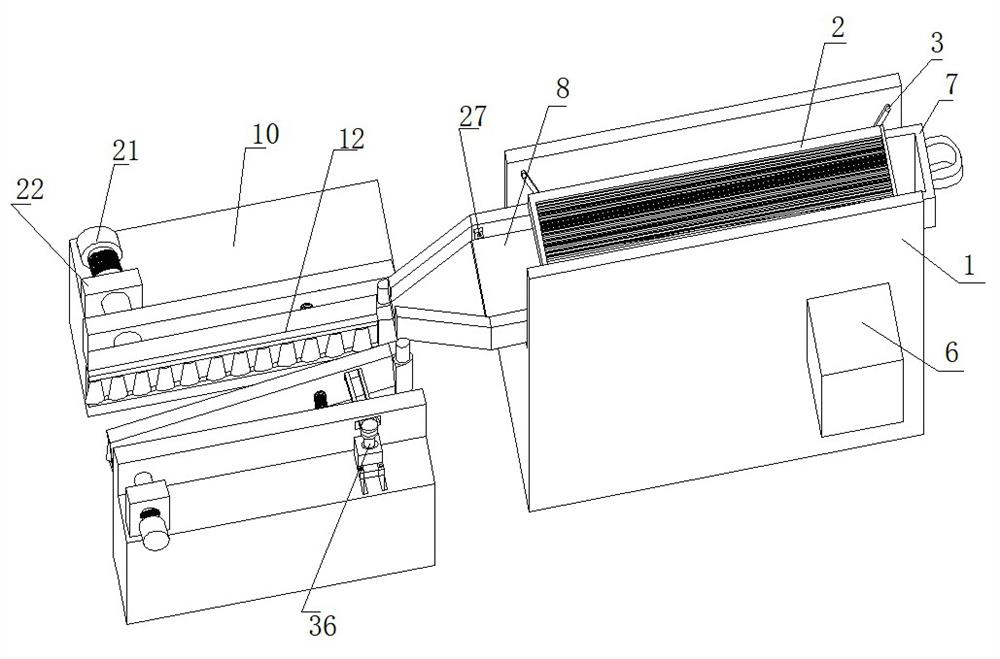

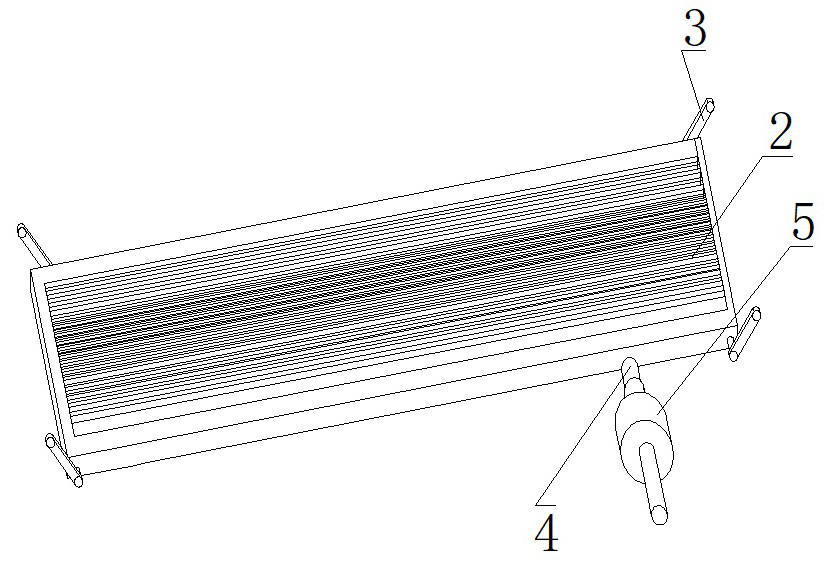

[0034] Such as Figure 1-12 As shown, a kind of almond wood sieve material is divided into a device to fix the size of the opening, including a sieve machine base 1 and a sieve frame 2

[0035] By adopting the above-mentioned technical scheme: at least one sliding bearing seat is provided on the inner side walls of the two sides of the sieve material frame 1, and the four corners of the sieve material frame 2 are movably installed with connecting rods 3, and one end of the connecting rod 3 is connected to the The sieving frame 2 is movably connected, the other end of the connecting rod 3 is connected to the sliding bearing seat, and one end of the sieving frame 2 is provided with a jolting shaft 4, and the jolting shaft 4 is fixedly mounted on the eccentric of the eccentric wheel 5. On the shaft, the eccentric wheel 5 is fixedly installed on the vibrating screen motor 6, the motor of the vibrating screen motor 6 is installed on the motor base of the sieve material base 1, and ...

Embodiment 2

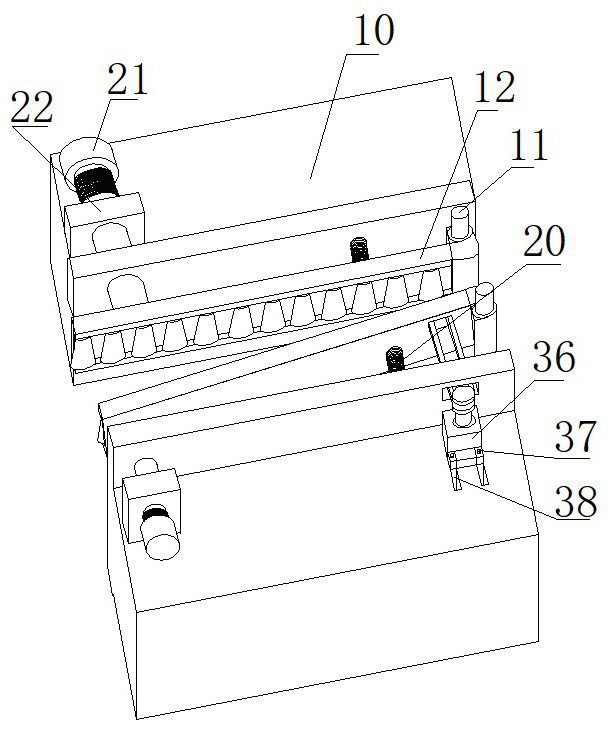

[0038] Such as Figure 1-12 Shown, a kind of almond sieve material divides the device that opening size is fixed, comprises discharge frame 8.

[0039] By adopting the above technical scheme: the discharge end of the discharge frame 8 is provided with two material distribution seats 10, and the inner side walls of the material distribution seats 10 on both sides are provided with shaft wall rods 11, and the shaft wall rods 11 are connected with the distribution boards. One end of the material rod 12 is movably connected, and the bottom of the other end of the material distribution rod 12 is provided with a pulley 13, and the pulley 13 is movably installed on a pulley seat 14, and the pulley seat 14 is fixedly installed on the inner side of the material distribution seat 10 The inner side of the material distribution rod 12 on both sides is provided with at least one inclined roller mounting seat 15, the inclined roller mounting seat 15 is equipped with an inclined roller 16, a...

Embodiment 3

[0042] Such as Figure 1-12 Shown, a kind of almond sieve material divides the device that opening size is fixed, comprises material storage sliding cylinder 23.

[0043] By adopting the above technical scheme: the storage slide 23 is provided with a blanking cylinder 29, and the storage slide 23 is fixedly installed on the inner wall of the distribution seat 10 through a fixing member 25, and the blanking cylinder 29 The piston rod is provided with a material distribution cushion 30, and the material discharge cylinder 29 is electrically connected with the encoder.

[0044] Gap blanking device, a photoelectric sensor switch is arranged between the first cutting part 17 and the second cutting part 18. When the photoelectric sensor switch does not sense the almond, the blanking cylinder 29 is triggered to open. When the photoelectric sensor switch When the switch sensed the almond, the blanking cylinder 29 was triggered to close, and the gap feeding was completed.

[0045] It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com