Wet iron ore powder bin device capable of preventing arching and arch breaking and application method

A technology of iron ore powder and silo, which is applied in the field of metallurgy, and can solve problems such as damage to feed balance, increased workload of operators, and damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

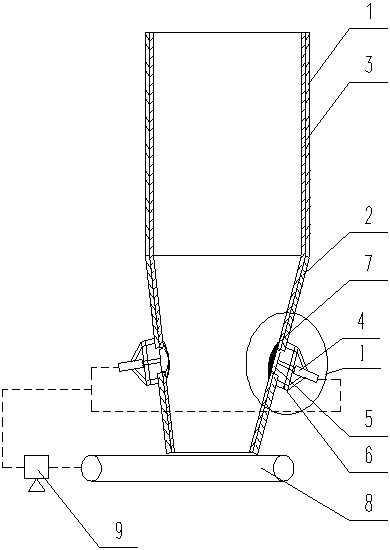

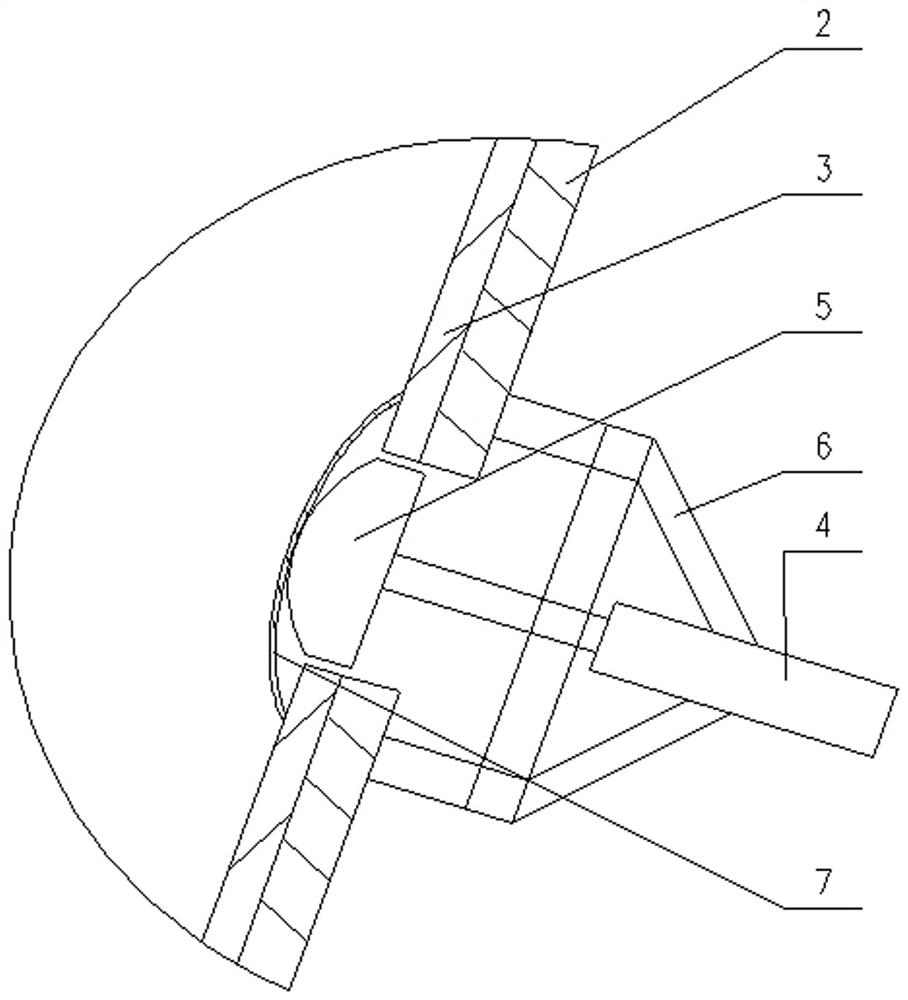

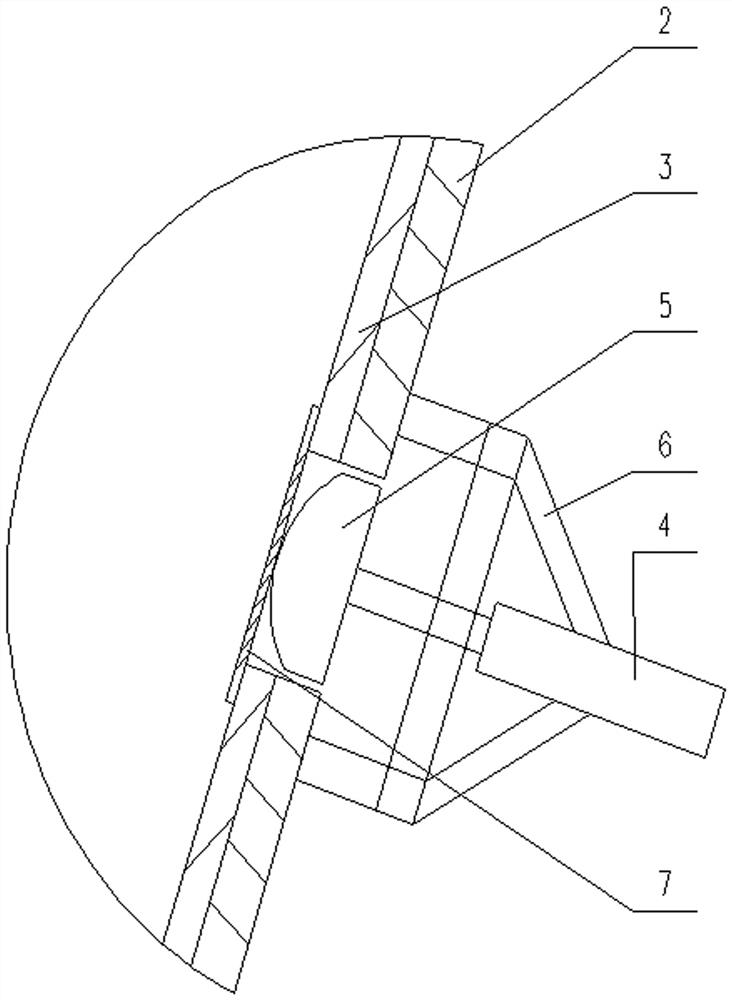

[0032] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

[0033] like figure 1 As shown, a wet iron ore powder silo device capable of preventing arching and breaking, includes a straight barrel 1, a cone 2, a liner 3, a driving device 4, a drum hammer 5, a bracket 6, and a tympanic membrane. 7. Weighing belt scale 8, the straight barrel 1 of the silo is cylindrical, the lower end of the straight barrel 1 of the silo is connected with the upper end of the cone 2 of the silo, and the lower end of the cone of the silo is the discharge port; The cross-section of the mouth is trapezoidal; the silo cone is an asymmetric structure with inconsistent side taper, that is, the eccentricity of the silo cone is asymmetrical, and the center of the outlet of the silo cone is not on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com