Wood crusher

A crusher and wood technology, which is applied in the field of wood processing, can solve the problems of safety hazards, scratches, inconvenient maintenance, etc., and achieve the effect of improving the output capacity, reducing the failure rate, and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

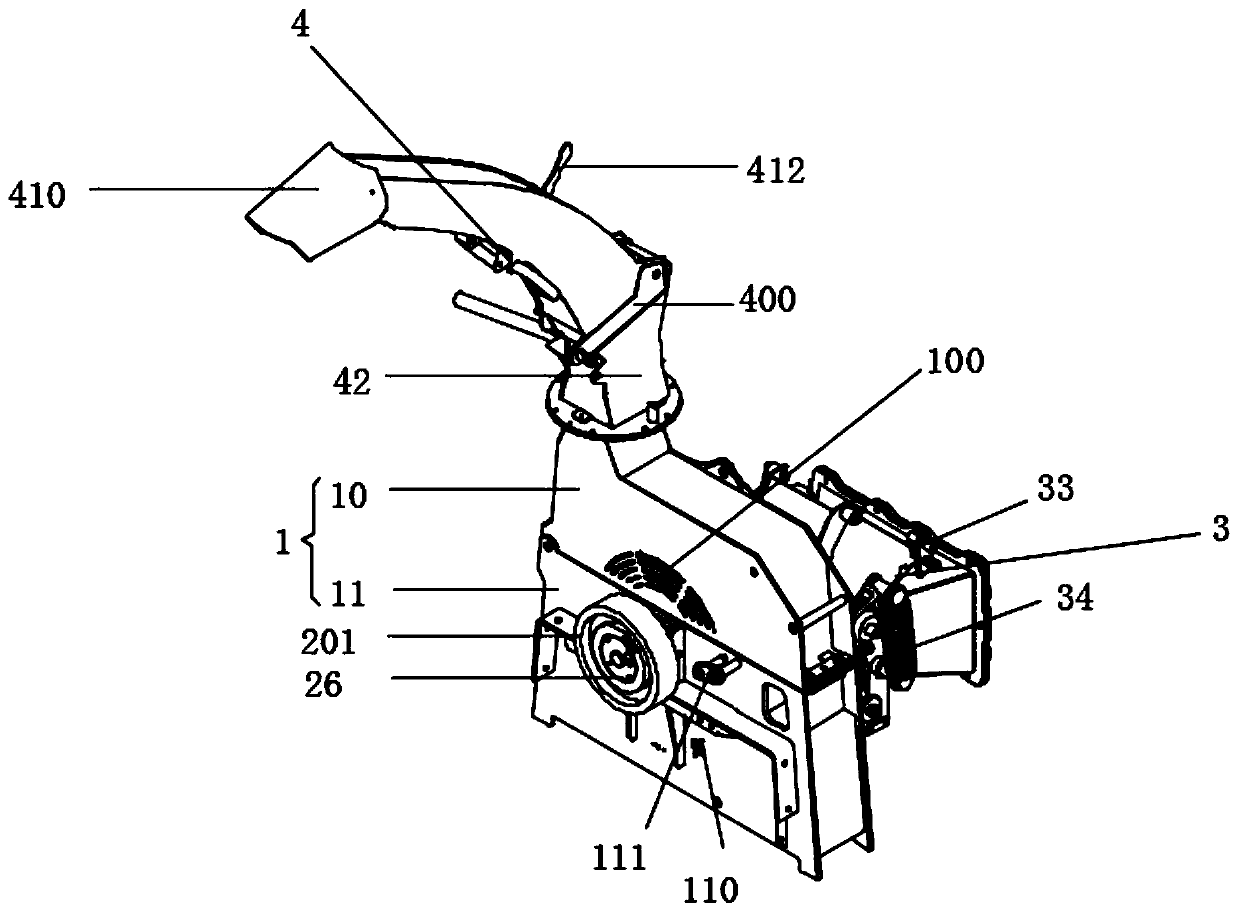

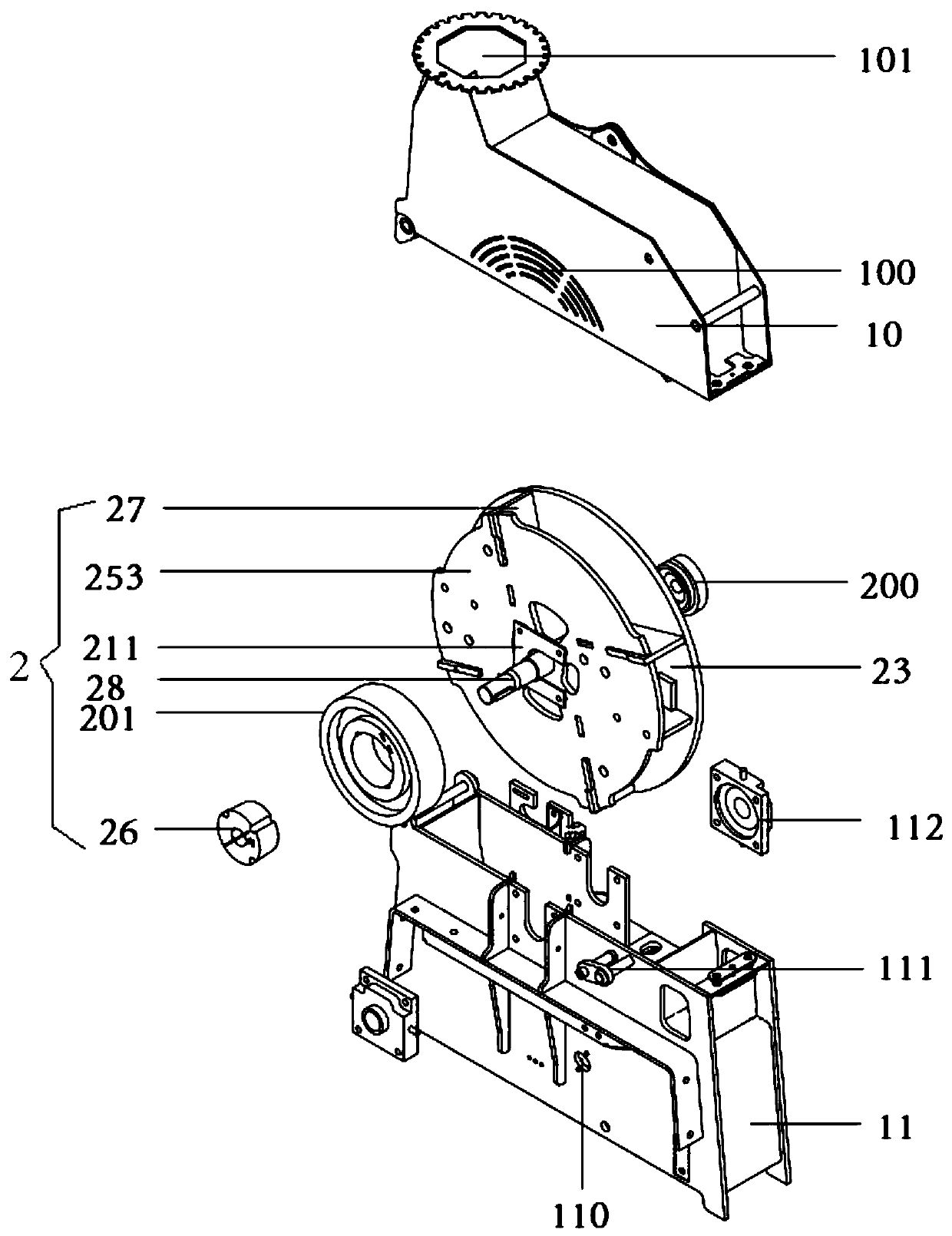

[0050] Please refer to the attached Figure 1-9 , is a wood chipper of the present invention, comprising:

[0051] Housing 1, crushing device 2, feeding device 3 and discharging device 4; crushing device 2 is installed in the housing; housing 1 is provided with a feed port and a discharge port, and the feeding device 3 and the discharging device 4 are respectively It is fixed with the shell and corresponds to the position of the inlet and outlet and communicates with it,

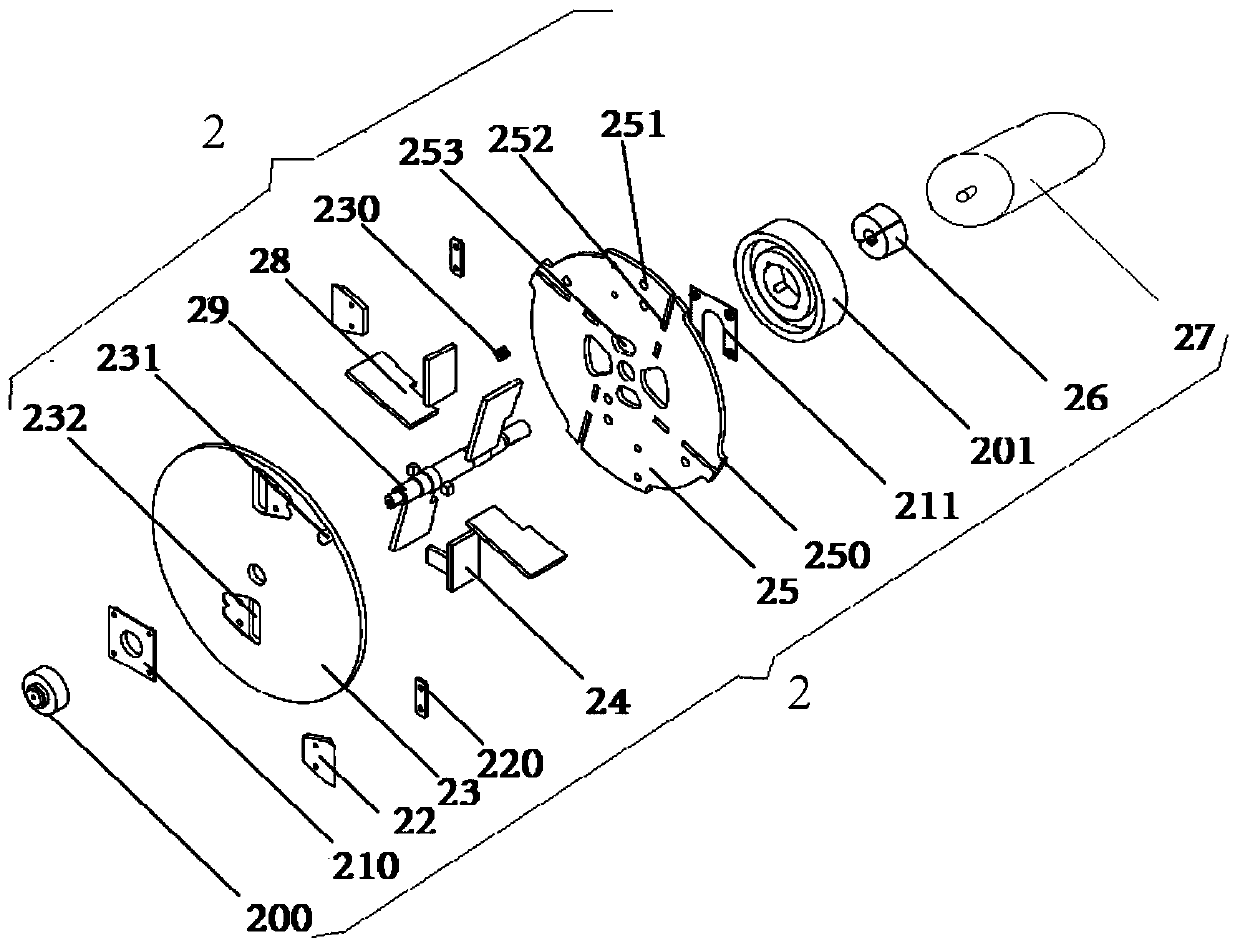

[0052] The crushing device 2 comprises a wheel shaft 29, a moving knife wheel 23, a wind vane wheel 25, a moving knife 22, a wind blade 28, a driving pulley 200, a cutting baffle 24, a power pulley 201, a tapered sleeve 26 and a fixed pulley. Speed motor 27;

[0053] The movable knife wheel 23, the fan wheel 25 and the wheel shaft 29 are set on the wheel shaft 29 in parallel and at intervals, and the wheel shaft 29 is rotationally connected with the housing 1 through bearings fixed on the opposite side w...

example 2

[0091] A wood chipper comprising:

[0092] Housing 1, crushing device 2, feeding device 3 and discharging device 4; crushing device 2 is installed in the housing; housing 1 is provided with a feed port and a discharge port, and the feeding device 3 and the discharging device 4 are respectively It is fixed with the shell and corresponds to the position of the inlet and outlet and communicates with it,

[0093] The crushing device 2 comprises a wheel shaft 29, a moving knife wheel 23, a wind vane wheel 25, a moving knife 22, a wind blade 28, a driving pulley 200, a cutting baffle 24, a power pulley 201, a tapered sleeve 26 and a fixed pulley. Speed motor 27;

[0094] The movable knife wheel 23, the blade wheel 25 and the wheel shaft 29 are set on the wheel shaft 29 in parallel and spaced apart, and the wheel shaft 29 is connected to the housing 1 through the bearings 112 fixedly embedded in the opposite side walls of the housing 1. ; And connect the constant speed motor 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com