Recovery method for waste of 3D printer

A 3D printer and waste recycling technology, applied in the field of 3D printers, can solve the problems of environmental pollution, discarding, defective products, etc., and achieve the effect of reasonable system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

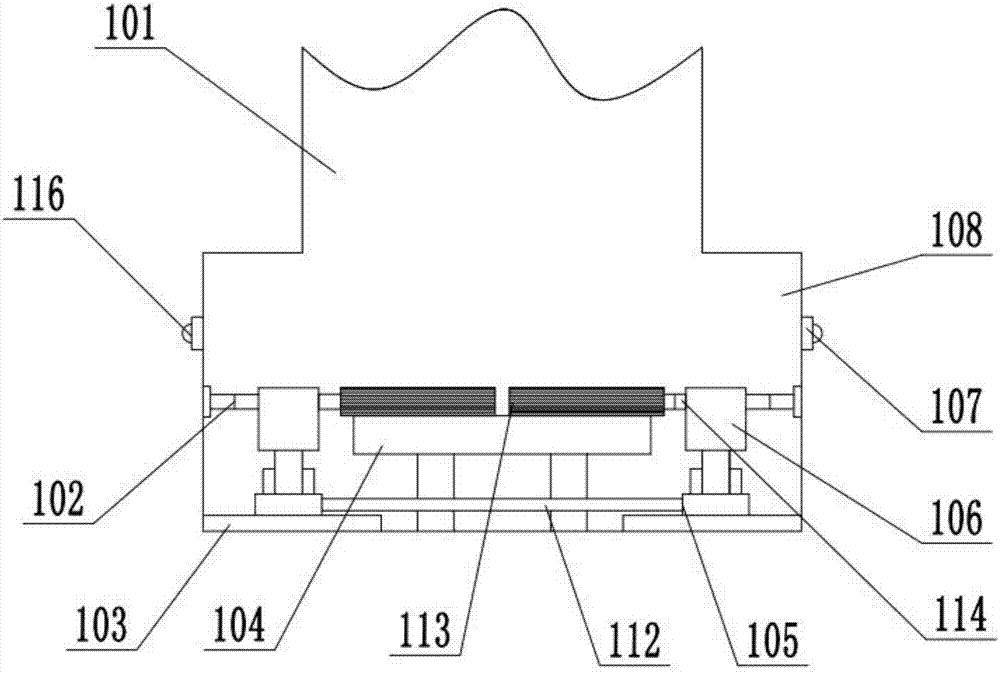

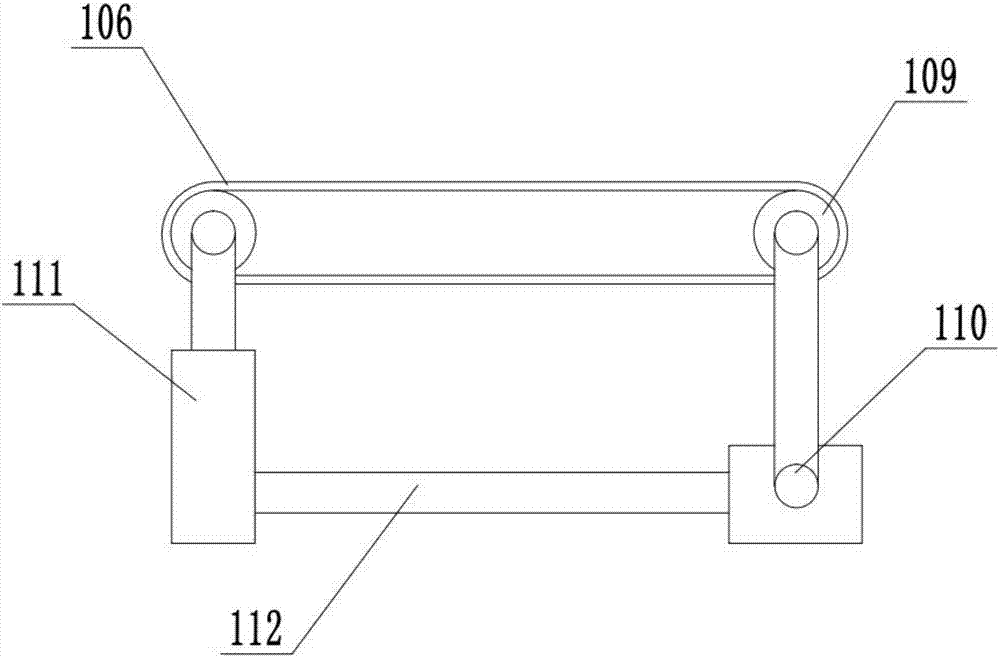

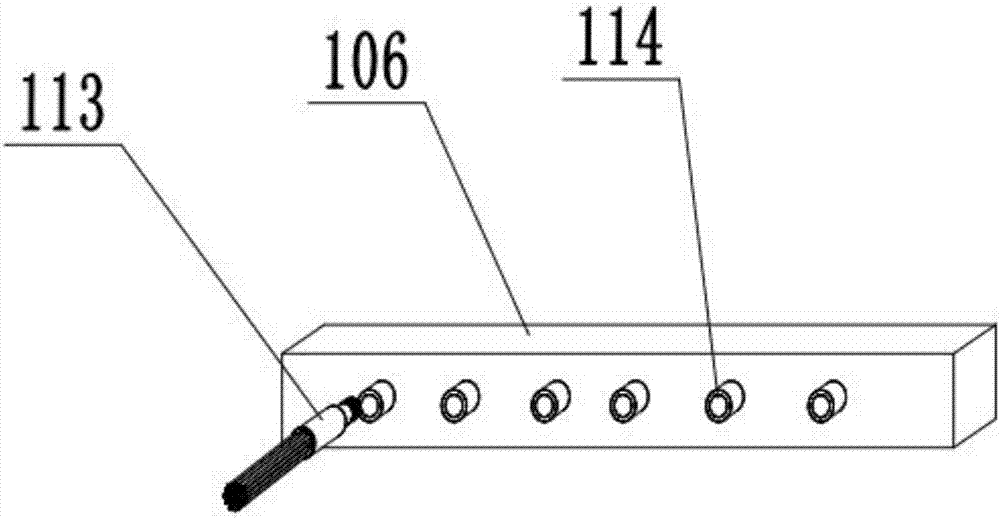

[0051] Such as Figure 16 As shown, the 3D printer waste recycling system of this embodiment includes a waste storage device 1, a waste recycling device 2, a waste cooling device 3, a waste crushing device 4, a crushed waste conveying device 5 and a re-injection molding device 6;

[0052] The printed waste is stored in the waste storage device 1, and is recycled and stored by the waste recycling device 2; when it needs to be reused, the printed waste is cooled by the waste cooling device 3, so that the texture of the printed waste becomes brittle, and then it is taken out and put away. The waste is processed into the waste crushing device 4 to be processed into particles, and then the particles are transported to the injection heat pipe of the re-injection molding device 6 by the crushed waste conveying device 5 to be extruded into reused pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com