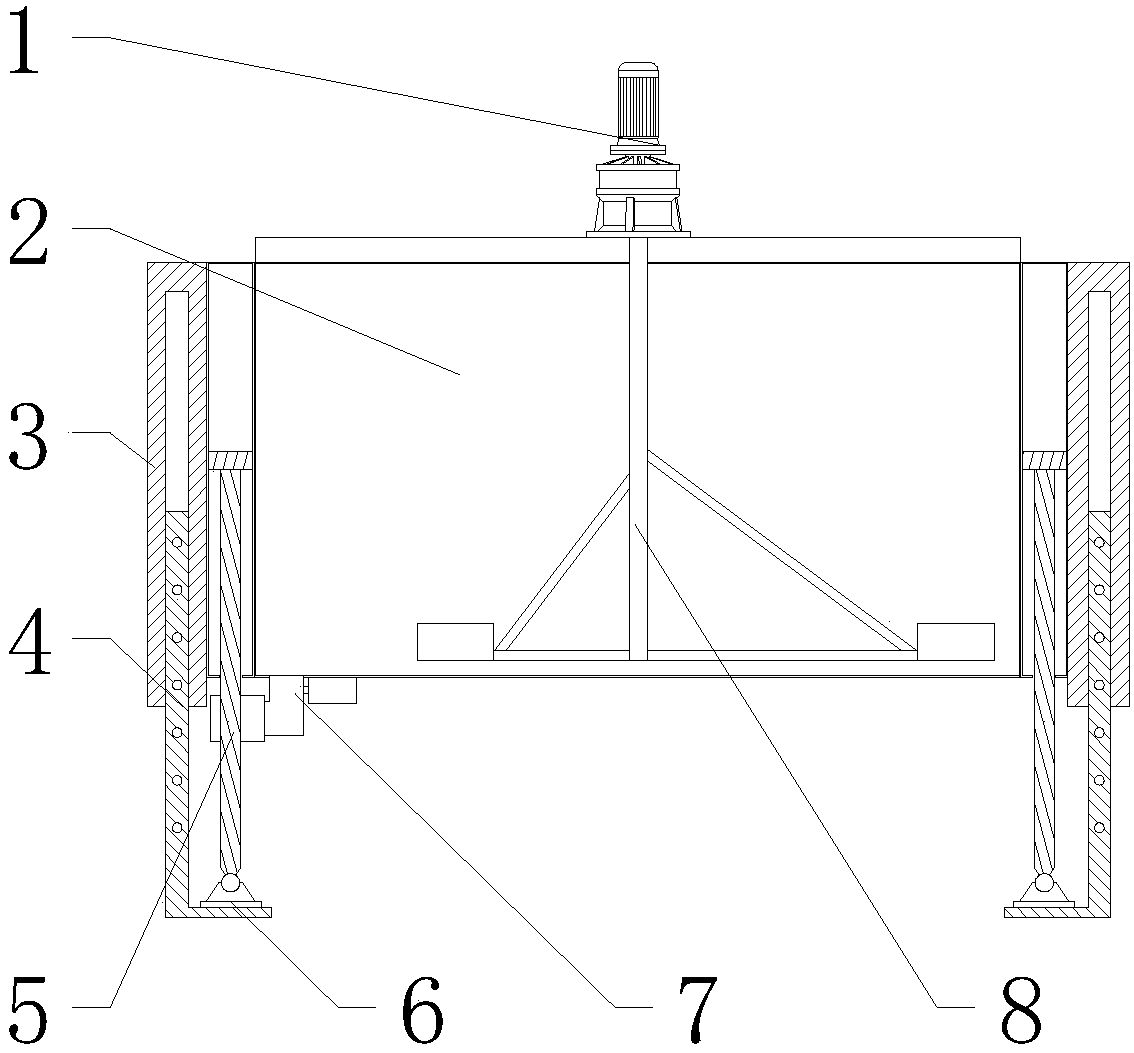

Hydraulic lift type mortar transfer equipment

A transfer equipment, hydraulic lifting technology, used in containers, packaging, transportation and packaging, etc., can solve the problems of reducing the effect of receiving and discharging, unable to expand and contract, unable to lift and so on, to improve the receiving and discharging. effect, improve the sealing effect, the effect of good lifting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

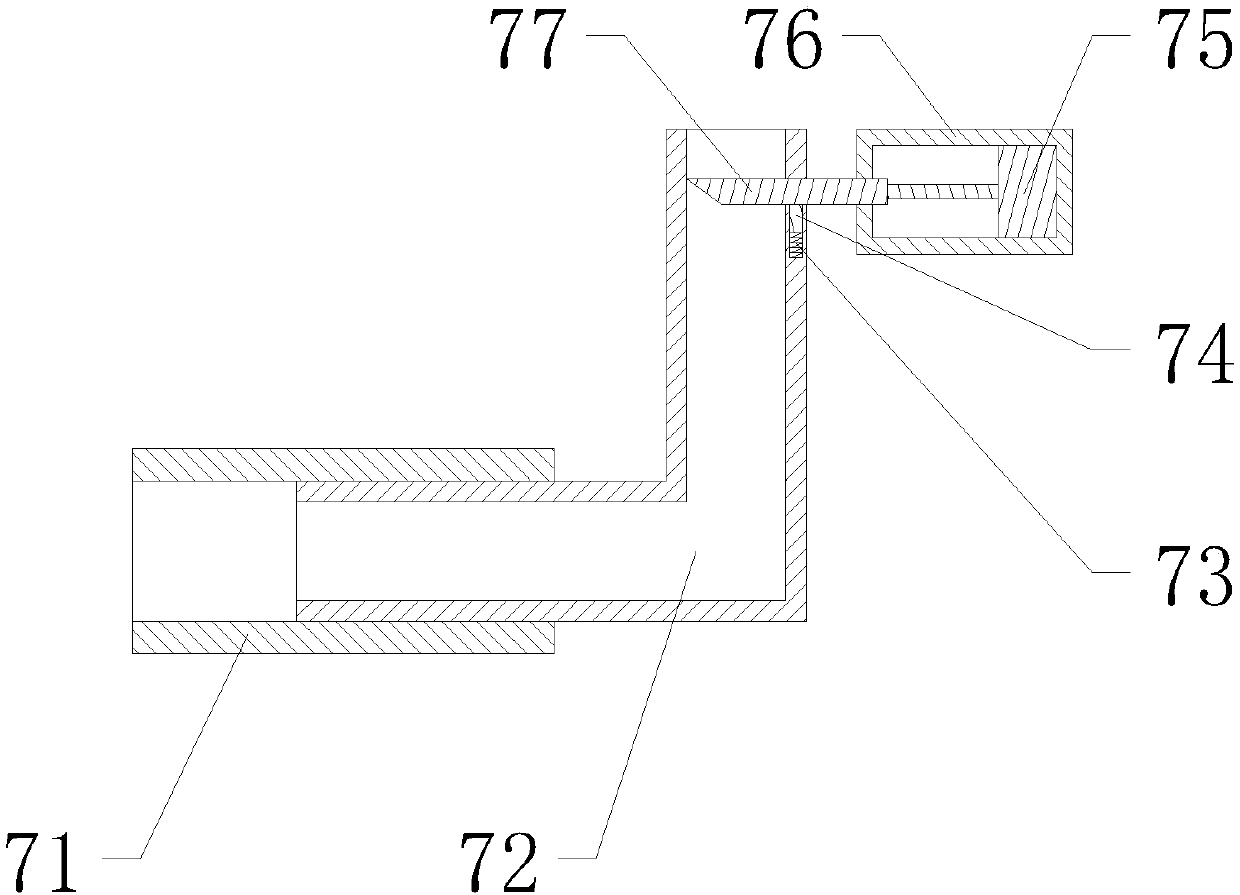

[0024] Specific implementation method: in actual use, the user starts the external oil pump, and the external oil pump works to flush the hydraulic oil into the hydraulic cylinder 5, thereby driving the hydraulic cylinder 5 to move upwards, and the hydraulic cylinder 5 moves upwards to drive the transfer tank 2 and casing 3 at the same time Move upward, when the intermediate tank 2 moves upward to a proper position, the user stops the external oil pump, and then the user holds the latch rod and inserts it into the latch hole on the mechanical leg 4 to support the casing 3. Then the user opens the mixer truck, the mixer truck works and pours the pre-mixed mortar into the transfer tank 2, and then the user starts the stirring motor 1, and the stirring motor 1 works to drive the stirring shaft 8 to rotate, and the stirring shaft 8 rotates to achieve stirring of the mortar. The design can be raised and lowered, and it is also convenient for mixing the mortar.

[0025] After the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com