Trash burning treatment device

A processing device and a waste burning technology, applied in the combustion method, combustion type, combustion technology mitigation and other directions, can solve the problem of unsatisfactory waste combustion effect, and achieve the effect of saving resources, avoiding waste clogging and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

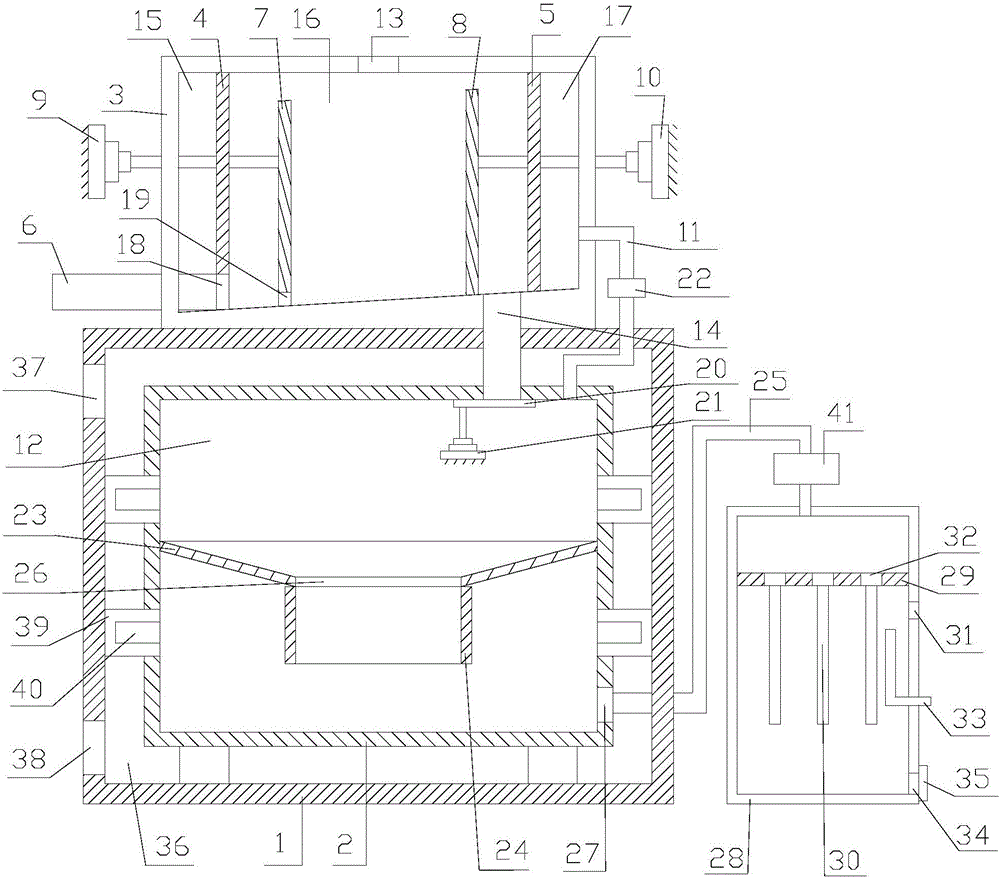

[0050] refer to figure 1 :

[0051] A garbage burning treatment device proposed by the present invention includes an outer casing 1, an inner casing 2, a box body 3, a first partition 4, a second partition 5, a sewage pipe 6, a first moving plate 7, a second moving plate Plate 8, first power unit 9, second power unit 10, connecting pipe 11, rotating plate 20, third power unit 21, first valve 22, first partition plate 23, annular baffle 24, exhaust pipe 25 , a water tank 28, a second partition plate 29, a plurality of water pipes 30, a drain pipe 33, a second valve 35, a plurality of connecting columns 39, and an exhaust fan 41.

[0052] The inner casing 2 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com