Taking device for oven and glass cup production line adopting taking device

A technology of a reclaiming device and an oven, which is applied in the process of producing decorative surface effects, decorative arts and other directions, can solve problems such as worker burns, low glass production efficiency, etc., to avoid burns and improve feeding and discharging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

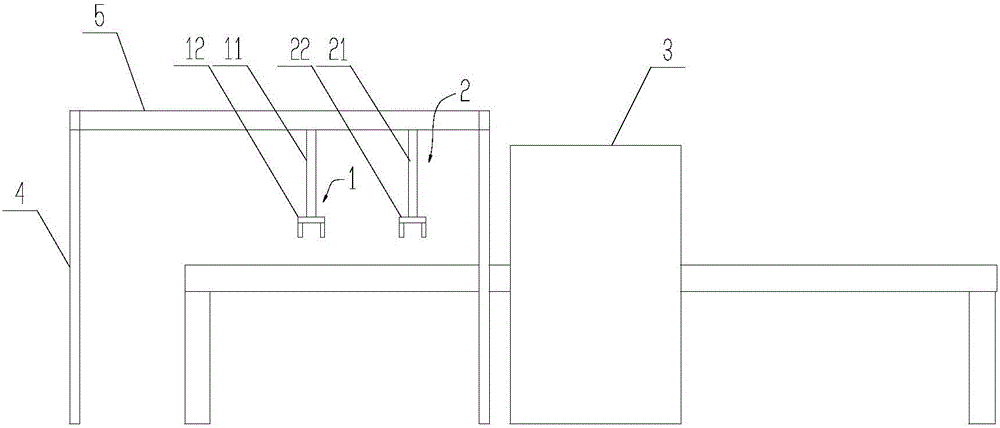

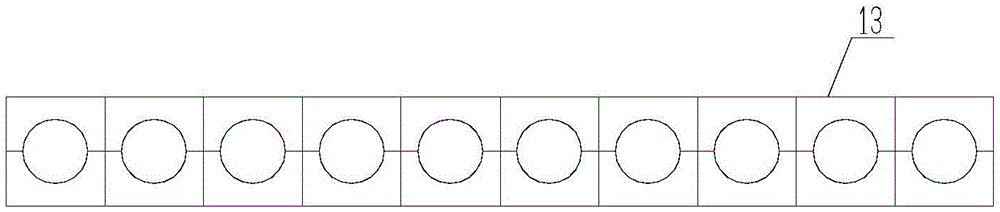

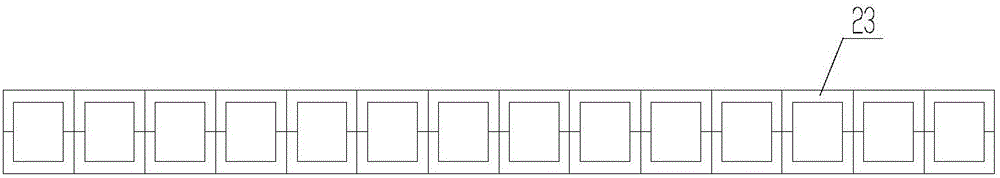

[0026] Such as Figure 1 to Figure 3 As shown, the present embodiment provides an oven retrieving device, the oven retrieving device includes a manipulator 1 for holding cups and a manipulator 2 for holding tiles, and the feed conveyor belt and the discharge conveyor belt of the oven 3 are provided with Manipulator 1 for holding cups and Manipulator 2 for holding tiles.

[0027] Through the setting of the cup manipulator 1 and the ceramic chip manipulator 2, the mechanized feeding and discharging of the oven 3 can be realized, thereby improving the feeding and discharging efficiency of the oven 3 and avoiding manual operation. Burn problem.

[0028] The oven retrieving device also includes a support 4 and a crossbeam 5 arranged on the support 4 , and the crossbeam 5 is arranged parallel to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com