Koji block placing shelf

A technology for placing racks and curved blocks, applied in the field of curved block placing racks, which can solve the problems of high labor intensity, high temperature, high humidity, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

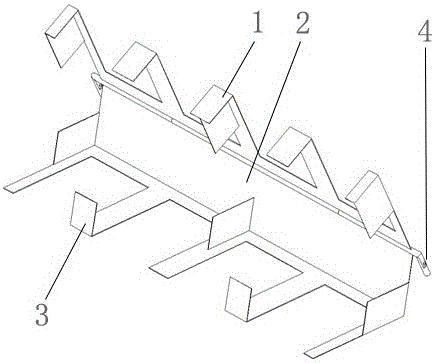

[0021] Such as figure 1 As shown, a curved block placing frame includes a movable end 1 of the placing frame and a fixed end 3 of the placing frame. cavity, the side of the movable end 1 of the placing frame is provided with an elastic swing rod 4 extending to the rear of the spring hinge 2 .

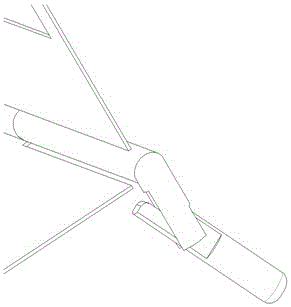

[0022] The swing lever 4 includes two links, a rotating shaft and a return spring, and the two links are rotatably connected by the return spring and the rotating shaft to form a one-way foldable structure, such as figure 2 shown.

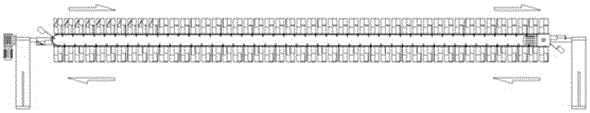

[0023] After the present invention is installed on the integral overturn frame of the curved block, as image 3 shown. The turning positions at both ends of the transmission belt of the integral overturn frame of the curved block are respectively provided with fixed stop rods 5 corresponding to the swing rods 4 .

[0024] The invention has 3 main states:

[0025] 1. Normally closed state. At this time, the fixed end 3 of the placement frame and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com