A dual track scraper assembly

A scraper and component technology, applied in the field of double-track scraper components, can solve the problems of low scraping and cleaning efficiency, complicated and inconvenient installation and disassembly, poor overall structure, etc., and achieves the effect of clean scraping effect, convenient and quick installation and disassembly, and not easy to wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

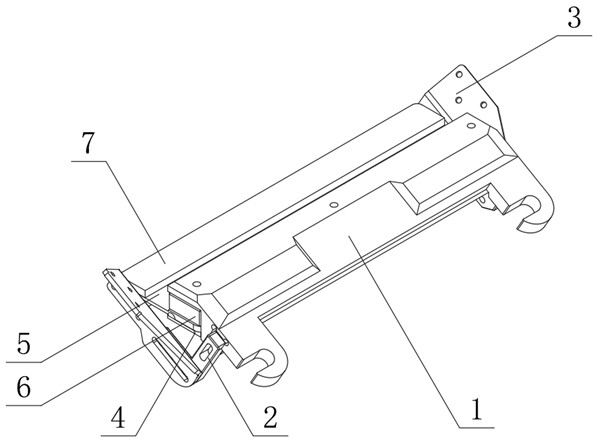

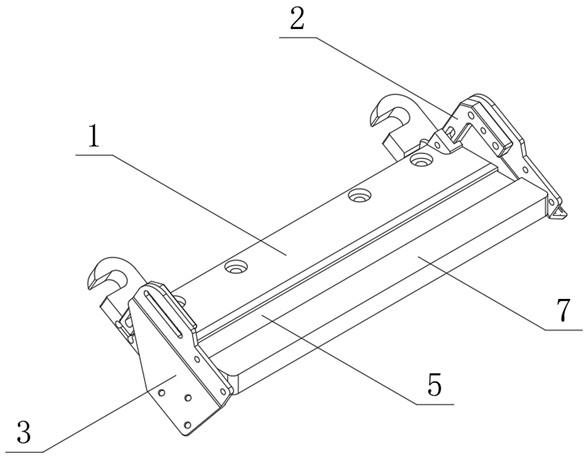

[0019] As an embodiment of the present invention, one end face of the scraper body 1 is provided with two hooks, and the scraper body 1 can be easily hooked and installed through the hooks.

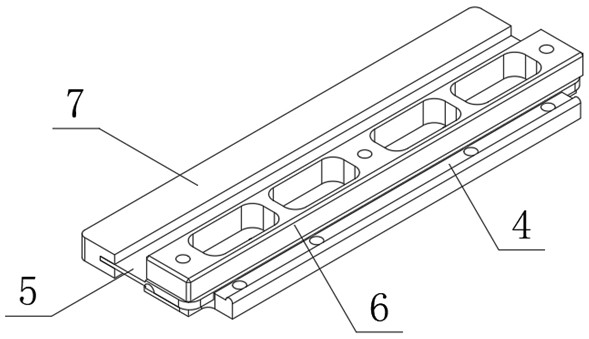

[0020] As an embodiment of the present invention, an installation slot is opened in the center of the end face of the scraper 7, and the other end of the glass fiber scraper 5 is inserted and installed inside the installation slot, so that the scraper 7 can be easily installed on the glass fiber The outer side of the scraper 5 is easy to install and disassemble, which greatly improves the convenience of use.

[0021] As an embodiment of the present invention, an arc-shaped clip is provided on the top end face of the cover plate 4, and an arc-shaped clip slot is provided on the bottom end face of the glass fiber scraper 5, and the arc-shaped clip is clamped and installed on the Inside the arc-shaped card slot, the glass fiber scraper 5 can be installed on the top of the cover plate 4 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com