Double-layer ball milling device for high-purity quartz sand processing

A technology of high-purity quartz sand and double-layer balls, applied in grain processing and other directions, can solve the problems of excessive quartz sand and affect the grinding effect, and achieve the effect of facilitating cutting, improving the ball milling effect, and improving the effect of screening and discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

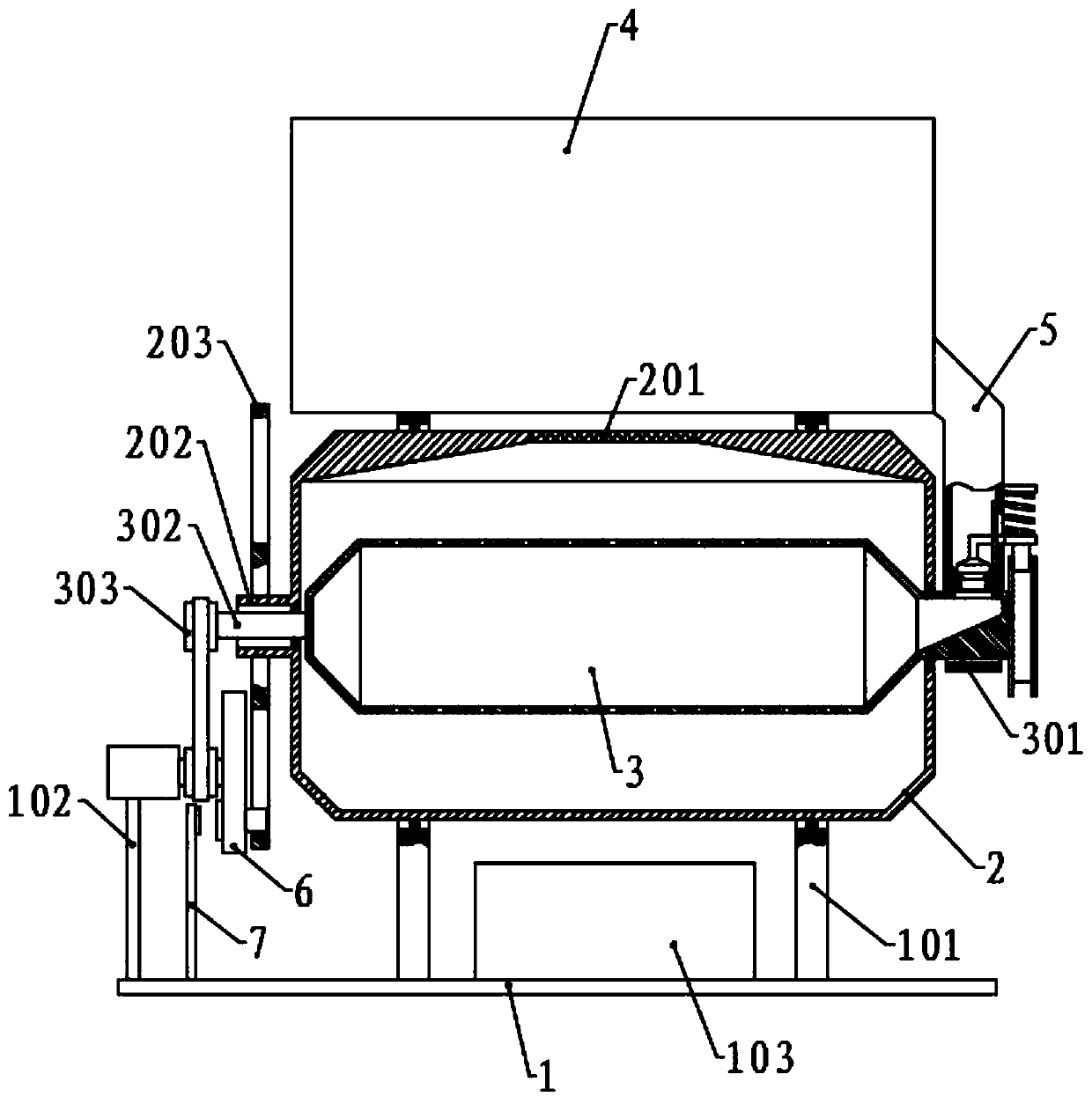

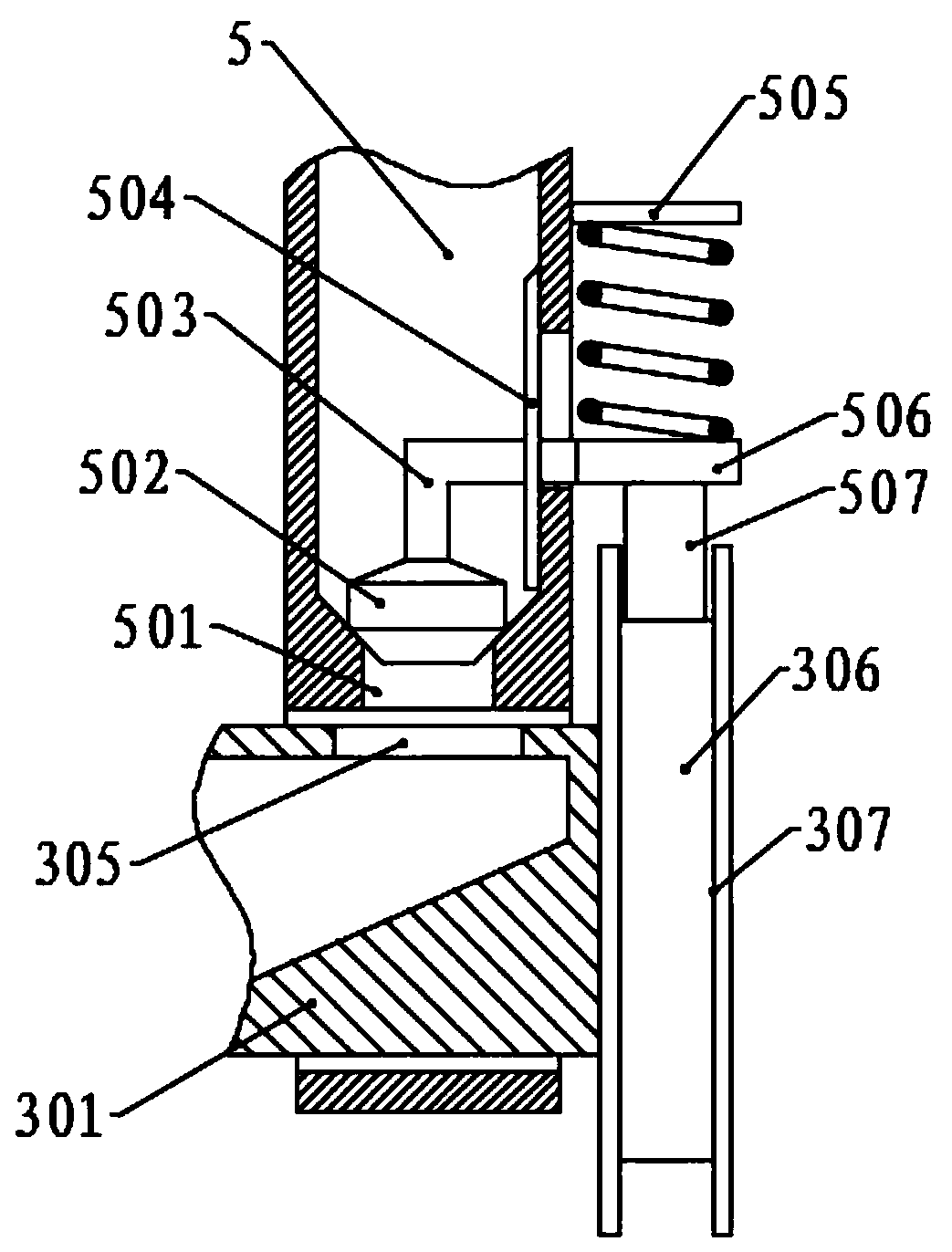

[0033] Please refer to the accompanying drawings, the present invention provides a technical solution: a double-layer ball milling equipment for processing high-purity quartz sand, including a base 1, an outer cylinder 2, an inner cylinder 3 and a material storage box 308, and the inner cylinder 3 and the outer cylinder 2 are provided with ball milling balls, two first support seats 101 are fixed on the right side of the top surface of the base 1, and a second support seat 102 is fixed on the left side of the top surface, and the second support seat 102 is provided with Drive assembly, the inner cylinder 3 is rotatably connected to the center of the inner cavity of the outer cylinder 2, the outer cylinder 2 is rotatably connected to the two first support bases 101, and the storage box 308 is fixed on the top ends of the two first support bases 101 , the feeding pipe 5 is fixed on the storage box 308, the bottom of the feeding pipe 5 is provided with a feed port 501, and a seali...

Embodiment 2

[0044] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that ball grooves are provided on the bottom surface and both side walls of the top block 507, and balls are arranged in the ball grooves, and the balls and the side plates 307 and the rotation The wheel surface of the wheel 306 is in contact, thereby limiting the position of the top block 507 through the side plate 307 and the rotating wheel 306, reducing the friction of the top block 507 when moving relative to the side plate 307 and the rotating wheel 306, and improving the flexibility of movement.

Embodiment 3

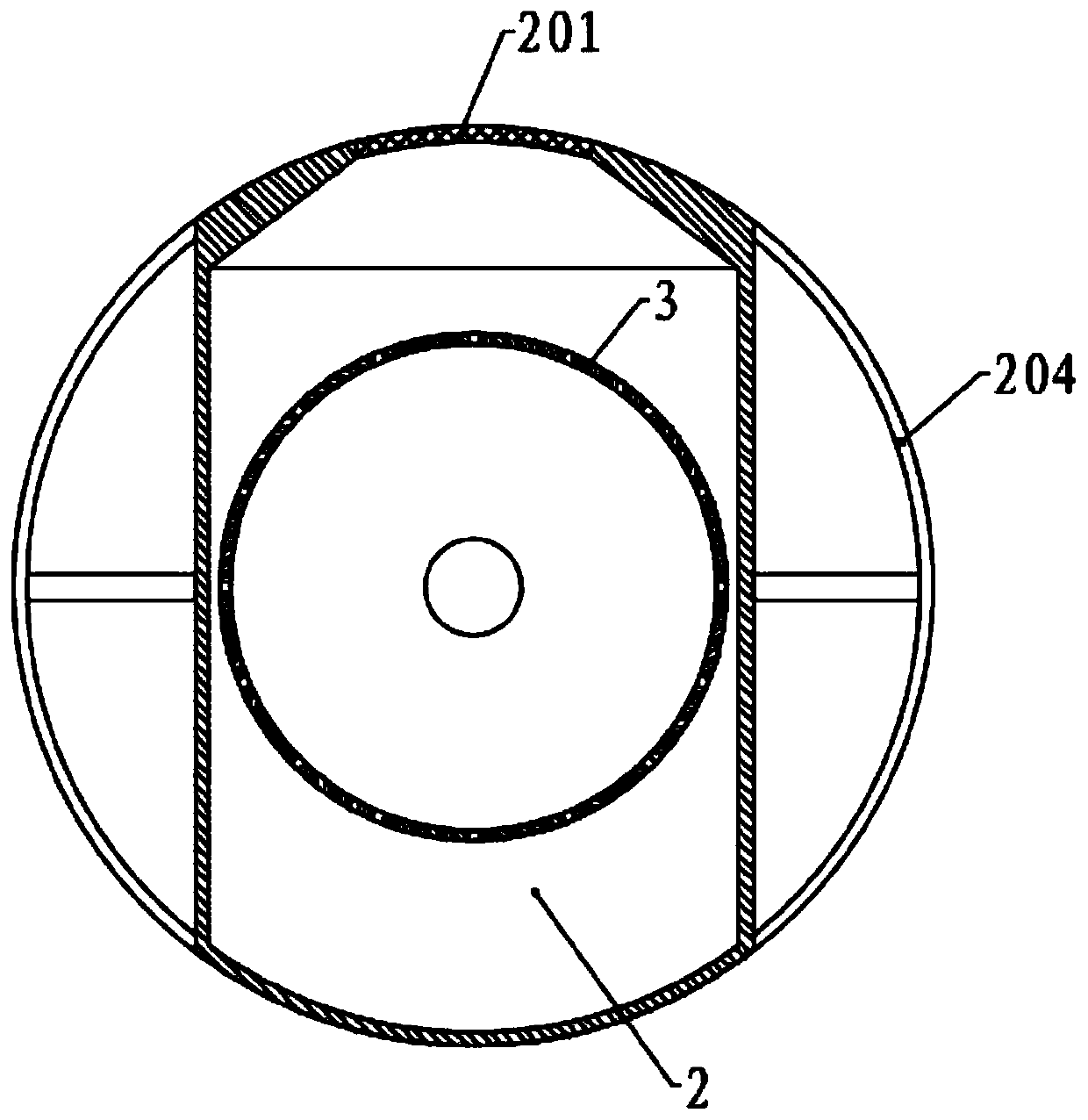

[0046] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the bottom and the top plate of the outer cylinder 2 are both arranged in a circular arc shape, and the top surface of the inner cavity is arranged in an inverted bucket shape, facing the screen 201 The place is inclined so that when the screen 201 rotates to the bottom, the quartz sand can avoid quickly moving toward the screen 201 through a bucket shape. The two side walls of the outer cylinder 2 are set to be vertical, and the vertical side walls correspond to The positions of the first support bases 101 are respectively fixed with arc-shaped plates 204 by connecting rods. The outer side walls of the arc-shaped plates 204 form a complete circle with the arc side walls of the outer cylinder 2, and are connected with the first support base 101. Rotationally connected, and the width of the arc plate 204 is greater than that of the rotating seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com