Concrete sewage sand and gravel separation equipment

A technology for sand and gravel separation and concrete, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as reducing the separation efficiency of sand and gravel, and achieve the effect of improving separation efficiency and improving discharge effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-6 The application is described in further detail.

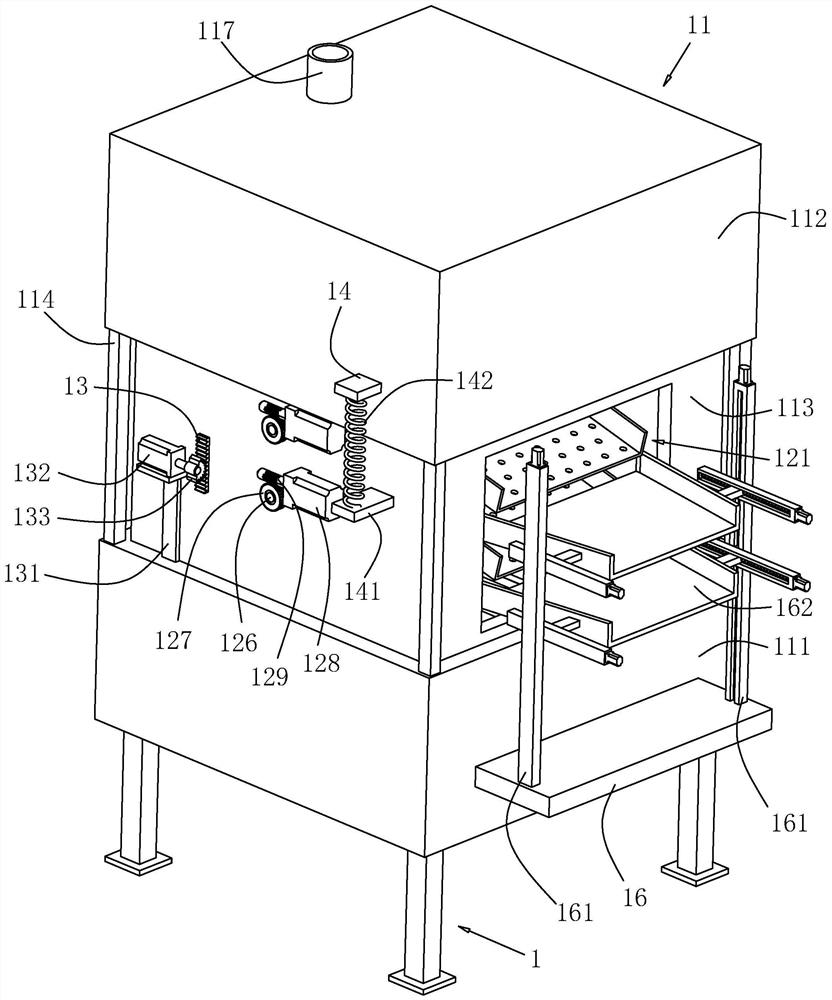

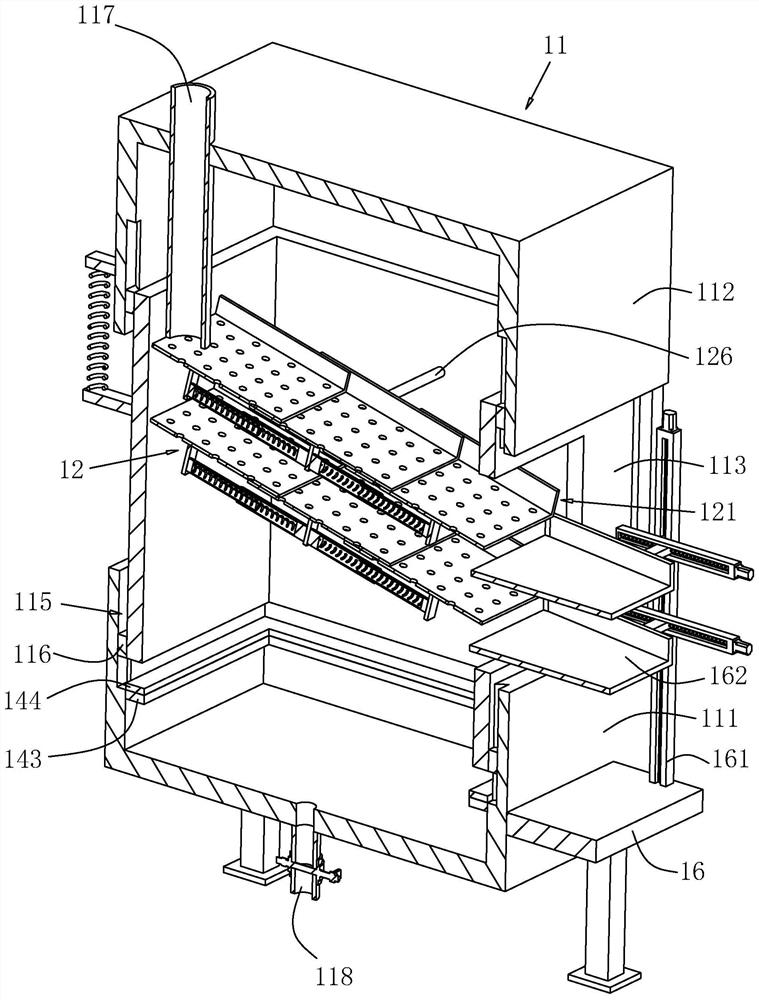

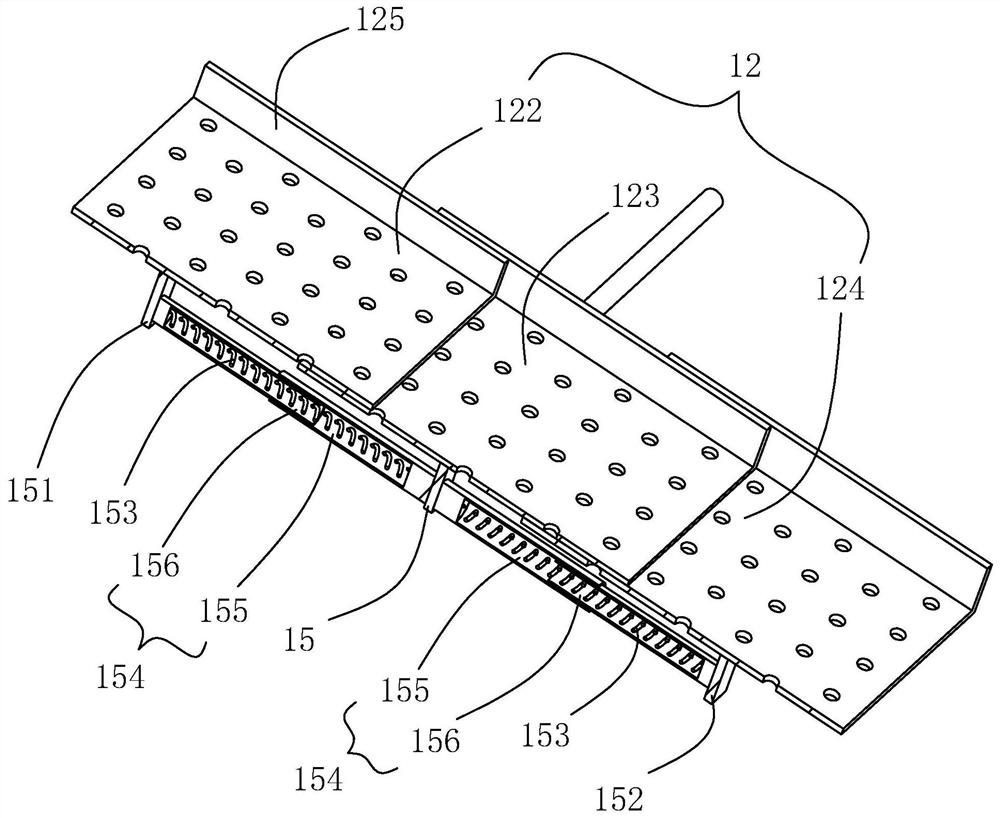

[0038] The embodiment of the application discloses a concrete sewage sand and gravel separation equipment. combine figure 1 with figure 2 , a kind of concrete sewage sand stone separation equipment, comprises frame body 1, and frame body 1 comprises four support rods, and the end of each support rod is all provided with support plate, and frame body 1 is provided with box body 11, and box body 11 Including a first fixed box 111, a second fixed box 112 and a sliding box 113, the first fixed box 111 is fixedly arranged on the frame body 1, the second fixed box 112 and the first fixed box 111 are mutually spaced, and the second fixed box 112 and the first fixed box 111 and at the four corners of the second fixed box 112 are provided with connecting rods 114, the connecting rods 114 are used to support the second fixed box 112, the inner walls of the first fixed box 111 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com