Freezers

A technology for freezing devices and heat-insulating boxes, which is applied to household refrigeration devices, coolers, lighting and heating equipment, etc., which can solve the problems of excessive material consumption, poor non-adhesiveness, and increased production costs, so as to reduce the use cost and manufacture The effect of low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

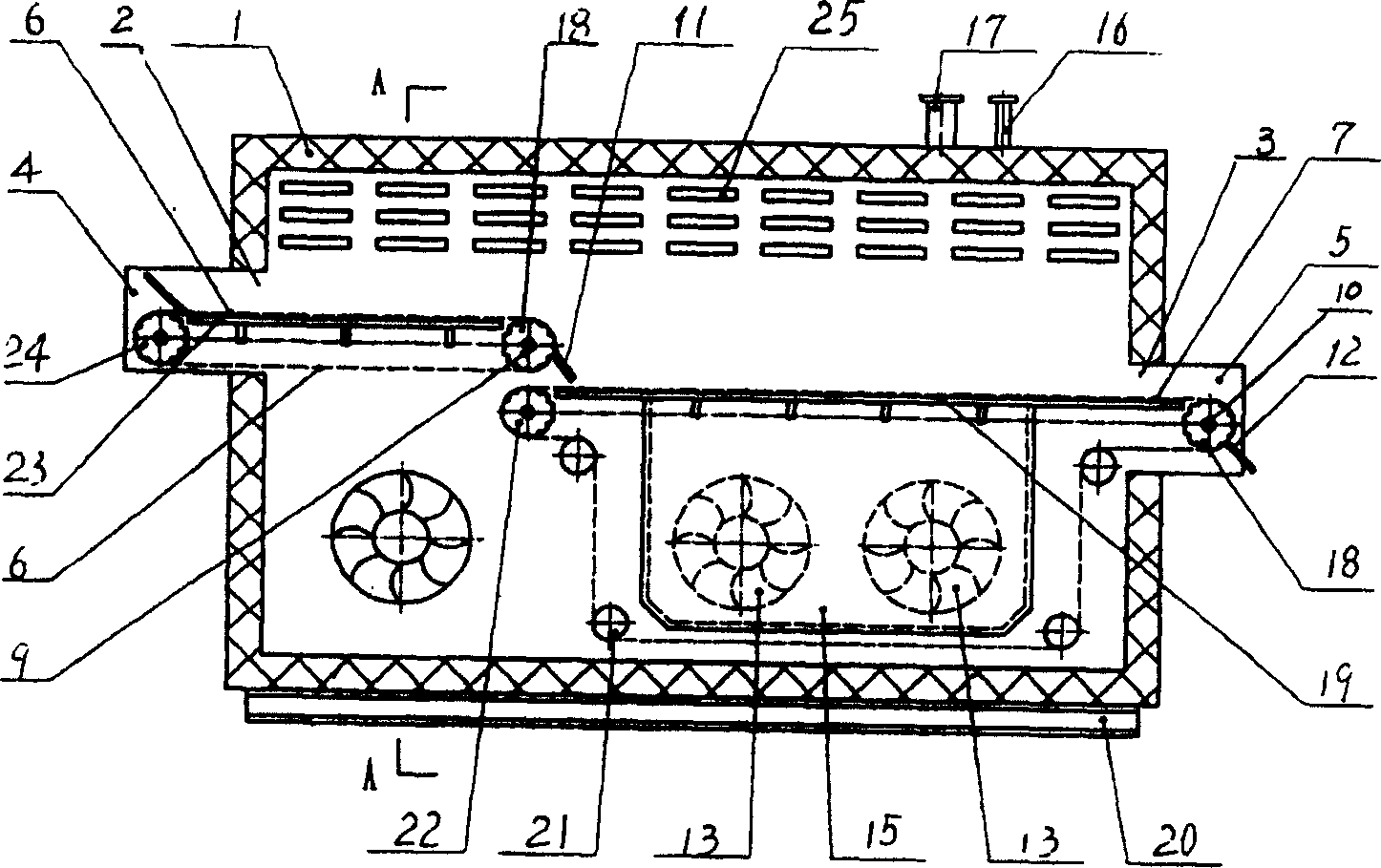

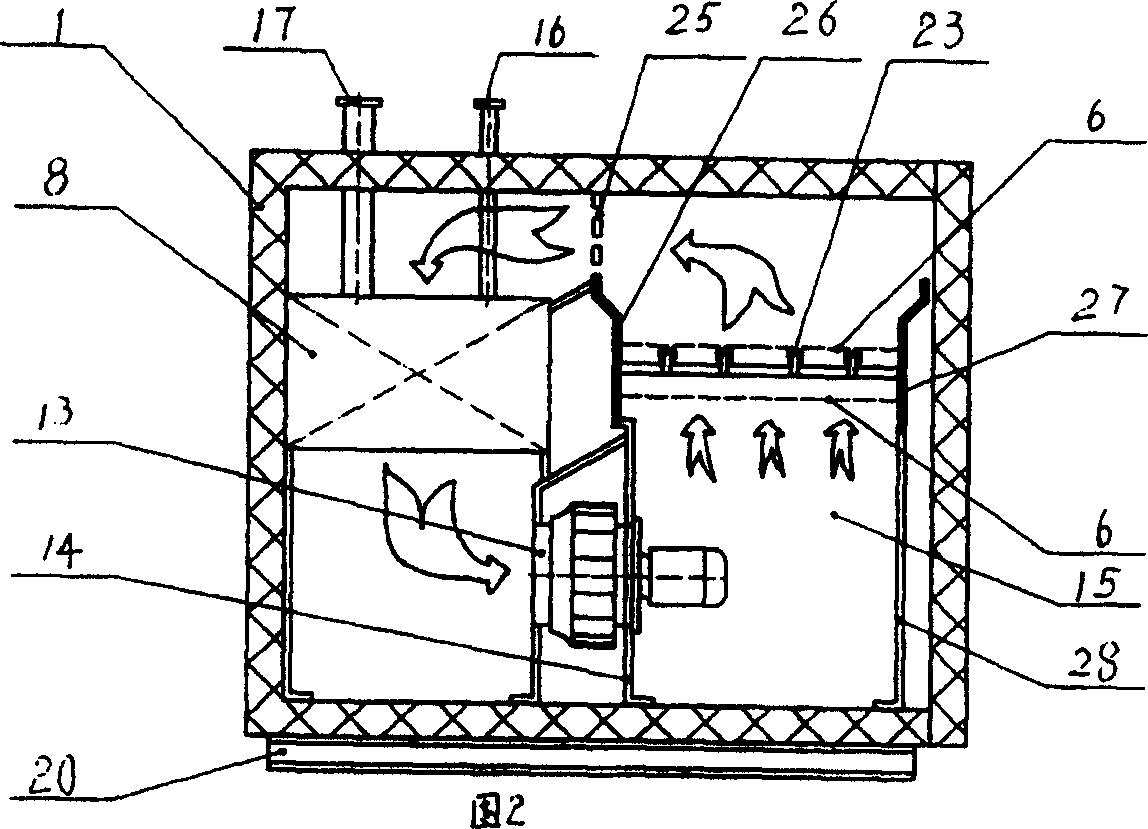

[0026] freezer (see figure 1 ) includes a heat-insulating box body 1, a feed frame 4 and a material-out frame 5 respectively placed in the material inlet 2 and the material outlet 3 of the heat-insulated box body, the first section of circulating conveying mesh belt 6 installed in the heat-insulated box body and the second section The second section of circulating conveying mesh belt 7, the evaporator 8 (seeing Fig. 2 ) positioned at circulating conveying mesh belt 6 and 7 sides, the scraper plates 11 and 12 respectively installed in circulating conveying mesh belt driving wheel shaft 9 and 10 places, respectively The air cooler 13 and the return air passage 25 installed below and above between the evaporator 8 and the circulating conveying mesh belt 6 and 7, the fan frame 14 for the air cooler is connected with the heat-insulating box, and the air outlet of the air cooler is connected with the circulating conveying network The air collection chamber 15 below the belt is conne...

Embodiment 2

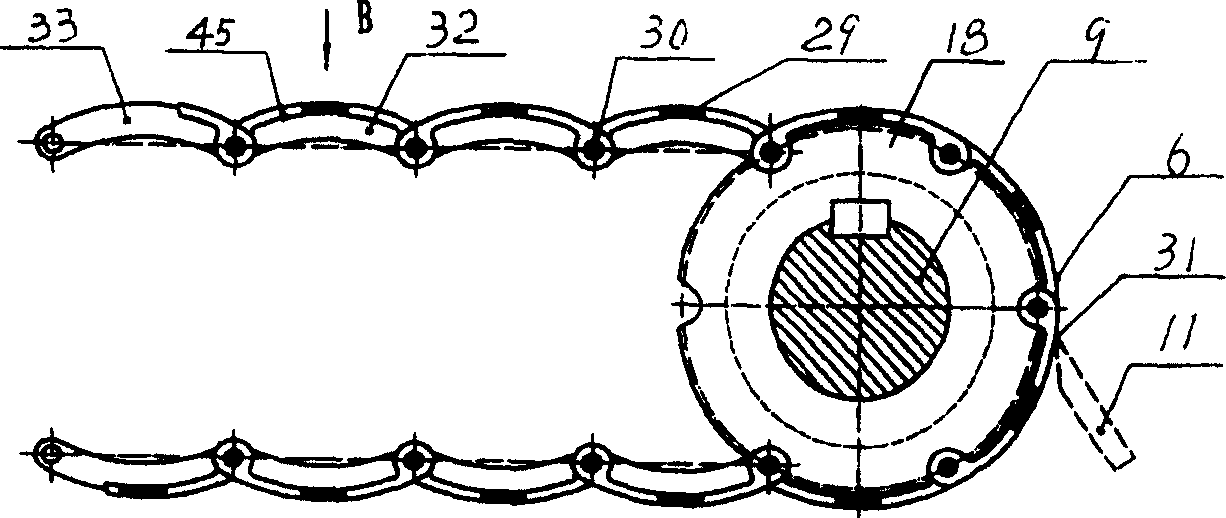

[0028] The difference with Implementation 1 is: in order to meet the needs of the large-load freezing device, the bearing ring and the tension-resistant sheet 36 (see Figure 7 ), the outer circumference radius 39 (see Fig. 8) of the load ring is the same as the outer circumference radius 38 (see Fig. 6) of the pin shaft hole 37 on the convex circular arc working surface shape modular comb member, 30 is movably connected, and the convex arc surface 46 (see Fig. 10 ) of the tensile sheet is lower than the convex arc working surface of the modular comb member 40 on the installed mesh belt. The tooth groove 44 (see FIG. 13 ) of the drive gear 18 corresponds to the position of the anti-tension sheet 36 , and the tooth surface 43 of the drive gear 18 meshes with the bearing ring 35 . In order to increase ventilation and freezing effect, there are ventilation holes 41 and 42 (see Fig. 5 ) on the large-load convex circular arc working surface modular comb-like member 40 (see Fig. 5),...

Embodiment 3

[0030] The difference with embodiment 1 or 2 is: convex circular arc working face shape modular comb member (see image 3 , Fig. 6) is a concave curved surface 45, this structural shape not only reduces the consumption of expensive non-adhesive polytetrafluoroethylene or polyperfluoroethylene propylene, reduces the manufacturing cost, but also helps to reduce the transmission of cold air resistance, improve freezing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com