Uniform-temperature heating furnace

A heating furnace and furnace body technology, applied in the field of uniform temperature heating furnace, can solve the problems of inability to ensure uniform combustion temperature of the furnace body, single heating direction, insufficient installation position, etc., achieve good application and promotion value, improve production efficiency, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

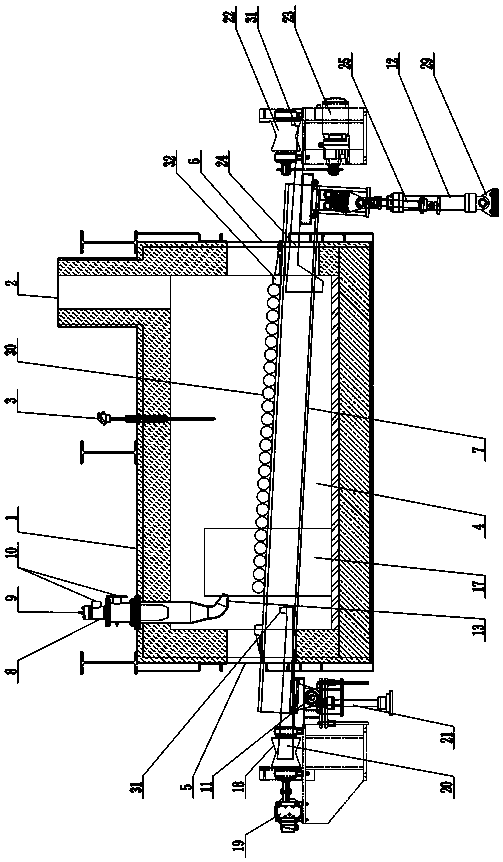

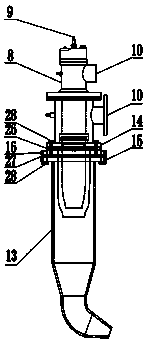

[0019] A kind of uniform temperature heating furnace of the present embodiment, see figure 1 , figure 2 , has a furnace body 1, a flue 2 is opened on the top of the furnace body 1, and a temperature detector 3 and a burner device are installed, a furnace body 4 is opened in the furnace body 1, and a feed port is respectively opened on the left and right sides of the furnace body 4 5 and the discharge port 6, a feed transmission mechanism is provided on the side of the feed port 4, a discharge transmission mechanism is provided on the side of the discharge port 6, a row of girders 7 are arranged side by side in the furnace 4, and there is a gap between two adjacent girders 7 There are gaps, the first and last ends of each girder 7 run through between the feed port 5 and the discharge port 6, the burner device has a burner body 8, and the burner body 8 is provided with a gas inlet 9 and an air inlet 10 , the head end of the girder 7 is set on the fixed shaft 11, the tail end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com