Baking equipment

A technology for baking equipment and baking devices, which is applied to baking devices, roasters/barbecue grids, household appliances, etc., can solve problems such as difficulty in ensuring oil quality, inconvenience in cleaning and maintenance, waste of resources, etc., and achieve shortening of baking time. Baking time, easy cleaning and maintenance, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

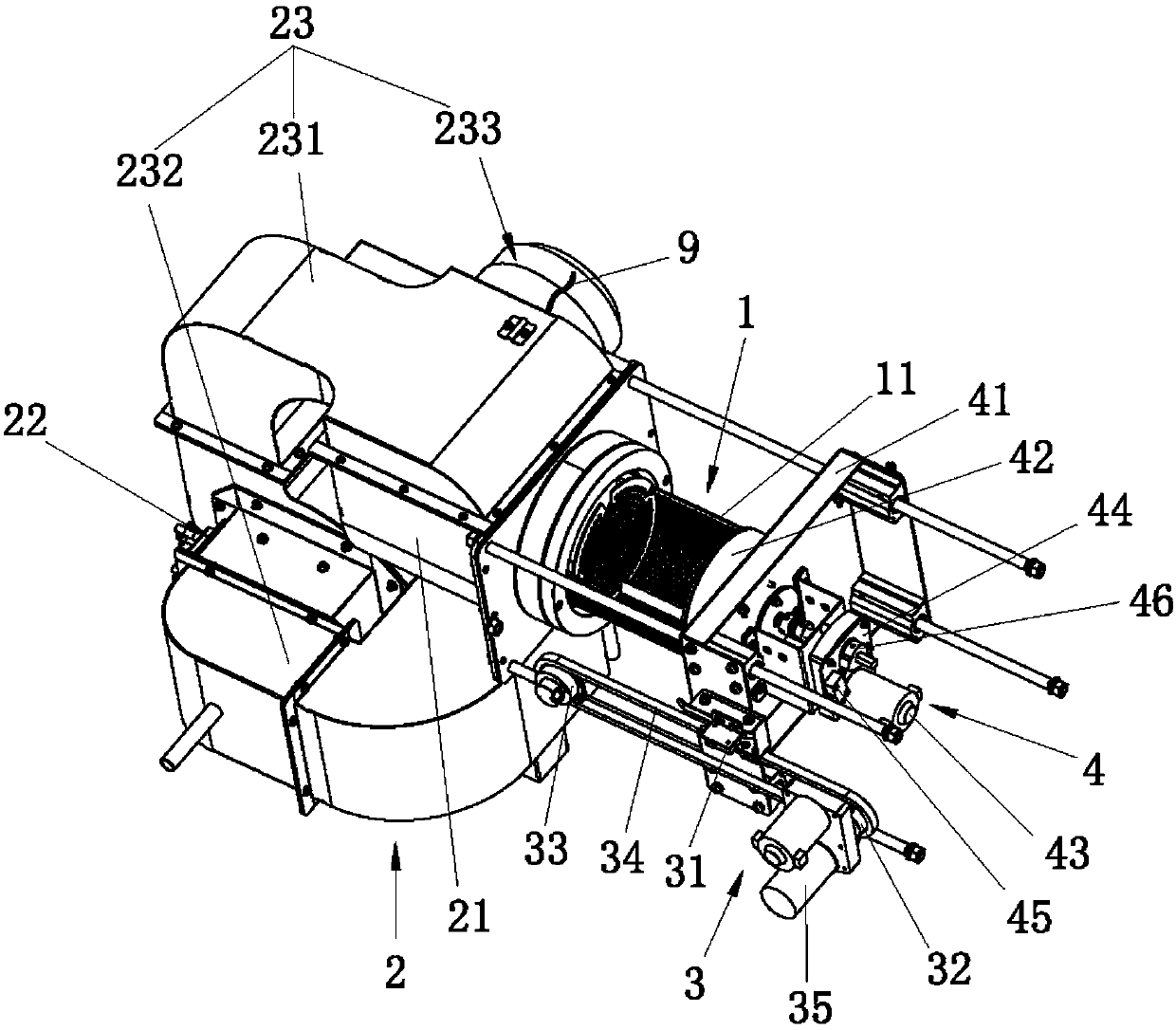

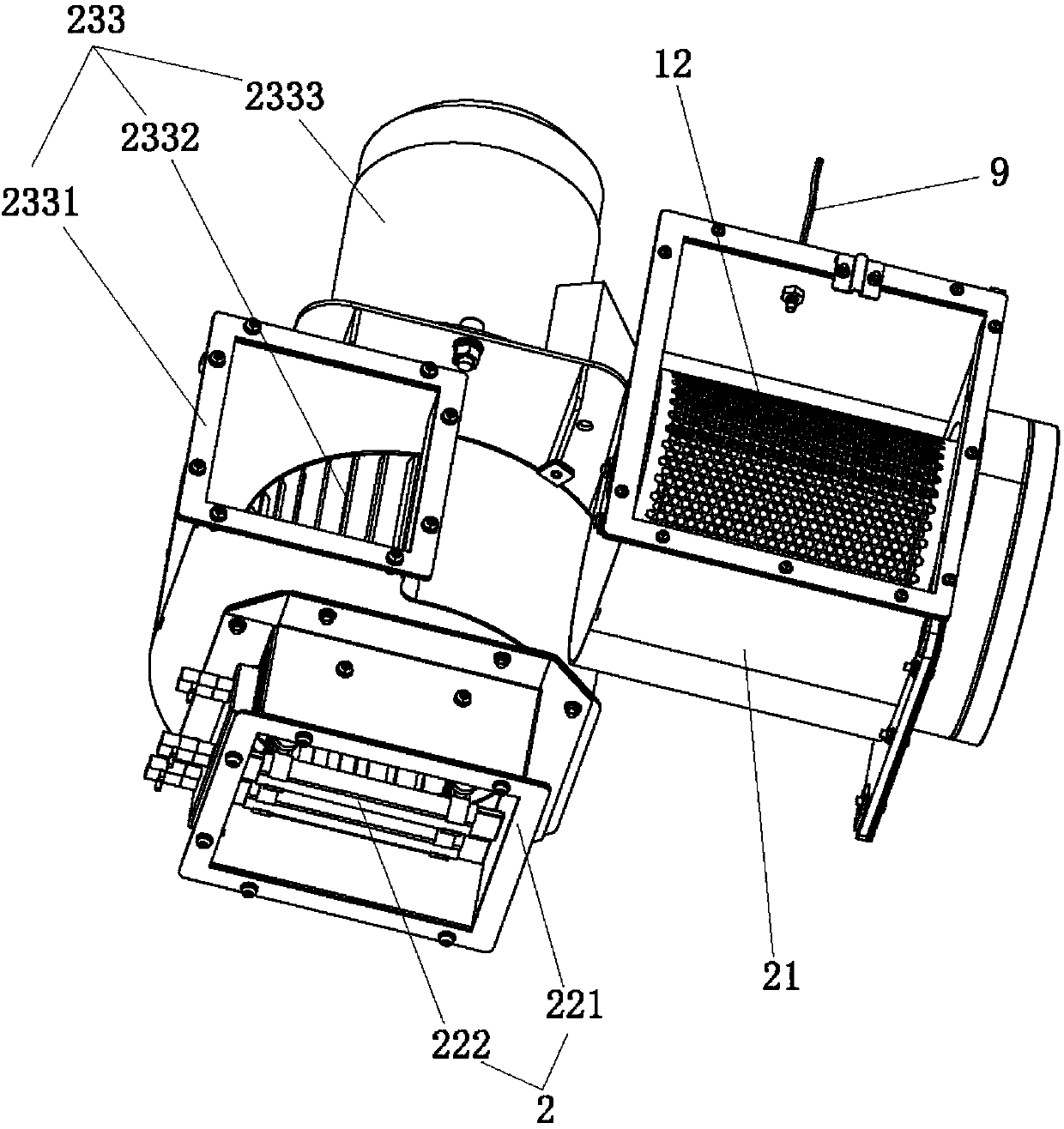

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

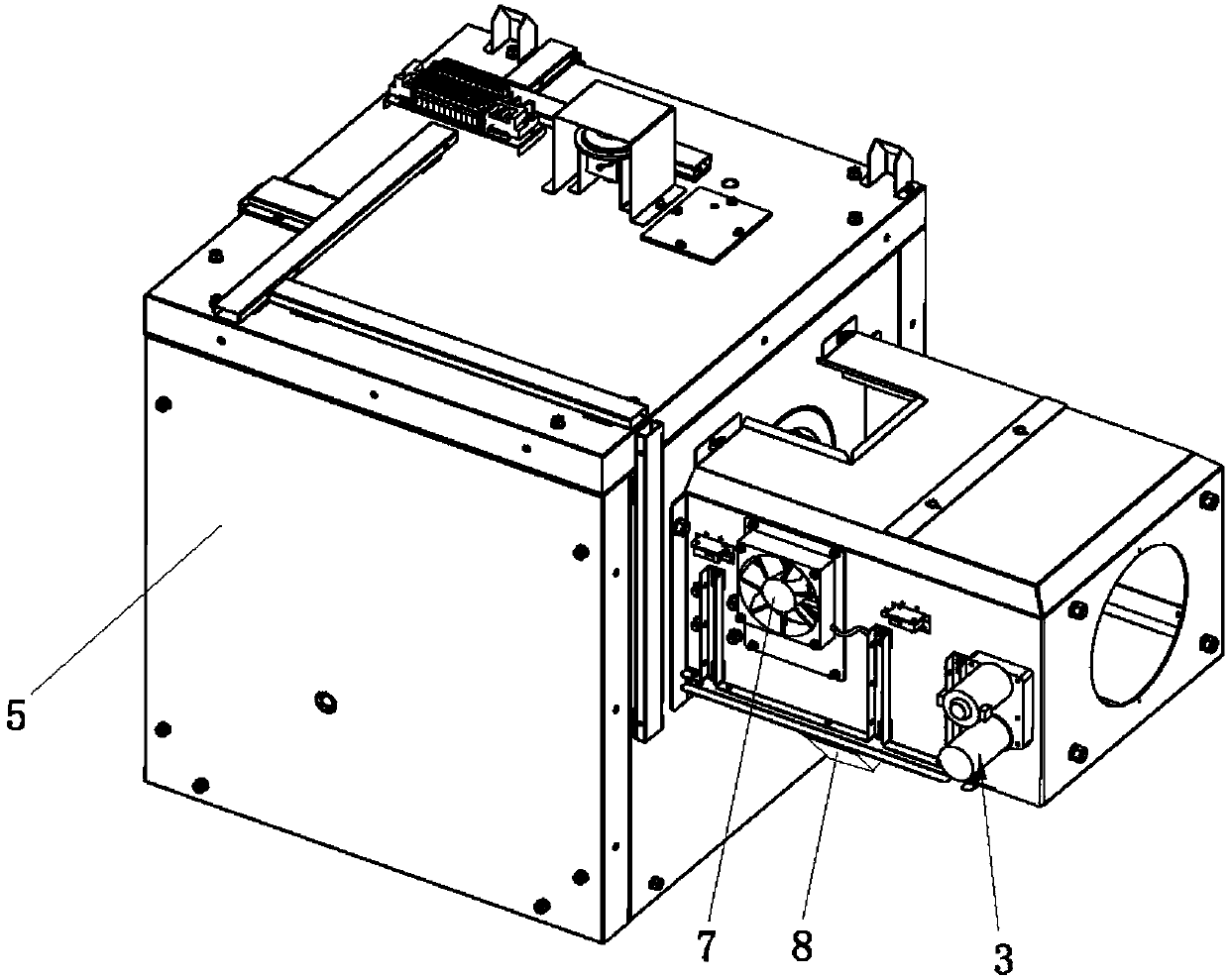

[0034] Such as Figure 1 to Figure 6 As shown, a baking equipment provided by the present invention includes a storage mechanism 1 for storing materials, a baking device 2 for baking materials in the storage mechanism 1, and a baking device 2 for driving the storage mechanism 1 Enter or move out the moving drive mechanism 3 of the baking device 2 and the rotation drive mechanism 4 for driving the storage mechanism 1 to rotate. Specifically, the storage mechanism 1 is provided with a material opening for feeding or discharging, and the material may be French fries, chicken tenders, etc. In this embodiment, French fries are used as an example for illustration.

[0035] In actual use, the Fren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com