Fixed bed reactor used for low-temperature continuous pyrolysis treatment of waste circuit boards, and method thereof

A waste circuit board and reactor technology, applied in the direction of indirect heating dry distillation, special form dry distillation, educts, etc., can solve the problems of reducing the processing capacity and efficiency of the device, unable to realize continuous feeding and discharging, increasing the failure rate, etc., to improve energy Efficiency and economic benefits, great development advantages and application prospects, the effect of continuous feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106] Two kinds of waste circuit board raw materials are obtained in Beijing area (see Table 1 for the analysis data of waste circuit boards). The two raw materials of waste circuit boards are labeled 1 and 2 respectively. The waste circuit board 1 and the waste circuit board 2 were continuously processed in a fixed bed reactor, and the data results of two sets of pyrolysis products were obtained (see Table 2).

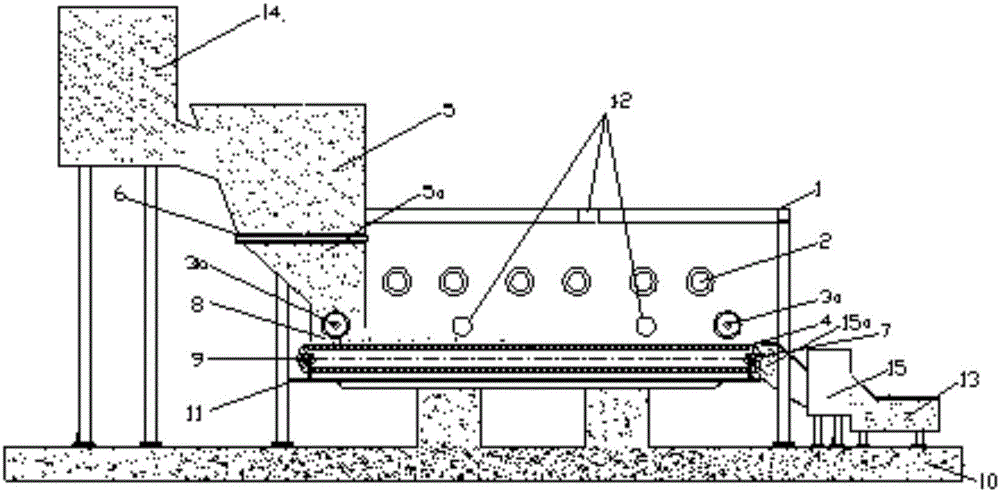

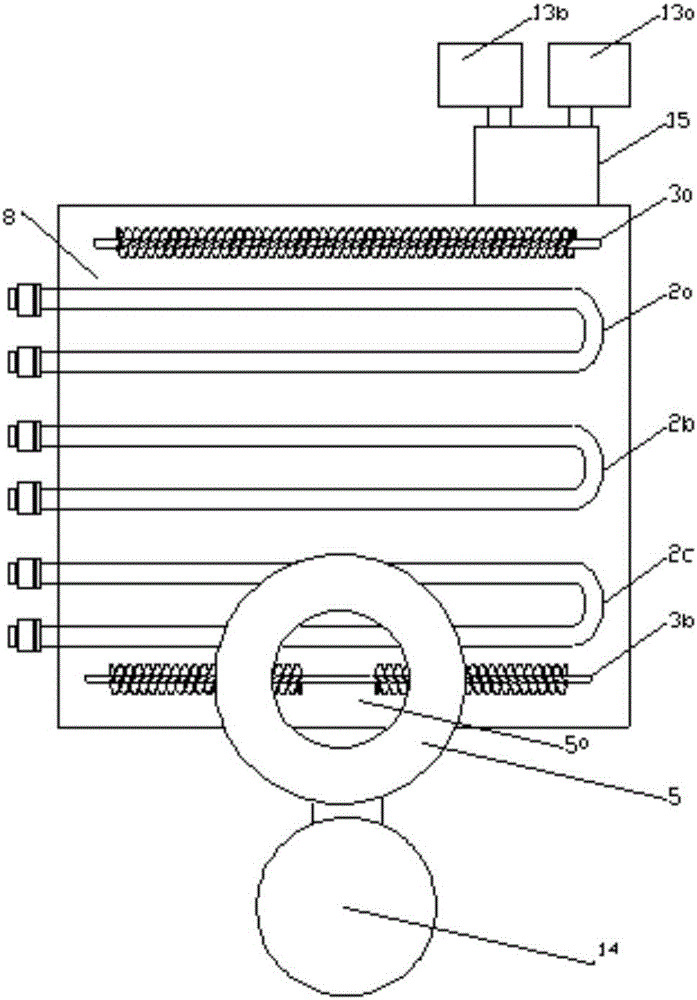

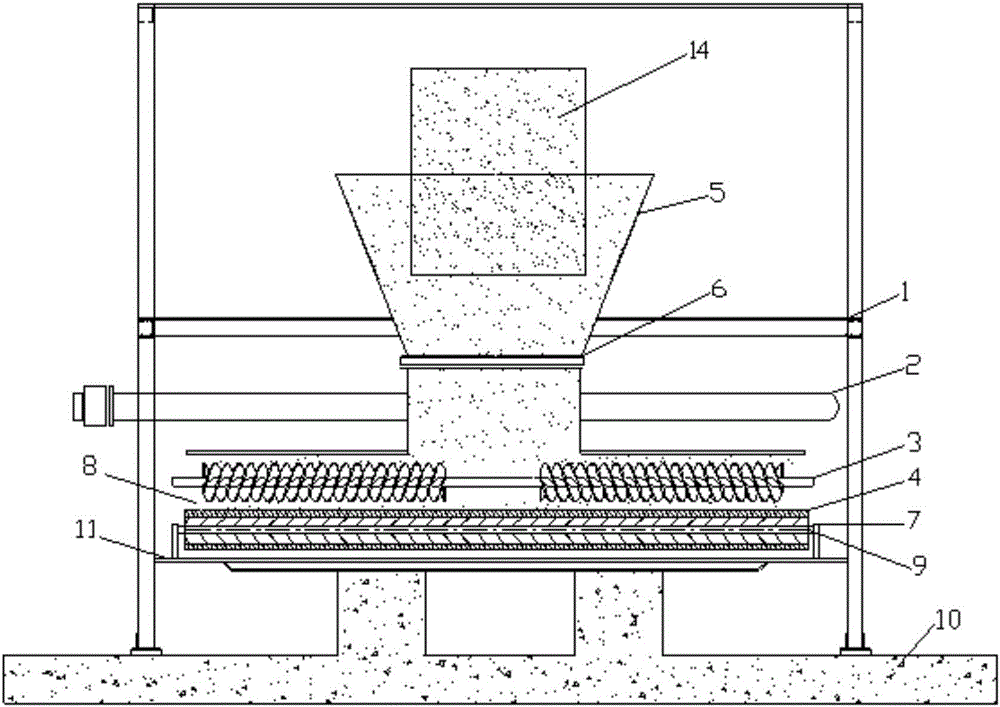

[0107] Firstly, the massive waste circuit board 1 is coarsely crushed and finely crushed by the two-stage shredder 14 , and the crushed waste circuit board 1 particles are stored in the feeding bin 5 . The gate valve 6 is opened, and the particles of the waste circuit board 1 enter the reaction chamber 8 from the discharge chute at the gate valve 6 under the action of gravity.

[0108] Driven by the feeding screw 3b and the transmission bearing 9, the material is evenly distributed on the material plate 4, and moves forward horizontally towards the discharge end. Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com