A circuit board 3D printing method with spatial three-dimensional circuit

A space three-dimensional, 3D printing technology, applied in the field of 3D printing, can solve the problems of shape structure design limitation, circuit board space occupation, high cost of composite process, achieve fast forming speed, optimize shape structure, and solve the effect of low space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

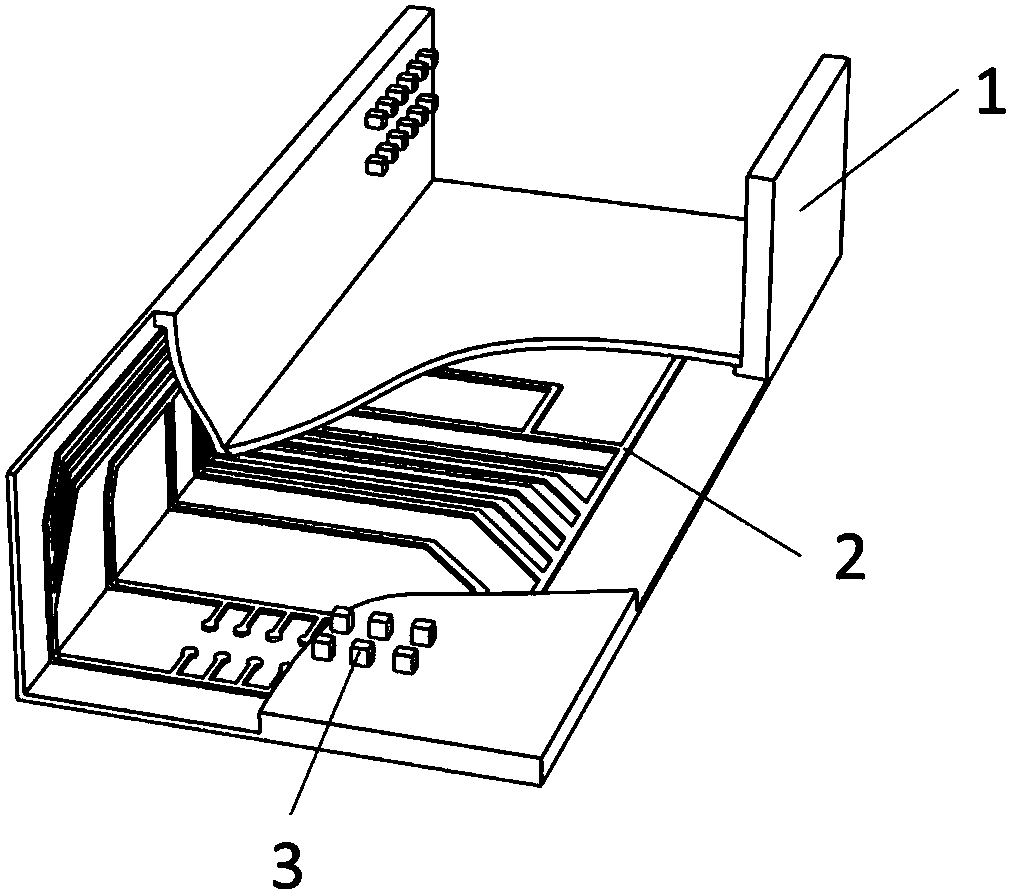

[0036] 1) Use 3D modeling software to design such as figure 1 The structural model of the cuboid-shaped part product (belonging to the circuit board) shown, and the circuit lines distributed with the structural shape, wherein 1 is the product structure part, 2 is the circuit line part, and 3 is the interface for chip insertion;

[0037] 2) Using slicing software to slice the model layer by layer, each layer thickness is 0.1mm, and identify the product structure part 1 and the circuit circuit part 2 in each layer in the slicing information;

[0038] 3) Input the structural information and circuit line information identified by each layer to the FDM terminal equipped with dual nozzles. The dual nozzles (built-in heating rod brass nozzles, nozzle diameter range 0.2mm-0.4mm) include front nozzles and rear nozzles The work is controlled by the control system. The material in the feeding system of the front nozzle is ABS wire with a diameter of 1.8mm; the feeding system of the rear ...

Embodiment 2

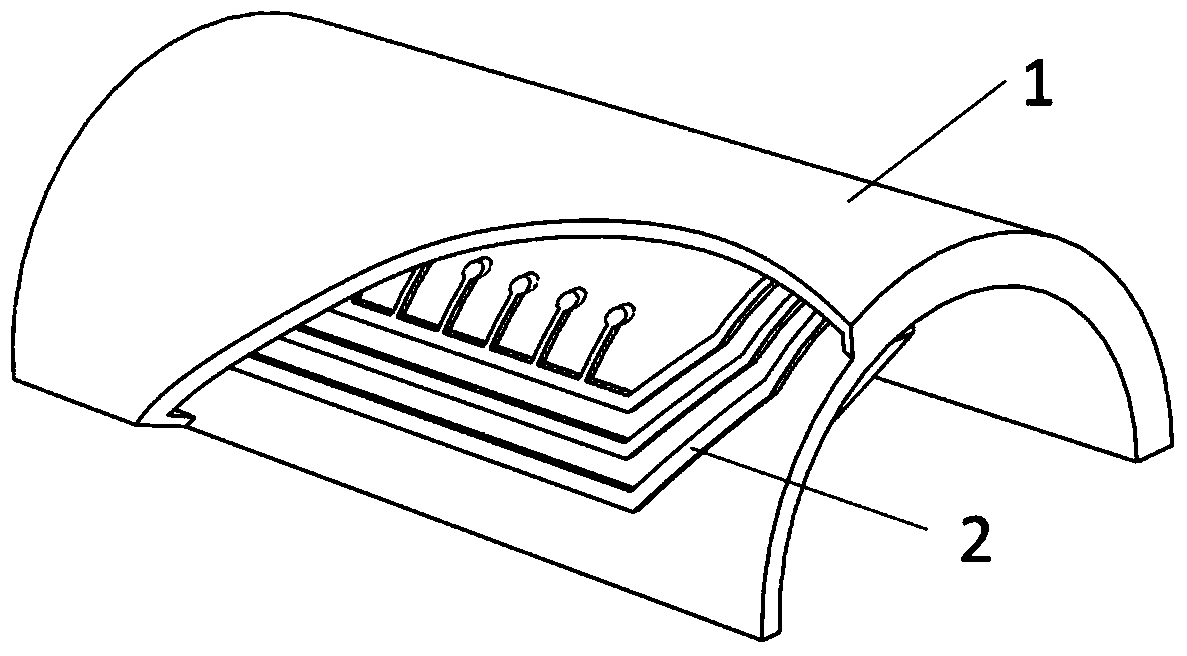

[0042] 1) Use 3D modeling software to design such as figure 2 The structural model of the semi-cylindrical part product (belonging to the circuit board) shown, and the circuit lines distributed with the structural shape, wherein 1 is the structural part of the model, and 2 is the circuit line part;

[0043] 2) Using slicing software to slice the model layer by layer, each layer thickness is 0.1mm, and identify the product structure part 1 and the circuit circuit part 2 in each layer in the slicing information;

[0044] 3) Input the structural information and circuit line information identified by each layer to the FDM terminal equipped with dual nozzles. The dual nozzles (built-in heating rod brass nozzles, nozzle diameter range 0.2mm-0.4mm) are divided into front nozzles and rear nozzles. The nozzle is controlled by the control system. The material in the feeding system of the front nozzle is nylon wire with a diameter of 1.6mm; the feeding system of the rear nozzle is silve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com