Production apparatus and method of concrete additive

A technology of production equipment and additives, applied in chemical instruments and methods, feeding devices, chemical/physical/physicochemical processes, etc., can solve problems such as being unable to cope with home construction and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

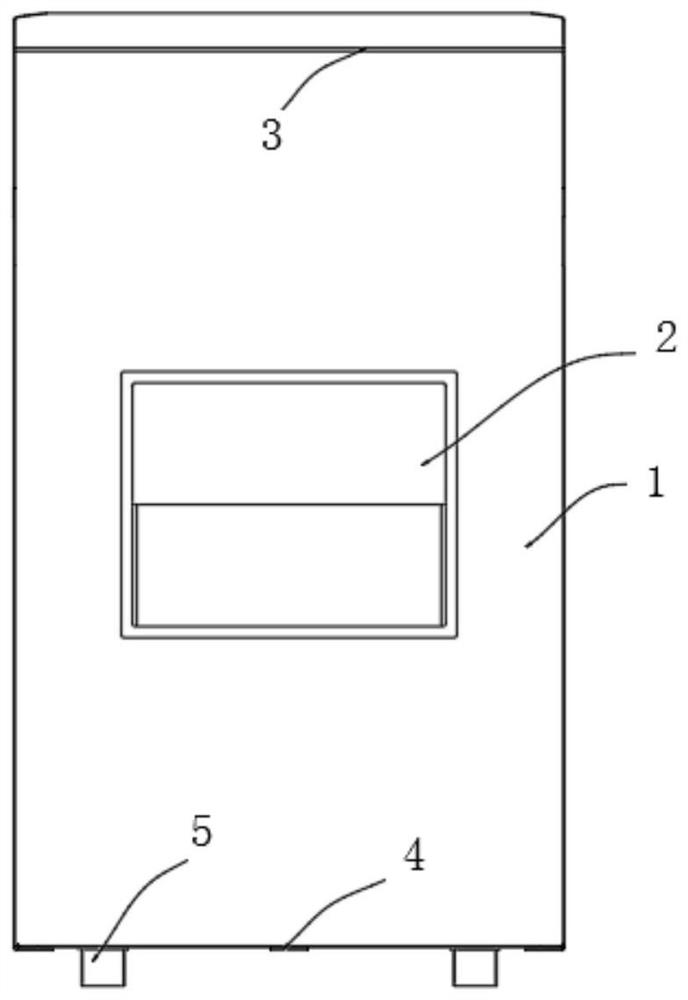

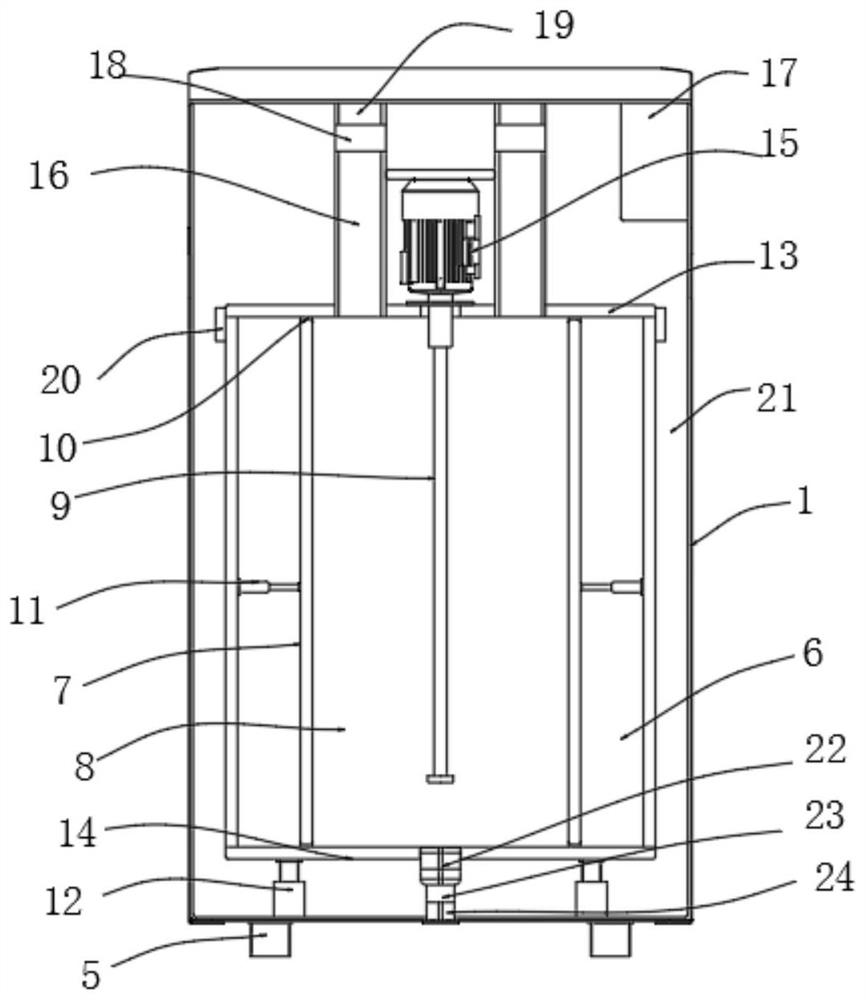

[0023] like figure 1 , figure 2 As shown, a production equipment for concrete additives includes a device main body 1, a control panel 2 is connected to the outer surface of the device main body 1, a feeding device 3 is connected to the upper end surface of the device main body 1, and the device main body 1 The lower end surface is provided with a discharge device 4 and a leg member 5, and the inside of the device main body 1 is provided with a stirring device and a control machine 17, and the input end of the control machine 17 is connected with the output end of the control panel 2. The output end of the control machine 17 is respectively connected with the feeding device 3, the discharging device 4, and the stirring device, and the stirring device includes a mixing chamber 8, and the mixing chamber 8 is arranged in the inside of the device main body 1. The volume of the mixing chamber 8 is variable, and the mixing chamber 8 can be inclined relative to the bottom plate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com