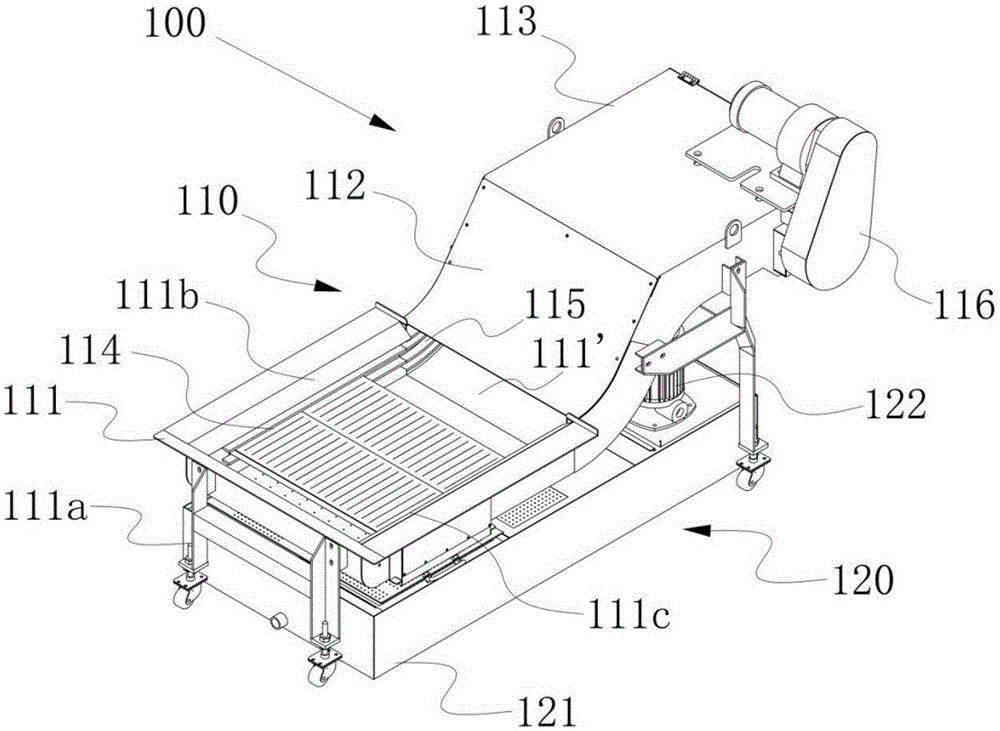

Cooling liquid recovery device integrating chip removal and circulation

A recovery device and cooling fluid technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of low cleaning efficiency of metal debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

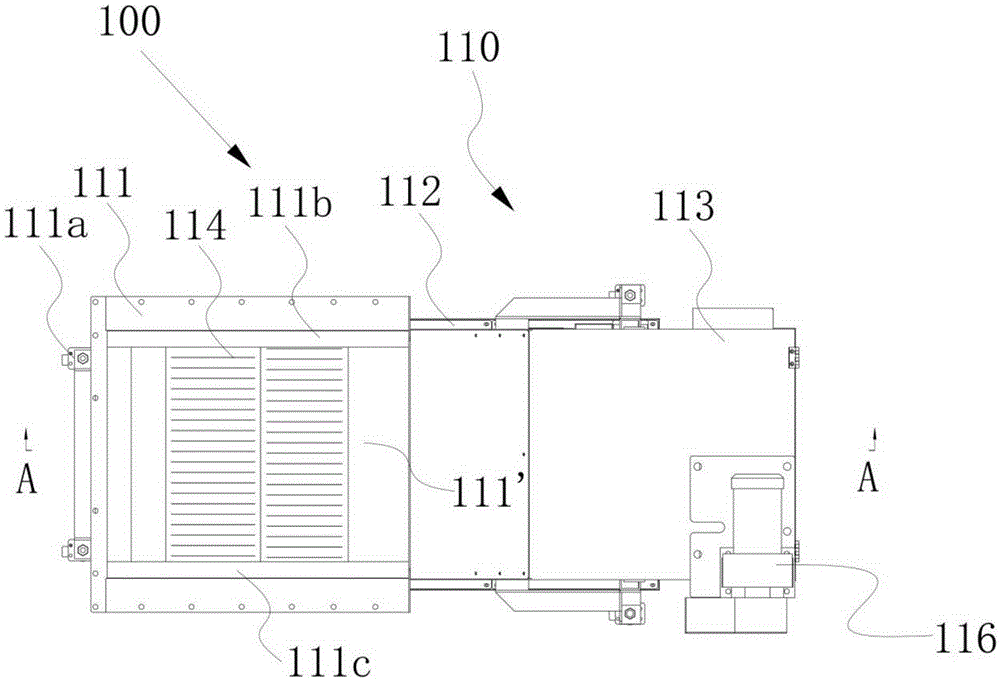

Embodiment approach

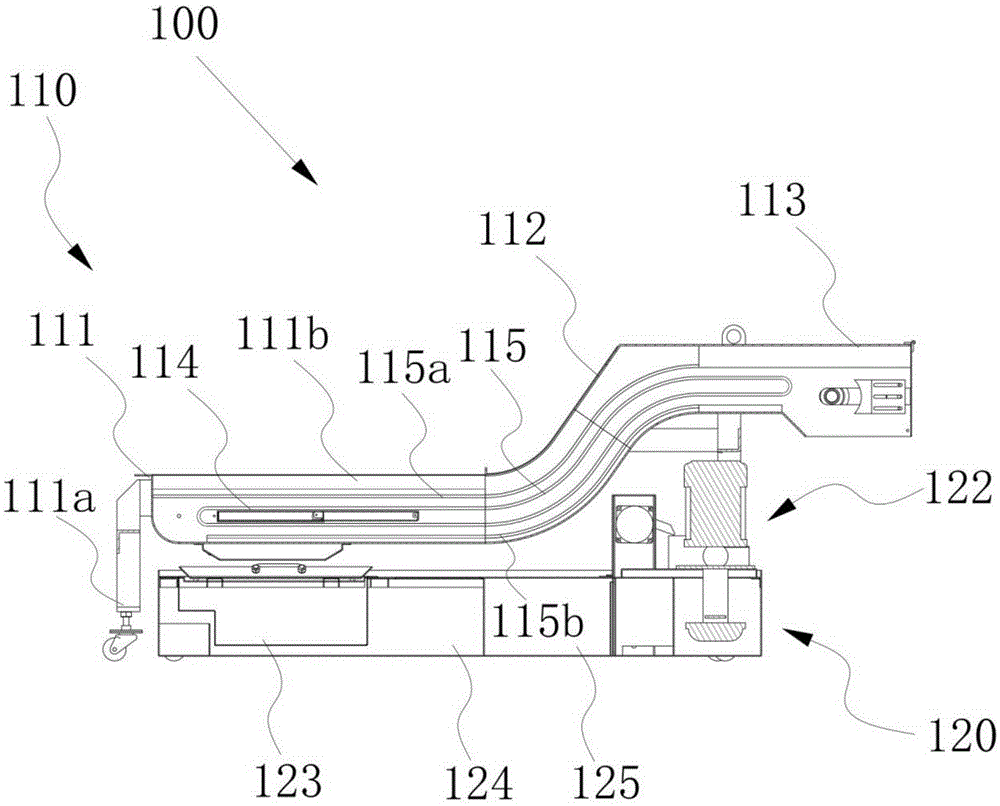

[0027] refer to Figure 4 The top of the coarse filter chamber 123 is covered with a coarse filter chamber cover plate with some water inlet holes, the top of the fine filter chamber 124 is covered with a fine filter chamber cover plate with some overflow holes, and the top of the cooling chamber 125 is provided with a circulating water pump 120 . As an implementation manner, the overflow hole is disposed on one side close to the coarse filtration chamber 123 .

[0028] Working principle: After the cooling dirty liquid mixed with metal debris is introduced from the opening 111' of the horizontal section 111, after the initial filtration by the primary filter plate 114, the metal debris with a larger geometric size remains on the surface of the primary filter plate 114 , and the cooling dirty liquid is discharged into the coarse filter chamber 123 of the coolant recovery box 120 located directly below the chip conveyor 110 through the drainage hole below the primary filter pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com