Can opening machine

A technology of can opener and variable speed motor, which is applied in the field of machinery, can solve the problems of increased cost of can cutting, low work efficiency, and low efficiency, and achieves the effects of saving labor costs, increasing production efficiency, and neat cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

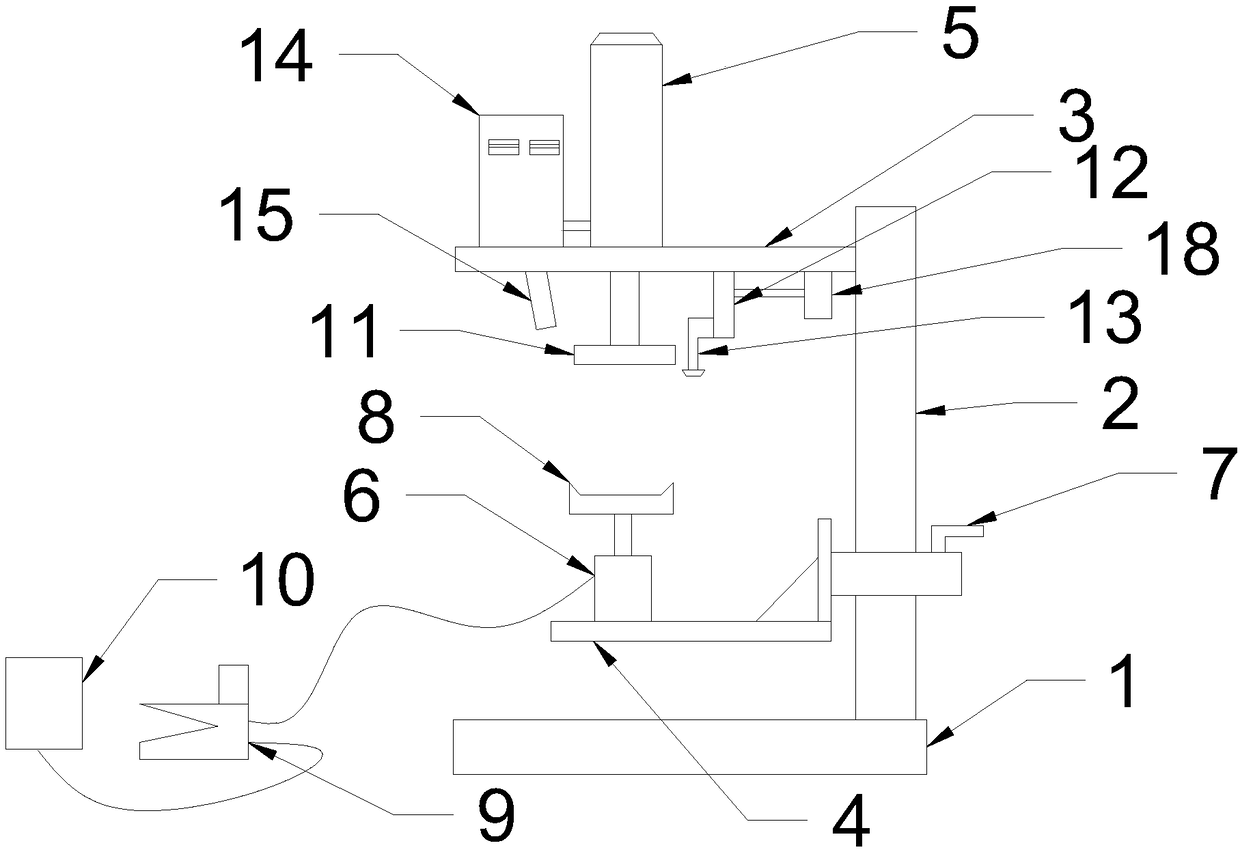

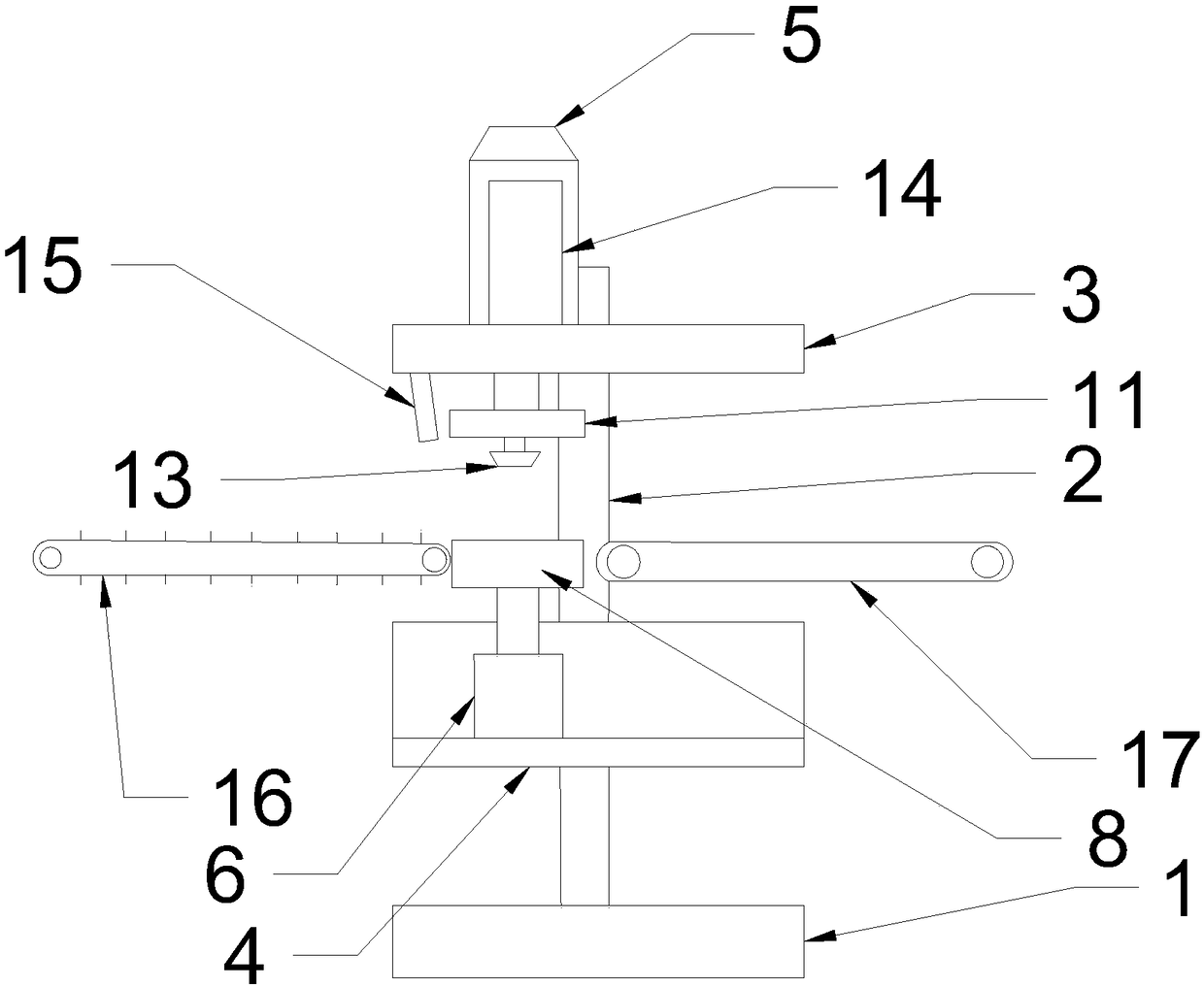

[0017] Such as Figure 1-2 As shown, it includes a base frame, a cylinder 6, a pressure head 11, a variable speed motor 5 and a rotating pallet 8. The base frame includes a bottom base frame 1, an upper base frame 3, a cylindrical base frame 2 and an adjustable base frame 4. When cutting, first Adjust the height of the adjustable base frame 4 by rotating the adjustment handle 7. After the adjustable base frame 4 is adjusted to the position suitable for cutting, the cans are placed on the feeding conveyor belt 16, and the infrared distance measuring sensor 15 detects that there is no For the cut cans, the infrared distance measuring sensor 15 can control the work of the feeding conveyor belt 16 through the electric control box 14. After the conveyor belt 16 transmits the cans to the rotary pallet 8, the infrared distance measuring sensor 15 detects that there is a can being cut on the rotary pallet 8 , the feeding conveyor belt 16 can be controlled to stop working through the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com